Clutch hydraulic oil circuit structure, clutch structure, driving device and method

A technology of hydraulic oil circuit and clutch, applied in the direction of clutch, transmission device, gear transmission device, etc., can solve the problems of increasing the use and maintenance cost of the rack car, reducing the service life of the bearing bush and ring parts, and the damage of the bearing bush and ring parts. , to achieve the effect of reducing maintenance costs, low costs, and ensuring smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The "upper end" and "top end" in the present invention refer to the end close to the shell; "lower end" and "bottom end" are vice versa.

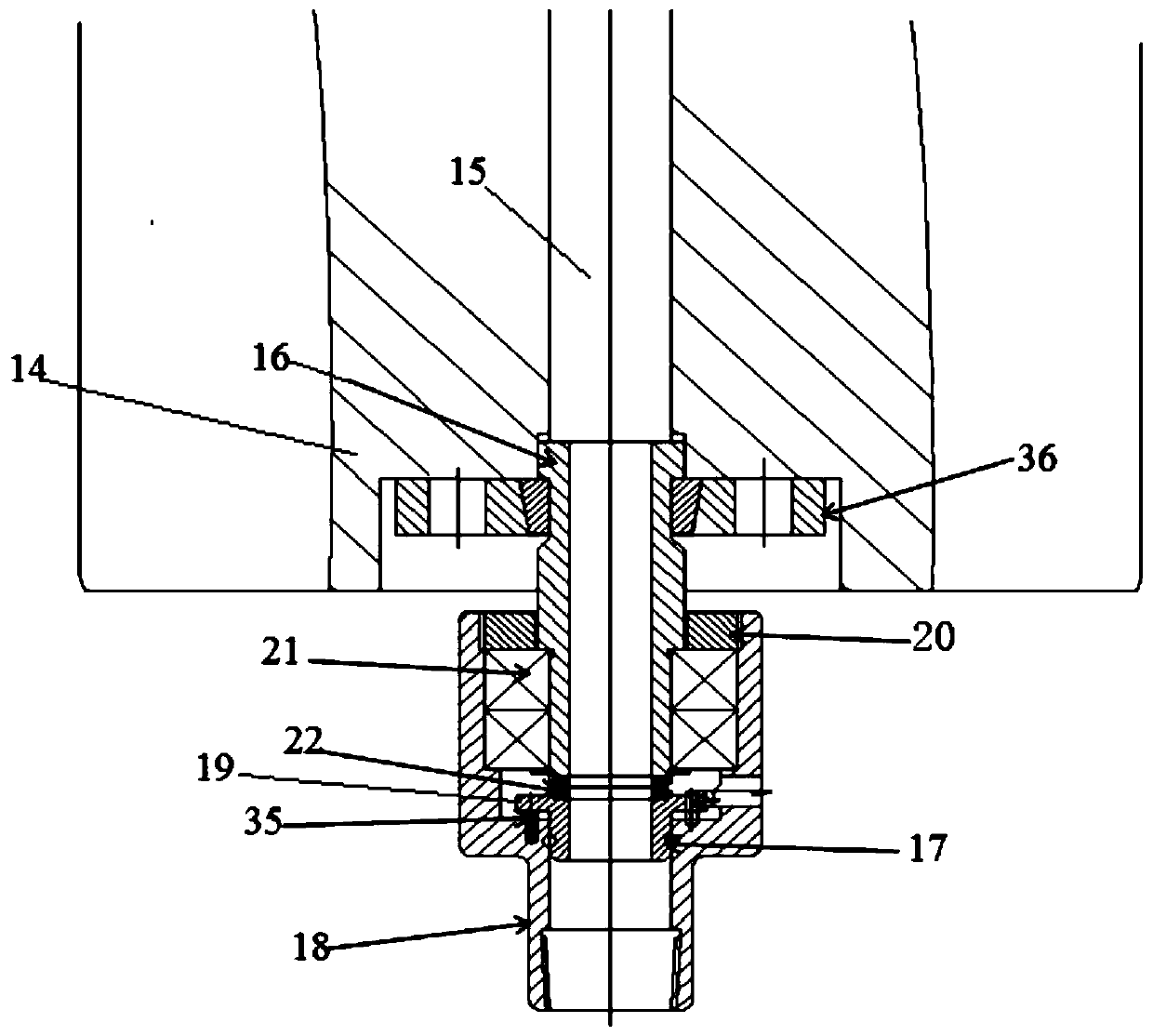

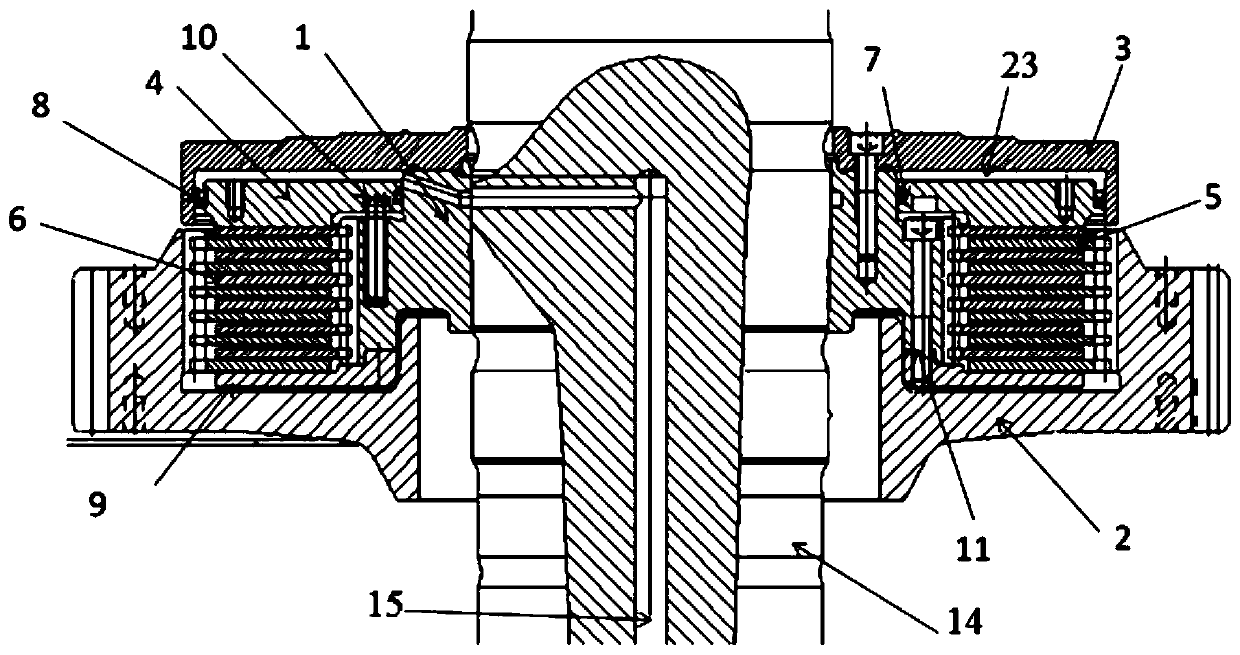

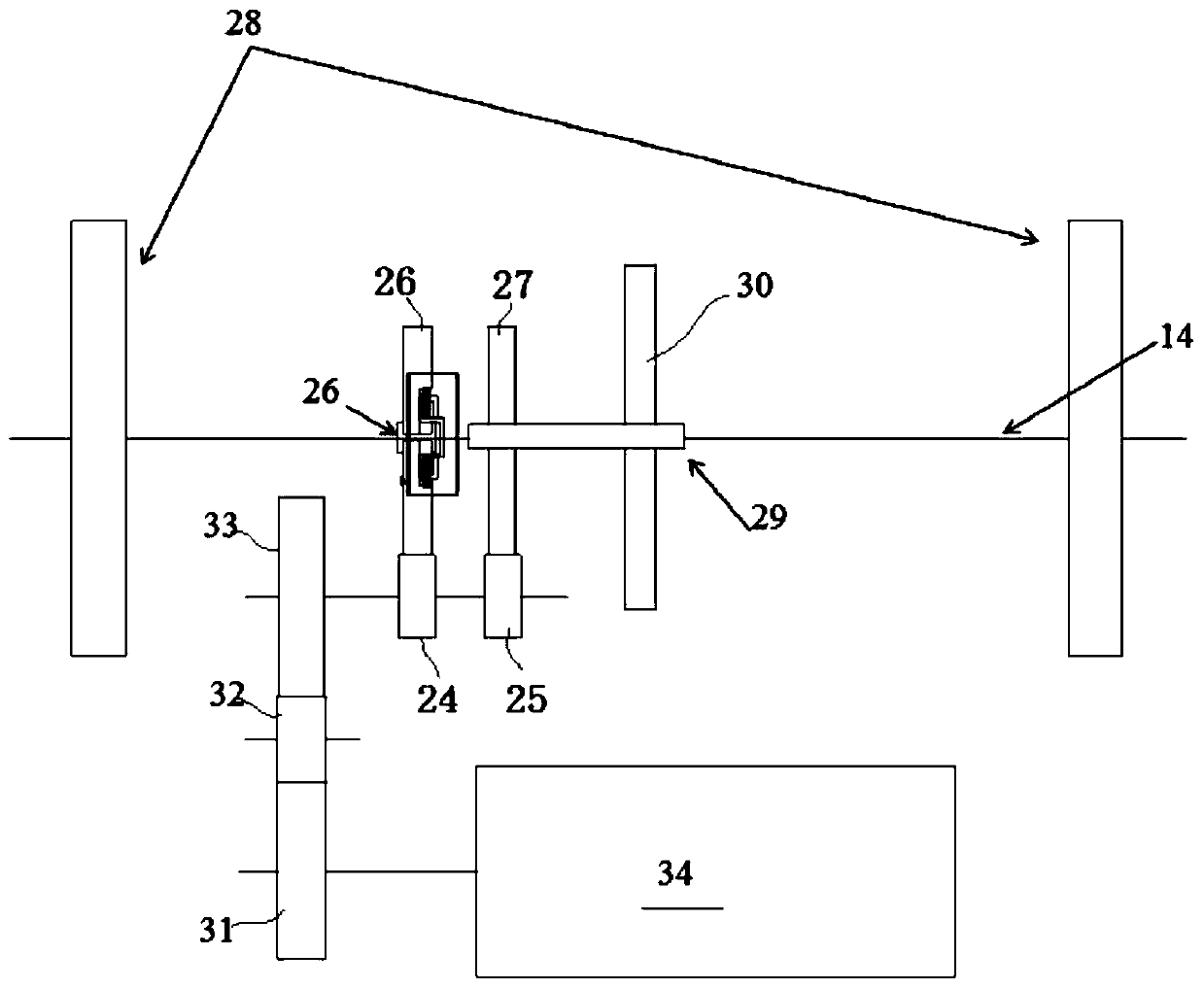

[0024] like figure 1 As shown, the hydraulic oil circuit structure includes an oil channel 15 arranged in the axle 14; one end of a first inner tube 16 communicating with the inlet end of the oil channel 15 is installed on the axle 14 with an interference fit, and can be The axle 14 rotates; the other end of the inner tube 16 communicates with the second inner tube 17 ; the second inner tube 17 is fixedly connected to the inner wall of the nozzle nozzle 18 .

[0025] The bottom end of the second inner tube 17 is pressed into the oil nozzle nozzle 18 with an interference fit; the top side wall of the second inner tube 17 is provided with a protrusion 19; Elastic connection.

[0026] The inner diameter of the upper end of the oil nozzle nozzle 18 is larger than the inner diameter of the lower end of the oil nozzle nozzle 18; There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com