A remote control and diagnosis system and method for a bipolar plate preparation hot press

A technology of remote control and diagnosis system, applied in general control system, control/regulation system, test/monitoring control system, etc., can solve the problem of difficult to achieve precise control of bipolar plate preparation hot press, low factory production efficiency, and complex faults. To ensure the accuracy of fault diagnosis and diagnosis, solve the difficulty of knowledge acquisition, and achieve the effect of high fault diagnosis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

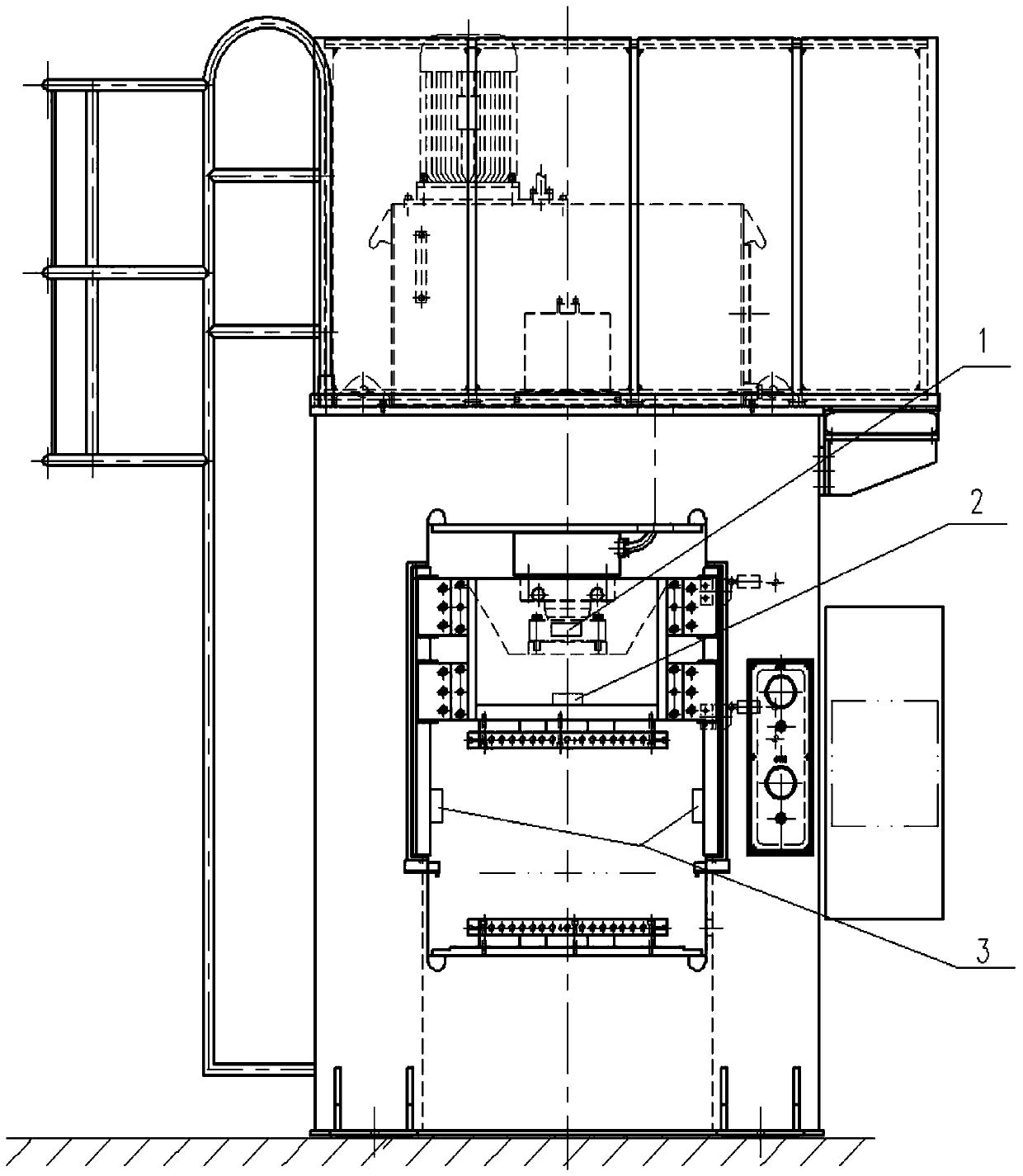

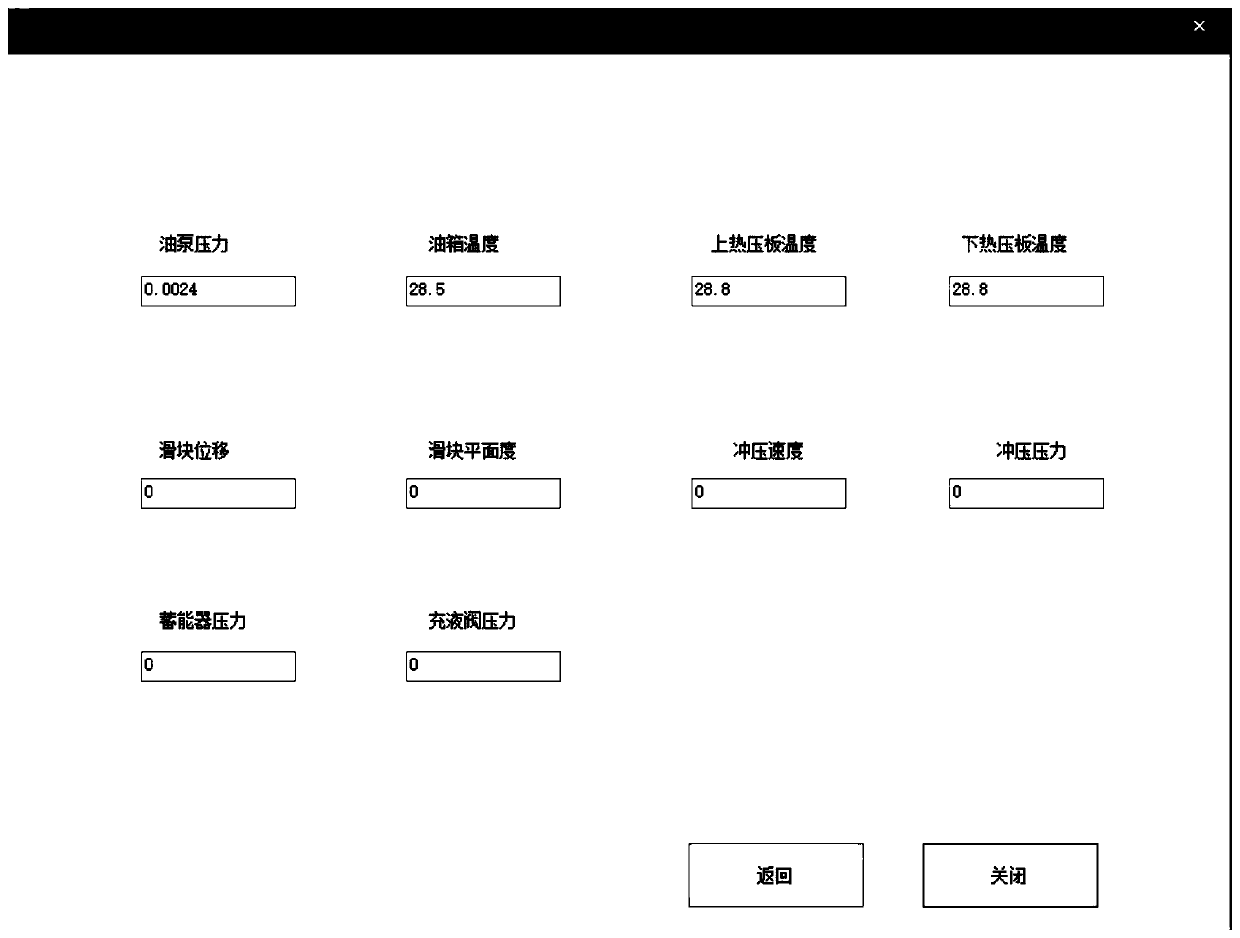

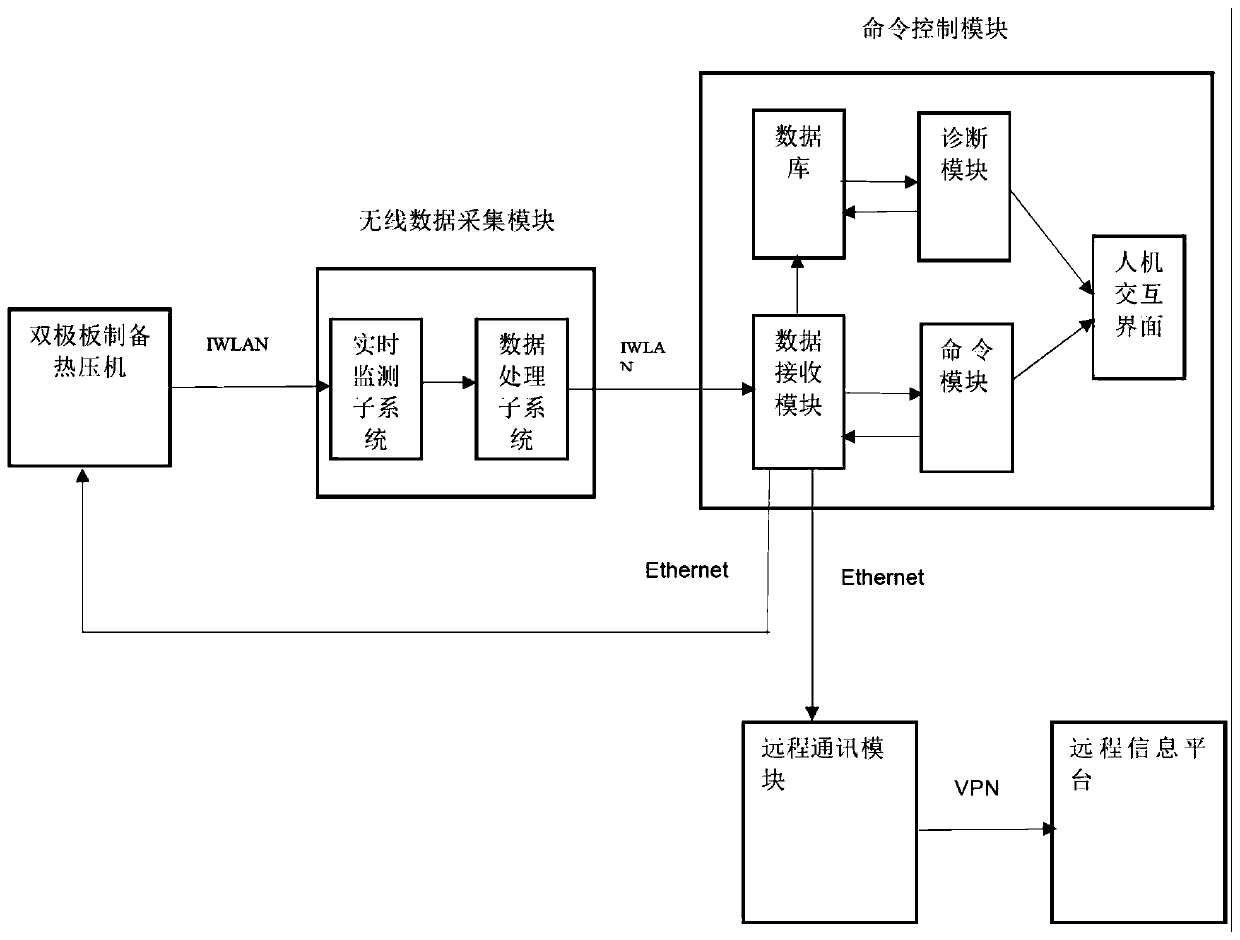

[0062] Such as figure 1 Part of the sensor layout of the wireless data acquisition module of the remote control and diagnostic system for the bipolar plate preparation hot press. 1 is an acceleration wireless sensor, 2 is an inclination wireless sensor, and 3 is a wireless infrared temperature sensor. Since the working temperature of the hot pressing plate of the bipolar plate preparation hot press is not lower than 160°C, it is difficult for the traditional circuit to work in this working environment. Therefore, wireless sensors are used to establish a wireless local area network to realize wireless monitoring. The remote communication module communicates with the command control module via Ethernet. The command control module has multiple network interfaces to realize data intercommunication between the wireless data acquisition module, the remote communication module and the command control module. The communication mode of each module of the present invention meets the ...

Embodiment 2

[0067] The bipolar plate preparation hot press is a complex large-scale equipment coupled with mechanical, electrical, and hydraulic systems, and its faults have obvious nonlinearity and coupling. Therefore, for the fault diagnosis of the bipolar plate preparation hot press, a reasonable fault monitoring should be established first. Point and establish a reasonable state range of monitoring point data for the working process of the bipolar plate preparation hot press. It is only the most basic function to judge whether the bipolar plate preparation hot press is faulty by analyzing the signals measured at the monitoring points. Due to the complexity of the bipolar plate preparation hot press, there are many monitoring points. According to the nonlinear relationship between the monitoring points, the specific cause of the failure of the bipolar plate preparation hot press can be found.

[0068] The remote fault diagnosis system for hot press machine for bipolar plate preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com