Load box having automatic internal state induction function and used for pile foundation self-balance tests

An automatic sensing and internal state technology, applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems of easy misjudgment of test pile quality in the measurement system, test failure, damage of displacement rod, etc., and achieve simple and effective high-pressure sealing , Simplify the installation process and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

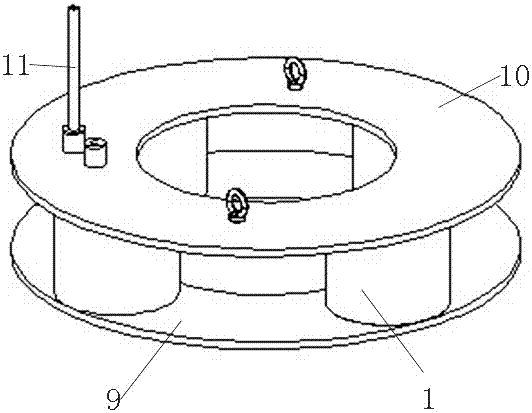

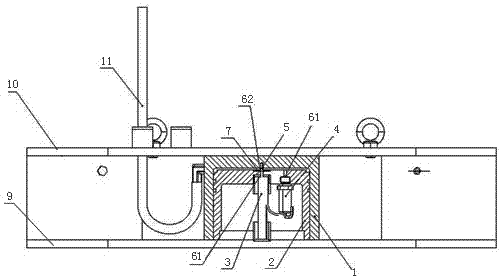

[0031] Embodiment one: if Figure 1-5 shown.

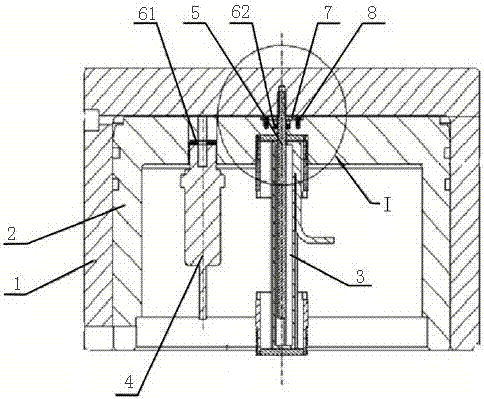

[0032] The load box of the present embodiment is a combined load box, and the combined load box includes a base plate 9, a panel 10, several series-connected oil cylinders 1 arranged between the base plate 9 and the panel 10, the displacement sensor 3 and the oil pressure The sensors 4 are all arranged inside the piston of the oil cylinder 1 .

[0033] In this embodiment, the end of the displacement rod 5 of the displacement sensor 3 passes through the piston 2 and is inserted into the bottom of the oil cylinder 1 fixedly without penetrating, and the oil pressure sensor 4 is connected to the bottom of the piston 2 through threads. The displacement rod 5 of the displacement sensor 3 is screwed to the bottom of the oil cylinder 1 .

[0034] The outer cover of the displacement rod 5 is equipped with an O-ring 61, and a Y-ring 62 embedded in the piston 2 is also provided. The Y-ring 62 is provided with a sealing ring baffle 7, and t...

Embodiment 2

[0039] Embodiment two: see attached Figure 6 .

[0040] The load box of this embodiment is still a combined load box, and the similarities with Embodiment 1 will not be repeated. The difference is that in this embodiment, the end of the displacement rod 5 of the displacement sensor 4 passes through the piston and directly Going through the bottom of the oil cylinder, the displacement rod 5 is threadedly connected to the bottom of the oil cylinder and is provided with a threaded plug outside. The displacement rod 5 is covered with an O-shaped sealing ring 61 and a Y-shaped sealing ring 62 .

Embodiment 3

[0041] Embodiment three: see attached Figure 7 .

[0042] The load box of this embodiment is still a combined load box, and the similarities with Embodiment 1 will not be described in detail. The difference is that the displacement sensor is installed externally, and is arranged on the jack cylinder between the bottom plate 9 and the panel 10. Externally, the oil pressure sensor is installed at the oil outlet of the jack, and then sealed and protected with a sealing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com