Evaporation crucible and evaporation equipment

A technology of evaporation and crucible, which is applied in the field of equipment manufacturing, can solve the problems of unstable evaporation rate and poor film quality of evaporation crucible, and achieve the effects of reducing deterioration, improving stability and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

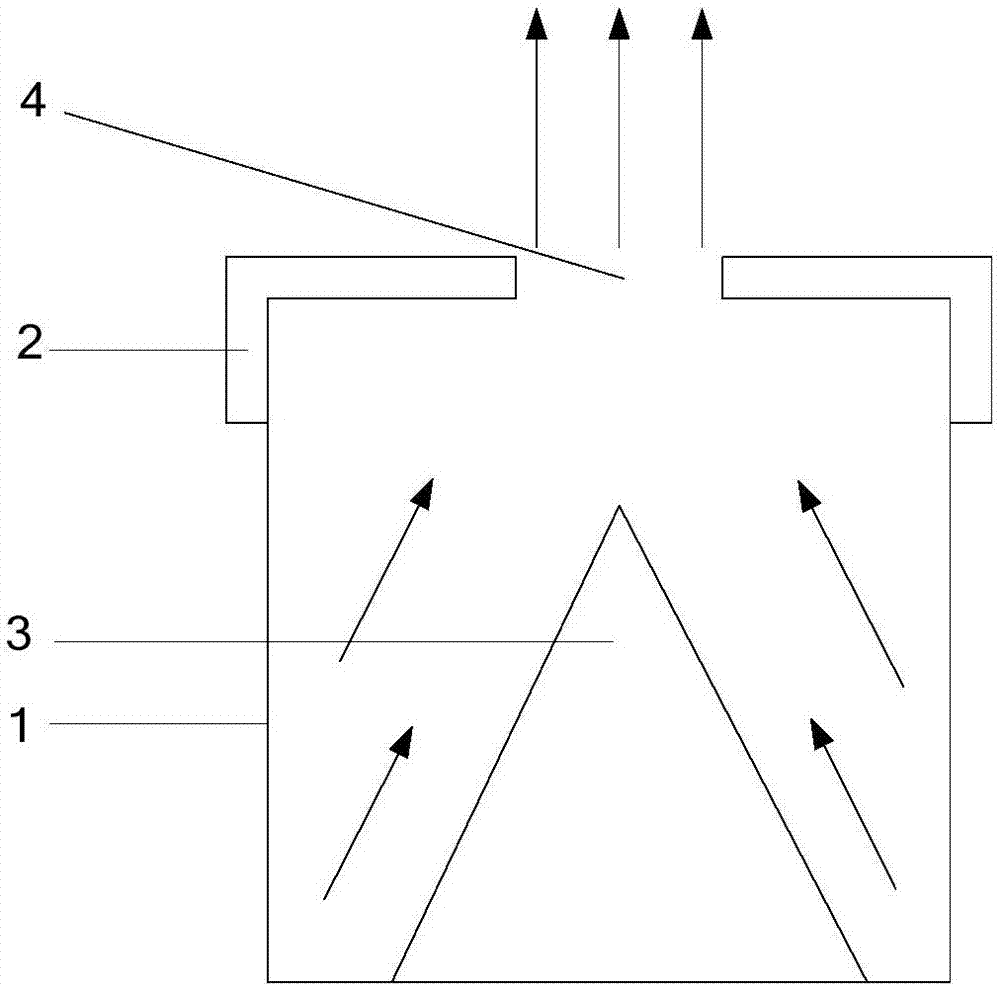

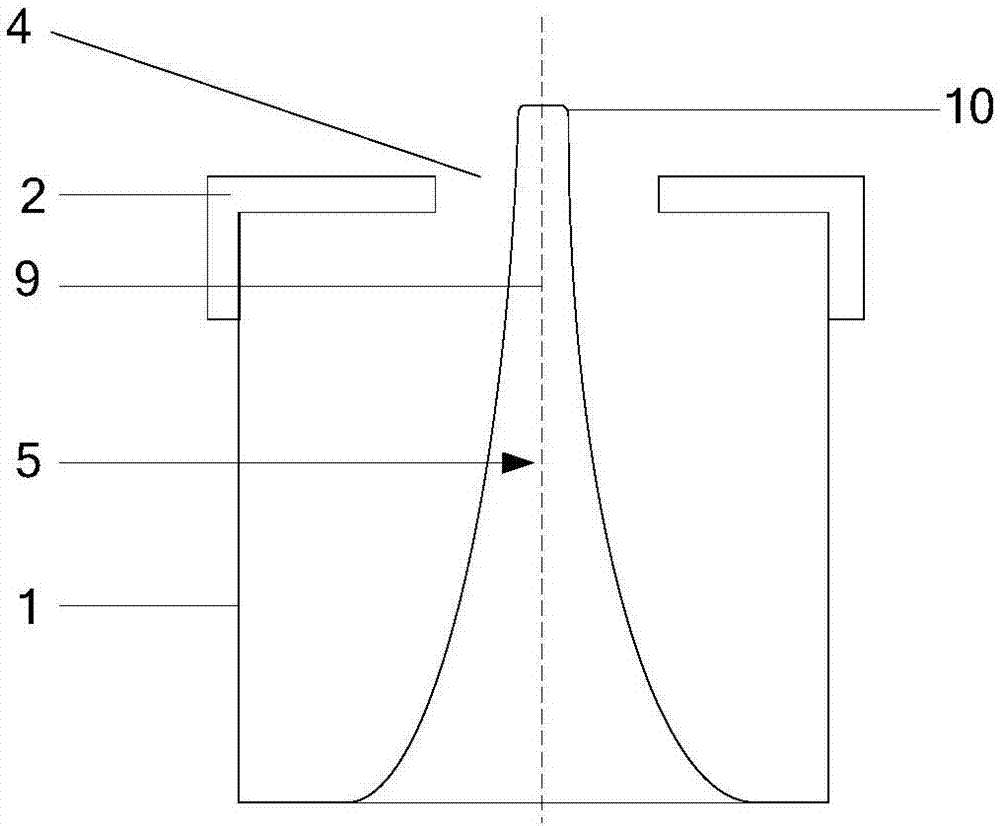

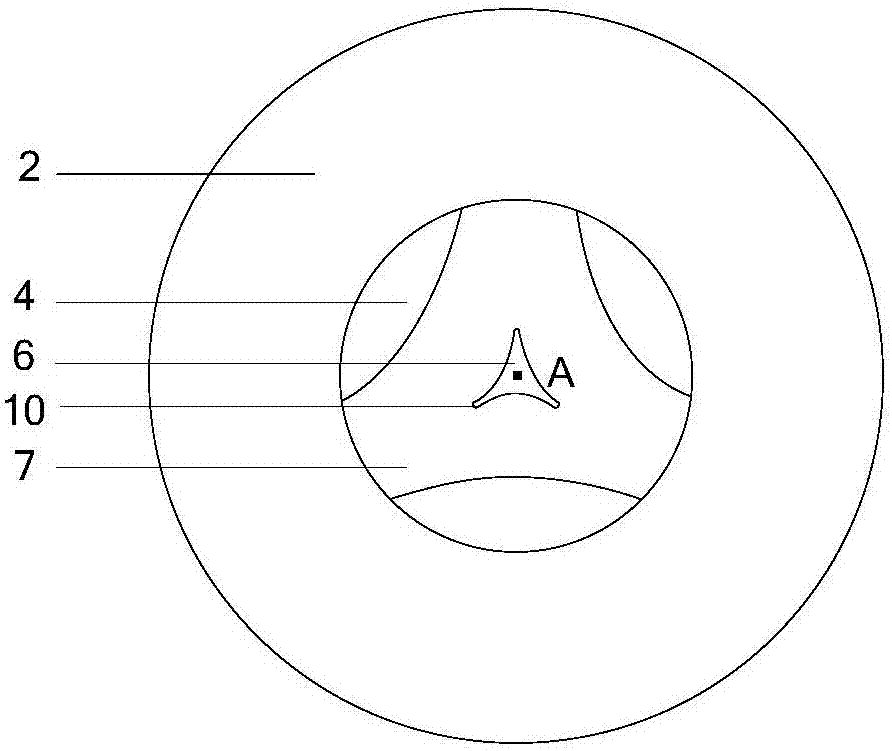

[0031] Embodiment 1 of the present invention provides an evaporation crucible, combined with figure 2 , image 3 and Figure 4 As shown, the evaporation crucible includes a body 1, a cover body 2 and a heat conduction column 5. The body 1 is a hollow chamber for accommodating evaporation materials. Preferably, the shape of the body 1 is a circular truncated or cylindrical, circular truncated or cylindrical The side of the body 1 is an arc surface, which is not easy to adhere to the vapor deposition material. In this embodiment, the shape of the body 1 is a cylinder as an example for illustration. The cover body 2 is arranged on the top of the body 1 , and the cover body 2 has an opening 4 . The heat conduction column 5 is arranged on the bottom wall of the body 1 , and the top end of the heat conduction column 5 is located at the position of the opening 4 . Specifically, the orthographic projection of the top of the heat conduction column 5 on the bottom wall of the body 1 ...

Embodiment 2

[0046] Embodiment 2 of the present invention provides an evaporation equipment, such as Figure 6 As shown, the evaporation equipment includes a heating device 11 and the above-mentioned evaporation crucible, and the heating device 11 is used to heat the evaporation crucible.

[0047] Such as Figure 6 As shown, preferably, the heat conduction column 5 can be integrally formed with the bottom wall of the body 1, that is, the position corresponding to the heat conduction column 5 on the bottom wall of the body 1 is recessed toward the direction of the cover body 2, so that the side wall of the heat conduction column 5 and the The top wall forms an accommodating space 13 . The heating device 11 can be located in the accommodating space 13, and the heating device 11 heats the steamer crucible from the accommodating space 13, that is, from the middle of the body 1, and the heating uniformity is better, which is beneficial to improving the uniformity of evaporation of the evaporat...

Embodiment 3

[0051] Embodiment 3 of the present invention provides a kind of vapor deposition equipment, such as Figure 7 As shown, the difference between the evaporation equipment provided in Example 3 and the evaporation equipment provided in Example 2 is that: the thermal conduction column 5 and the bottom wall of the body 1 do not form an accommodating space 13, and the heating device 11 is located below the evaporation crucible .

[0052] Specifically, such as Figure 7 As shown, the heat conduction column 5 is arranged on the bottom wall of the body 1 and is located inside the evaporation crucible, and the heating device 11 is located below the bottom wall of the body 1 for heating the body 1 .

[0053] It should be noted that, compared with embodiment 2 and embodiment 3, embodiment 2 is a preferred implementation manner. In Example 2, the heating device 11 is located in the accommodating space 13 . Compared with the heating device 11 located below the evaporation crucible in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com