Anti-leakage double-surface pulling rivet and double-surface tight connecting method

A rivet, double-sided technology, applied to rivets, engine seals, engine components, etc., can solve the problems of dripping, leakage, and insufficient leakage prevention of rivet seals, and achieve the effect of improving corrosion resistance and attenuating vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

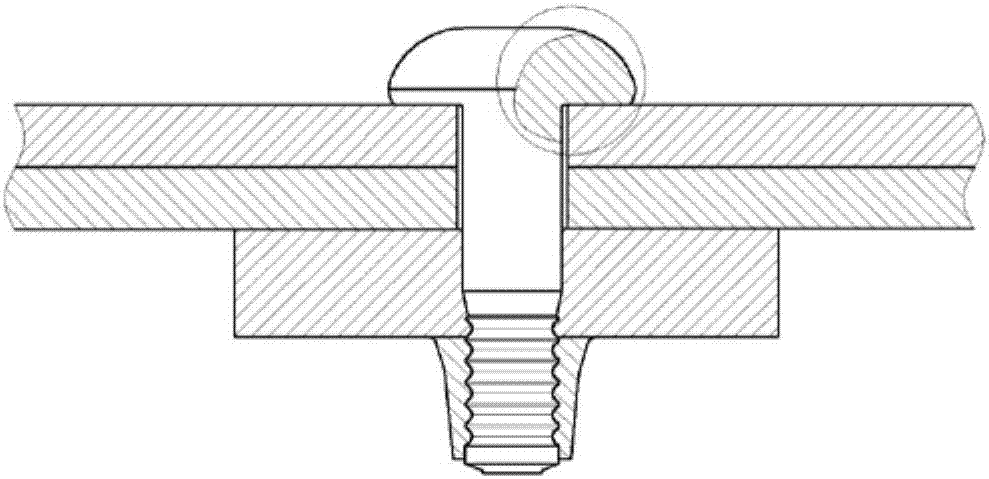

[0048] Such as Figure 2-5 12, a leak-proof double-sided pull rivet of the present invention comprises a rivet 1, a collar 2 and a sealing ring 3, the rivet 1 is composed of a rivet head 4 and a rivet rod 5, and the pull rivet 5 and the rivet head The integral molding structure is adopted, and the inner end surface of the rivet head 4 is provided with a ring-shaped groove 6 around the rivet rod 5, and the sealing ring 3 is arranged in the ring-shaped groove 6 to play a role of connection and sealing when the connection is fastened. The collar 2 The riveted part 11 is fastened and connected by the rivet 1 sleeved on the riveting rod 5 . The collar structure adopts the existing collar structure.

[0049] The riveting rod 5 is successively divided into a polished rod 7, a locking groove section 8, a breaking groove section 9 and a tail pulling groove section 10 from the connecting end with the rivet cap head 4.

[0050] The polished rod section 7 is a polished rod structure for...

Embodiment 2

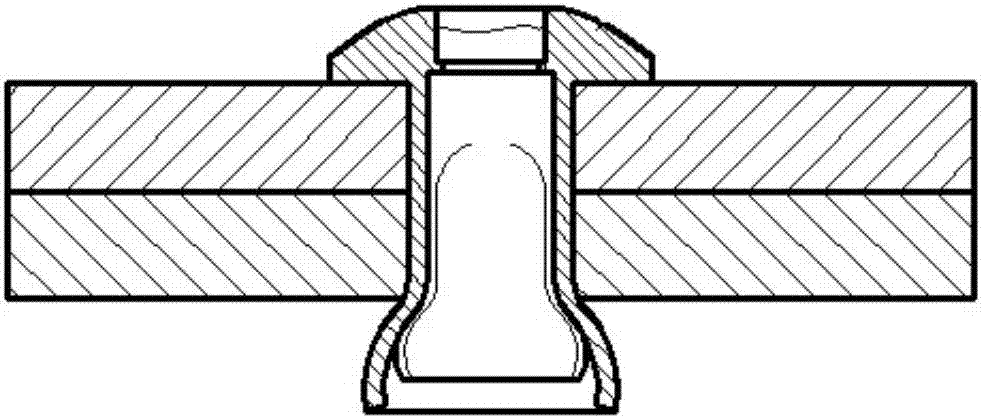

[0053] Such as Figure 6 , 6-1 , 8, 8-1, 9, 9-1, and 13, a leak-proof double-sided pull rivet of the present invention, on the basis of Embodiment 1, the inner ring wall of the annular groove (6) There is a transition step between (16) and the outer circle of the polished rod section (7). The transition step is generally 0.4mm-4mm. By leaving a ring-shaped platform on the inner end surface of the rivet cap head 4 between the ring surface of the inner ring wall of the ring groove 6 and the ring surface of the polished rod section, it is mainly used for parts with higher leak-proof and waterproof requirements. , Avoid direct contact of the sealing ring with the edge of the riveting hole, reduce the shear fatigue effect of the edge of the riveting hole (acute angle) on the sealing ring, reduce the risk of the sealing ring being damaged, and improve the service life.

[0054] When the riveted product has relatively higher leak-proof requirements, using the riveting of the prese...

Embodiment 3

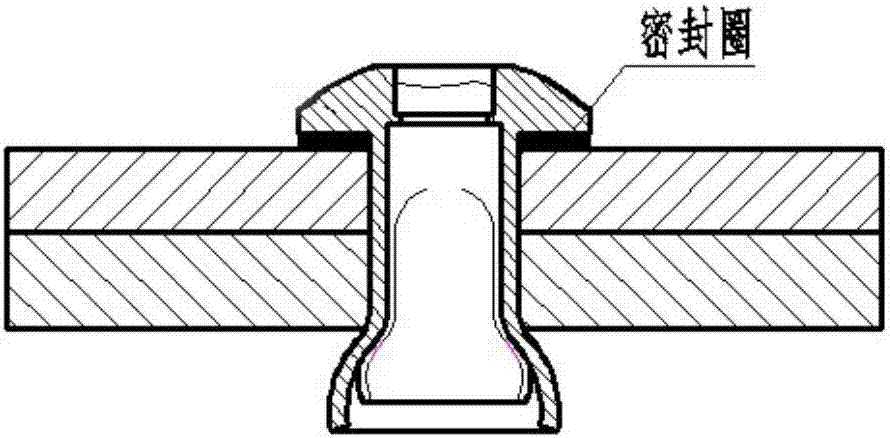

[0061] Such as Figure 7 , 7-1 , 10, 11, and 14, a leak-proof double-sided pull rivet of the present invention, on the basis of Embodiment 1, the inner ring wall of the annular groove 6 is smoothly connected with the outer circular surface of the polished rod section 7, and the annular groove 6 The angle between the wall surface of the outer ring and the inner end surface of the rivet cap head 4 is rounded. When the matching gap between the riveting rod 5 and the riveting hole 12 was relatively large, there was no need to stay an annular platform between the inner wall surface of the annular groove 6 and the outer circular surface of the polished rod section 7, and the inner wall surface of the annular groove 6 and the outer surface of the polished rod section 7 The outer circular surface of the polished rod section 7 is smoothly connected. When the sealing ring 3 is squeezed, the inner edge of the sealing ring 3 will be squeezed into the gap to play a sealing role. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com