Large true tri-axial physical model test method for researching thin interbed fracturing fracture extension principle

A test method and technology of thin interlayers, applied in the direction of earthwork drilling, production fluids, wellbore/well components, etc., which can solve the problem that horizontal two-way stress cannot be layered, cannot apply separate two-way stress in thin interlayers, and cannot. Research on the law of crack propagation in thin interbedded layers, etc., to achieve the effect of improving the development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

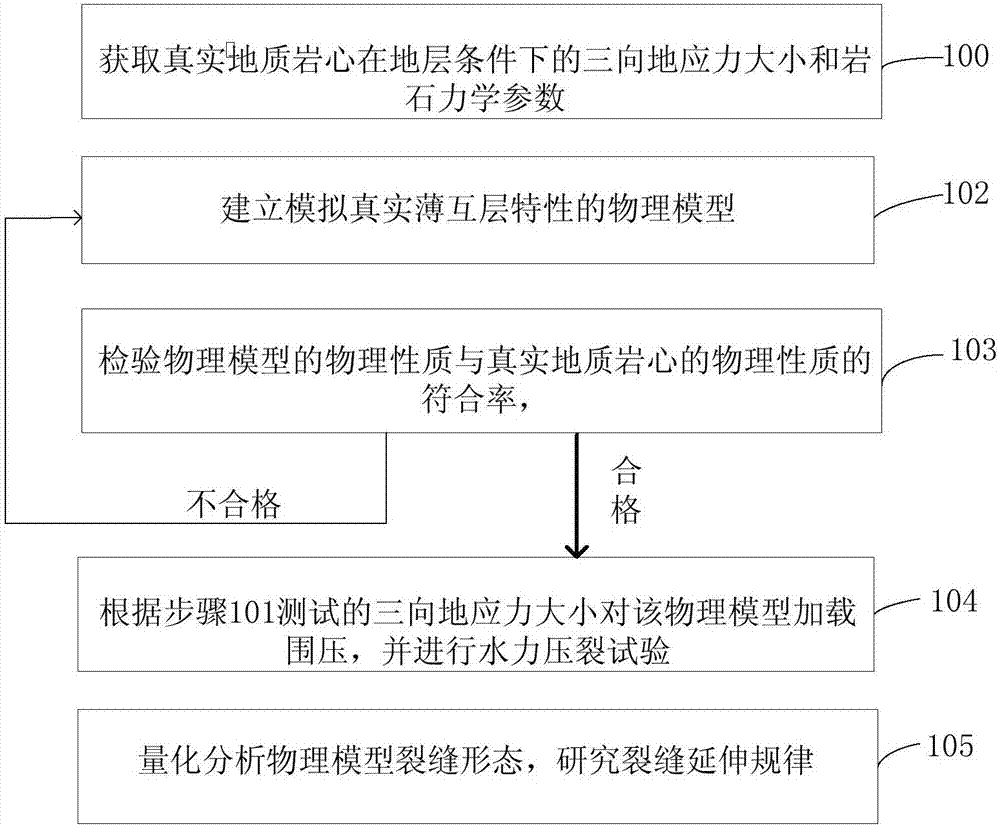

[0027] Such as figure 1 As shown, a large-scale true triaxial phantom test method for studying the extension law of thin interlayer fracturing cracks provided by the embodiment of the present invention includes the following steps:

[0028] Step 101, obtaining the three-dimensional in-situ stress and rock mechanics parameters of the real geological core under formation conditions;

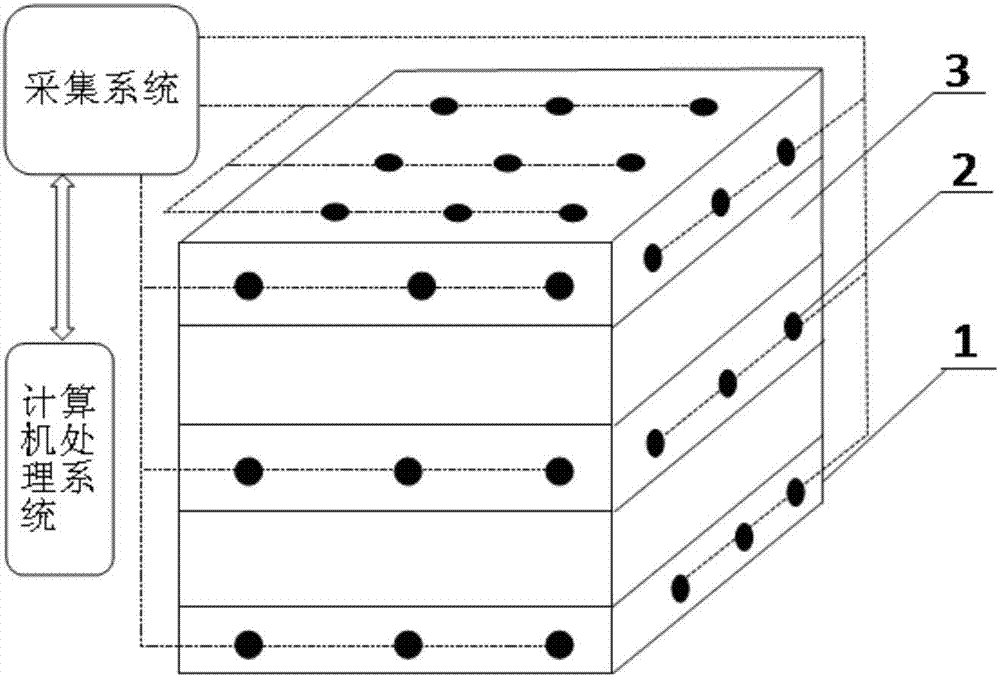

[0029] Step 102, establishing a physical model 1 for simulating a real thin interlayer;

[0030] Step 103, checking the coincidence rate of the physical parameters of the physical model 1 and the physical parameters of the real geological core, if the coincidence rate is qualified, then proceed to step 104; if the coincidence rate is not qualified, then repeat step 102 until the coincidence rate is qualified;

[0031] Step 104, load confining pressure on the physical model 1 according to the three-dimensional ground stress tested in step 101, and perform a hydraulic fracturing test;

[0032] Step...

Embodiment 2

[0035] On the basis of Embodiment 1, in the step 101, the method for obtaining the real geological core is an existing method, which will not be described in detail again.

[0036] The real geological core is a full-diameter core. Full-diameter cores refer to cores taken from oil (gas) layers by coring technology, without cutting and splitting, and the entire section is used for laboratory analysis to determine relevant parameters of the columnar core.

[0037] The shape of the real geological core is a cylinder with a height of 50mm and a diameter of 25mm, and the shape of this size is adopted to adapt to the shape of the triaxial compression test machine. The triaxial compression testing machine is a device used to test the three-dimensional in-situ stress and rock mechanics parameters of real geological cores under formation conditions. The triaxial compression testing machine is an existing device and will not be described here. Among them, rock mechanics parameters inclu...

Embodiment 3

[0044] On the basis of Example 1, the process of checking the physical model 1 is carried out indoors. Specifically, the model rock core is obtained by drilling on the physical model 1, and the physical parameters of the model rock core are tested. After the test, the physical parameters of the model rock core are compared. The coincidence rate of the physical parameters and the physical parameters of the real geological core, if the coincidence rate is greater than or equal to 95%, it is qualified, then proceed to step 104; if the coincidence rate is less than 95%, it is unqualified, then repeat step 102 until the coincidence rate qualified.

[0045] Among them, the physical parameters to be tested for the model core include Young's modulus and Poisson's ratio, and the testing methods are existing methods, which will not be described in detail here.

[0046] Wherein, in step 103, one model core needs to be obtained on each thin interbed 3, and each model core is tested, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com