Gravel material moisture content on-line automatic detection instrument

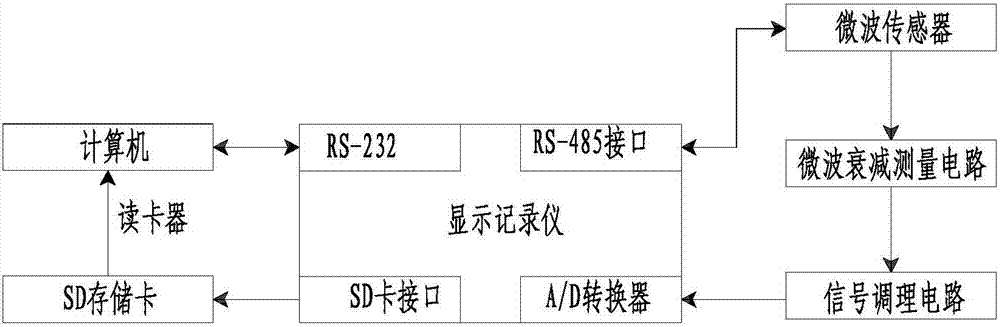

A sand and gravel material and detector technology, which is applied in the field of sand and gravel material detection, can solve the problems of complex structure, limited capacitance method to measure moisture content, etc., and achieve strong anti-interference ability, no risk of excessive radiation, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

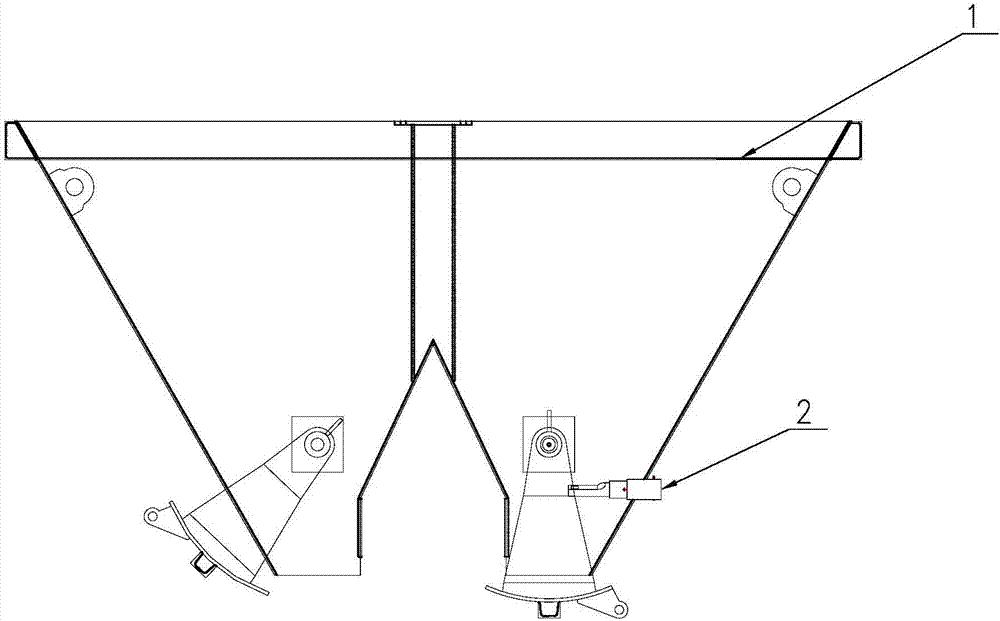

[0030] Such as Figure 1-2 As shown, an online automatic detector for the moisture content of sand and gravel in a silo, including a sand and gravel silo 1 and a detector 2;

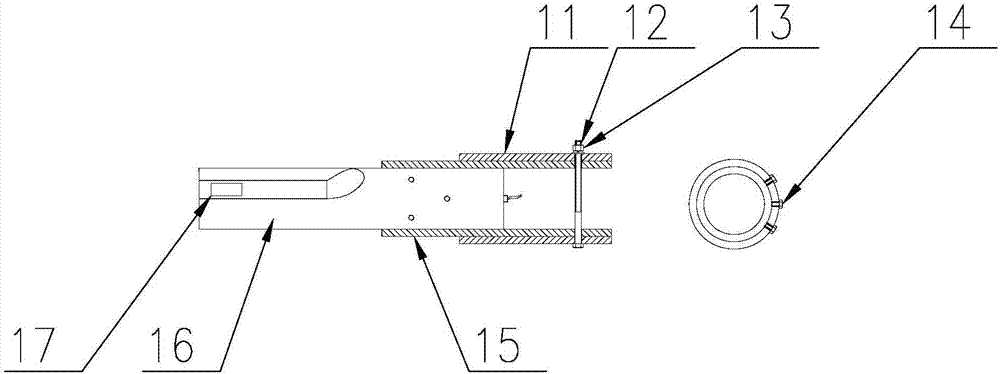

[0031] The detector 2 includes a casing 11, a bolt 12, a nut 13, a set screw 14, a mounting pipe 15, a sensor 16, and a ceramic panel 17;

[0032] The silo wall of the sand and gravel silo 1 is provided with an installation opening, the casing 11 passes through the installation opening, and the side wall of the casing 11 is welded and fixed to the inner peripheral wall of the installation opening; the installation pipe 15 is penetrated in the casing 11, and Three setscrews 14 arranged circumferentially along the side wall of the casing 11 abut against the outer wall of the installation pipe 15; Connect with the nut 13 to fix the casing 11 and the installation pipe 15 after passing through the relief hole;

[0033] The sensor 16 is arranged in the casing 11, and its front end is exposed to the sand and ...

Embodiment 2

[0039] Such as Figure 4 As shown, an online automatic detector for moisture content of a gravel material conveying belt conveyor, comprising a gravel material conveying belt conveyor 4, a detector 2, and a belt conveyor detector mounting frame 3;

[0040] The detector includes bushing 11, bolt 12, nut 13, set screw 14, installation tube 15, sensor 16, ceramic panel 17; belt conveyor detector mounting frame 3 includes bending piece 31, mounting plate 32;

[0041] The bending piece 31 is two U-shaped plates placed opposite to each other, and the opening ends of the U-shaped plates are placed facing each other; the mounting plate 32 is placed above the bending piece, and the two ends of the lower surface are against the side wall of the bending piece 31 Welding; the other side wall of the bending part 31 is fixedly connected with the gravel material conveying belt conveyor 4 by bolts;

[0042]The surface of the sleeve 11 is provided with an installation opening along the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com