Crystal selection method for accurately controlling single-crystal orientation

A precise control, single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as the inability to precisely control the orientation of single crystal superalloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

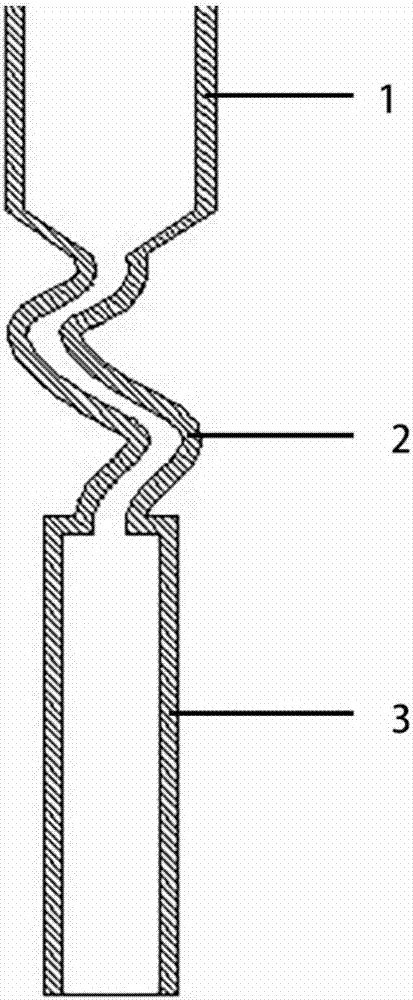

[0021] This example is a method for preparing a single crystal superalloy sample with a primary dendrite orientation deviating from the axial direction by an angle α, and a secondary dendrite orientation deviating from the casting airfoil normal direction by an angle β. In this embodiment, α=0°, β=45°.

[0022] The concrete steps of this embodiment are:

[0023] The first step is to make the mold shell: use wax, use 3D printing to prepare spiral-shaped crystal selection segments, and use molds to prepare cylindrical seed segments and castings. The two ends of the crystal selection section are heated and respectively welded to the seeding section and the casting to obtain a complete wax model. A shell for casting with the same structure as the prior art is obtained by using a standard investment casting shell making process. After the mold shell is completely dewaxed, it is washed with water and dried in a drying oven for later use. The diameter of the seeding segment is 9 m...

Embodiment 2

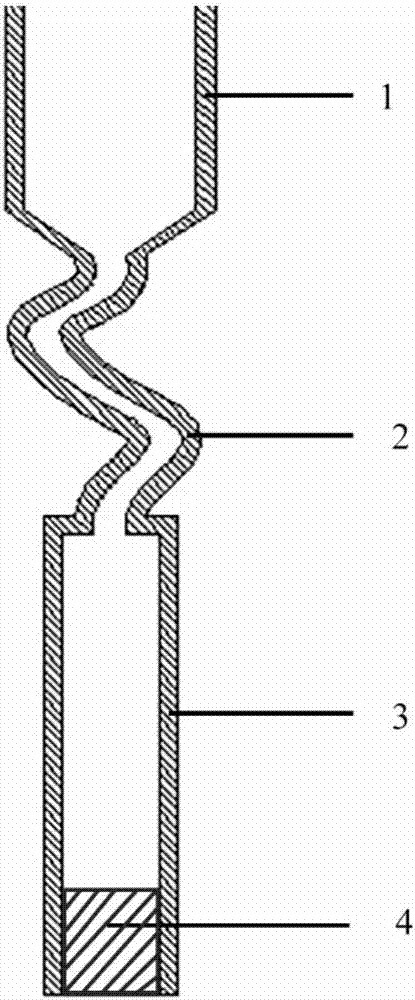

[0027] This example is a method for preparing a single crystal superalloy sample with a primary dendrite orientation deviating from the axial direction by an angle α, and a secondary dendrite orientation deviating from the casting airfoil normal direction by an angle β. In this embodiment, α=3° and β=25°.

[0028] The concrete steps of this embodiment are:

[0029] The first step is to make the mold shell: use wax, use 3D printing to prepare spiral-shaped crystal selection segments, and use molds to prepare cylindrical seed segments and castings. The two ends of the heated crystal selection section are respectively welded to the seeding section and the casting to obtain a complete wax model. A shell for casting with the same structure as the prior art is obtained by using a standard investment casting shell making process. After the mold shell is completely dewaxed, it is washed with water and dried in a drying oven for later use. Among them, the seeding section has a diame...

Embodiment 3

[0033] This example is a method for preparing a single crystal superalloy sample with a primary dendrite orientation deviating from the axial direction by an angle α, and a secondary dendrite orientation deviating from the casting airfoil normal direction by an angle β. In this embodiment, α=5° and β=0°.

[0034] The concrete steps of this embodiment are:

[0035] The first step is to make the mold shell: use wax, use 3D printing to prepare spiral-shaped crystal selection segments, and use molds to prepare cylindrical seed segments and castings. The two ends of the crystal selection section are heated and respectively welded to the seeding section and the casting to obtain a complete wax model. A shell for casting with the same structure as the prior art is obtained by using a standard investment casting shell making process. After the mold shell is completely dewaxed, it is washed with water and dried in a drying oven for later use. The diameter of the seeding segment is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com