Fleece fabric and method for producing it

A technology for pile fabrics and fabrics, applied in the process of manufacturing pile fabrics, and in the field of products made of said fabrics, which can solve the problems of no structural function, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

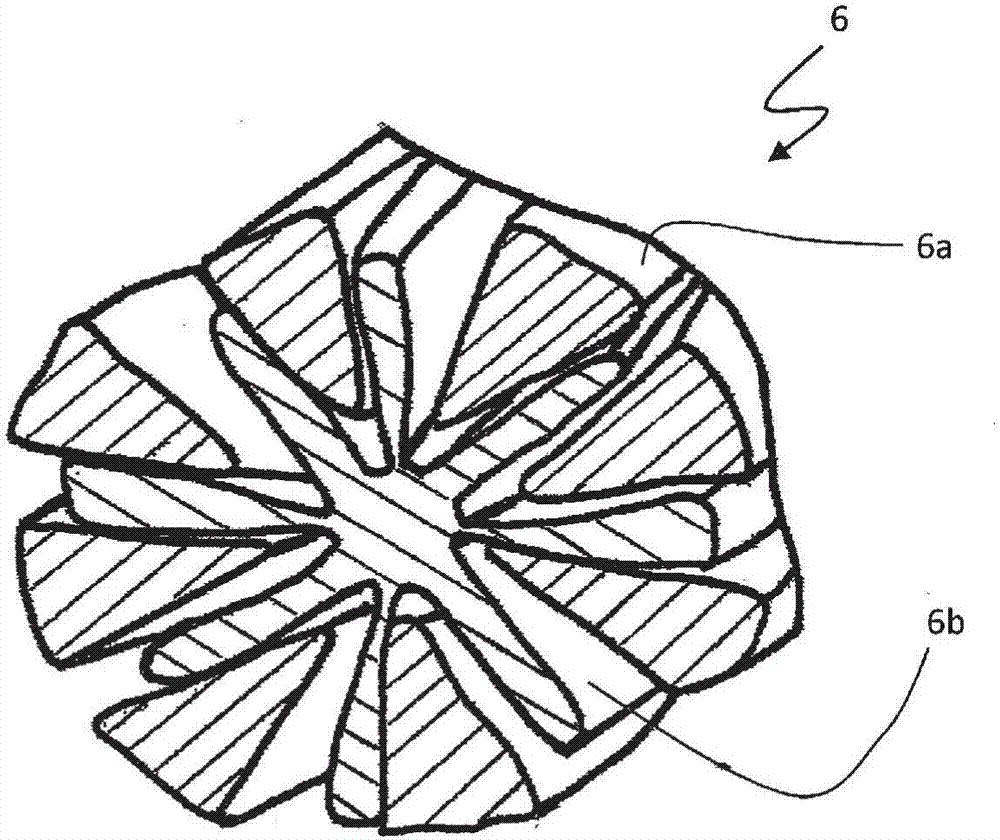

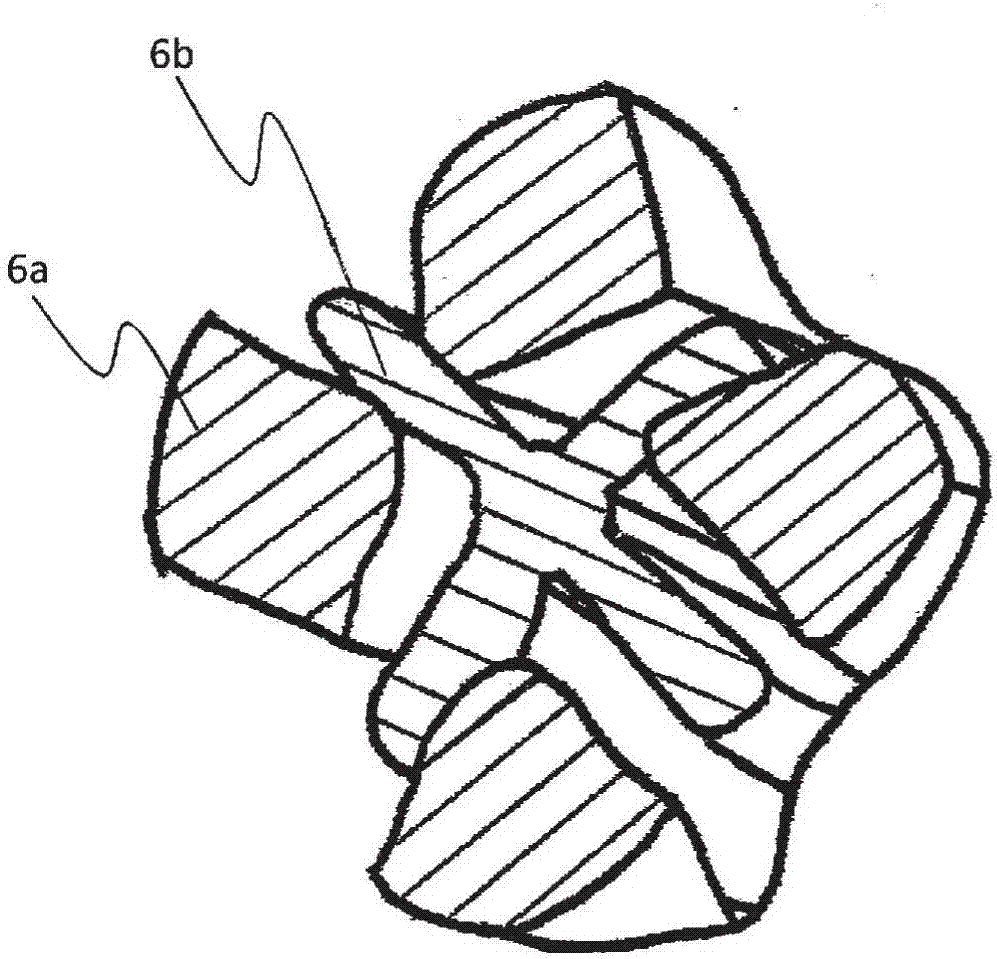

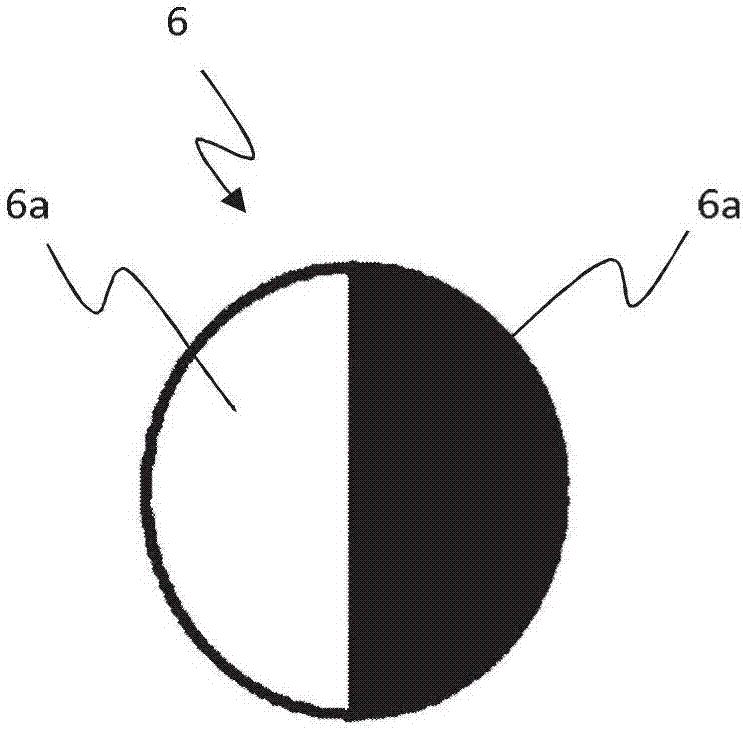

Image

Examples

example 1

[0106] Choose the warp, weft, warp density, weft density, and loom settings according to the values in Table 1. These choices give the resulting fabric a weight of about 10-11 oz / sqyd (335-375 g / cm2). according to Figure 5 Select a weave pattern from the weave report depicted in . Weaving is performed using a dobby type weaving loom with a weft selection system.

[0107] After weaving, the fabric is wetted and stretched lengthwise (warp). As this process occurs, the fabric shrinks across its width (weft) and the elastic yarns pull the weft together. Because the conjugate weft yarns are not elastic, they do not shrink as much as the standard weft yarns used in this example, and the conjugate yarns float on one side of the fabric, forming loops that cover most of the backside of the fabric; all loops Having the same length, the length of the loop is about 4 mm.

[0108] After shrinking, the fabric is subjected to a shrinkproof treatment to reduce shrinkage in further gar...

example 2

[0113] Choose the warp, weft, warp density, weft density, and loom settings according to the values in Table 1. according to Image 6 Select a weave pattern from the weave report depicted in . Examination of the weaving report shows a 1:1 ratio of standard yarn to conjugate yarn, compared to the 1:2 in Example 1. The ratio of the length of the pile 5 to the length of the lower part of the standard yarn is 7 / 3, ie about 2.

[0114] The fabric is used to make an article, namely a pair of skinny jeans with an inner side provided with loops; the jeans are stonewashed after exposing the inner side so as to be abraded during the stonewashing process. At the end of the stonewashing step, the sides of the fabric previously provided with loops are thus covered with pile fabrics of black color due to the color of the sub-filaments of the conjugated yarn, and due to the extremely fine texture obtained by splitting the conjugated filaments The sub-filaments of the number of counts ar...

example 3

[0116] Choose the warp, weft, warp density, weft density, and loom settings according to the values in Table 1. according to Figure 7 Select a weave pattern from the weave report depicted in . According to Example 1, inspection of the weaving report shows that the ratio of standard yarn to conjugate yarn is 1:2. The ratio of the length of the pile 5 to the length of the lower part 3b of the standard yarn is 15 / 6, ie 2.5. Furthermore, the upper part of the standard yarn floats over two warp yarns, while the connecting part 7 of the conjugated yarn 2 floats over one warp yarn, said connecting part 7 being an adjacent warp yarn.

[0117] The fabric is used to make articles, namely jackets in which the fleece has an inner side provided with loops; the jacket is stonewashed after exposing the inner side so as to be abraded during the stonewashing process. At the end of the stone-washing step, the sides of the fabric previously provided with loops are covered with pile fabrics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com