Hydraulic type yellow oil injection machine and use method

A butter filling, hydraulic technology, applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of high labor intensity, slow filling speed, unsafe, etc., to improve the heat conduction effect, improve the safety factor, The effect of increasing the injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

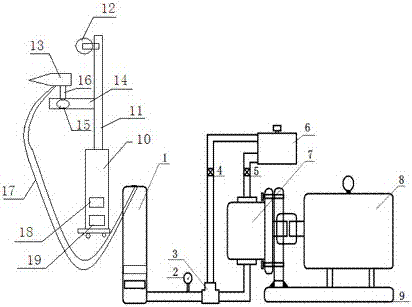

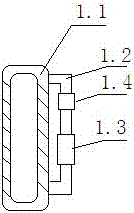

[0019] The present invention includes an oil storage barrel 1, a pressure gauge 2, a pressure regulating valve 3, a first gate 4, a second gate 5, a fuel tank 6, a gear pump 7, a motor 8, a motor seat 9, a hydraulic device 10, a hydraulic rod 11, and a camera 12. Oil filling nozzle 13, support platform 14, micro motor 15, support shaft 16, oil inlet pipe 17, gear pump 7 and motor 8 are fixed on the motor base 9, and the output shaft of motor 8 is connected to gear pump 7, gear pump 7 The output end of the oil tank 6 is connected to the oil tank 6 through the second gate 5, and the outlet end of the oil tank 6 is connected to the oil storage barrel 1 through the first gate 4, the pressure regulating valve 3 and the pressure gauge 2, and the oil storage barrel 1 is connected to the fuel tank 1 through the oil inlet pipe 17. Greasing nozzle 13, said fueling nozzle 13 is fixed on the supporting rotating lifting mechanism, supporting rotating mechanism comprises hydraulic device 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com