Method of using unmanned plane with electromagnetic sucker to implement on/off line of inspection robot

A line inspection robot and electromagnetic sucker technology, applied in the field of robotics, can solve problems such as power outage operations, economic losses, and difficulty in reaching aerial ladder vehicles, and achieve the effect of improving line inspection efficiency and safety, and quick separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

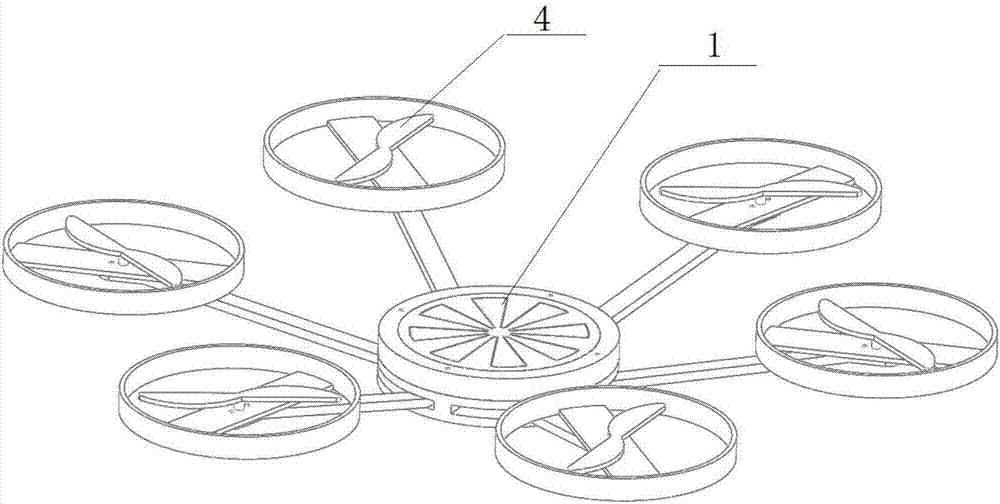

[0033] figure 2 It is a structural schematic diagram of an unmanned aerial vehicle with an electromagnetic chuck of the present invention. Such as figure 2 As shown, a UAV 5 with an electromagnetic chuck provided by the present invention includes a body in which a central processing unit is disposed, and a plurality of arms are connected to the body, and each arm is connected to a rotor 4 .

[0034] The drone also includes: an electromagnetic chuck 1, which is installed on the body and keeps the drone balanced; the electromagnetic chuck 1 is connected to a control circuit, and the control circuit is taken from the rotor drone. Electricity and control the power on or off of the electromagnetic chuck, and then generate or eliminate the magnetic field.

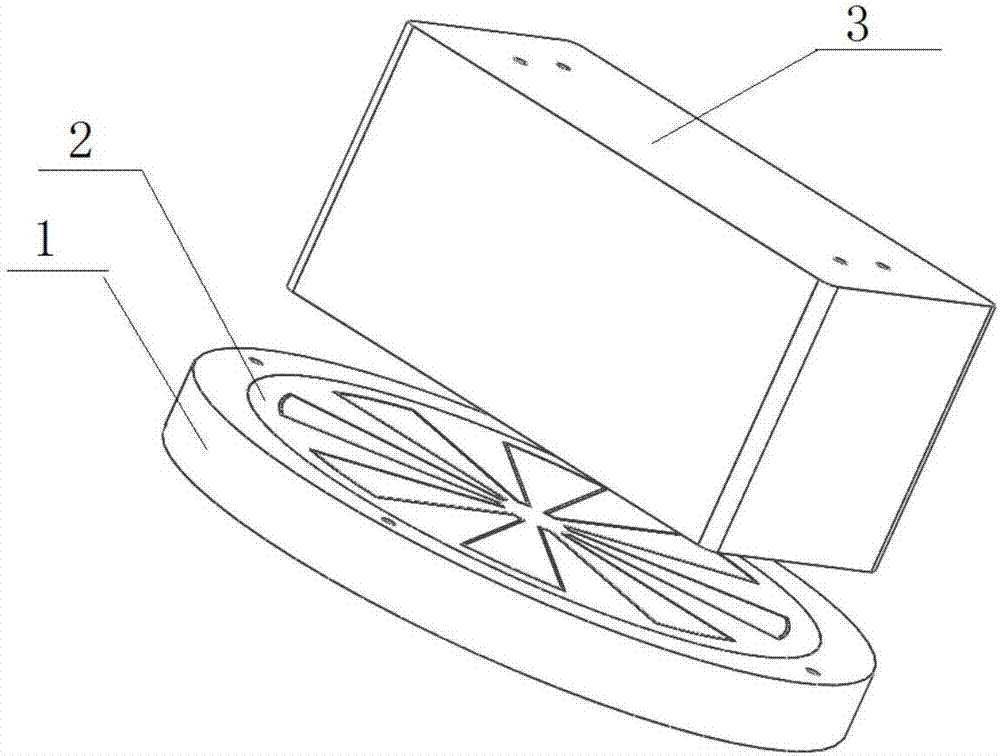

[0035] figure 1 It is a schematic structural diagram of the electromagnetic chuck of the drone of the present invention, as shown in the figure, the electromagnetic chuck 1 of the drone includes a coil, the coil is connected...

Embodiment 2

[0050] The present invention also provides a figure 2 The working method of the drone with magnetic chuck shown.

[0051] The working method of the UAV with the electromagnetic chuck of the present invention includes two working states, namely the power-on state and the power-off state.

[0052] Wherein, in the energized state, the control circuit controls the electromagnetic chuck to generate a magnetic field, so that the electromagnetic chuck can absorb the magnetic element;

[0053] In the power-off state, the control circuit controls the electromagnetic chuck to be energized to eliminate the magnetic field, so that the electromagnetic chuck is separated from the magnetic element.

[0054] Further, the method also includes the distance sensor detecting the degree of attraction between the electromagnetic chuck and the magnetic element being attracted and sending the result to the central processing unit, which then sends the result to the monitoring terminal for real-time...

Embodiment 3

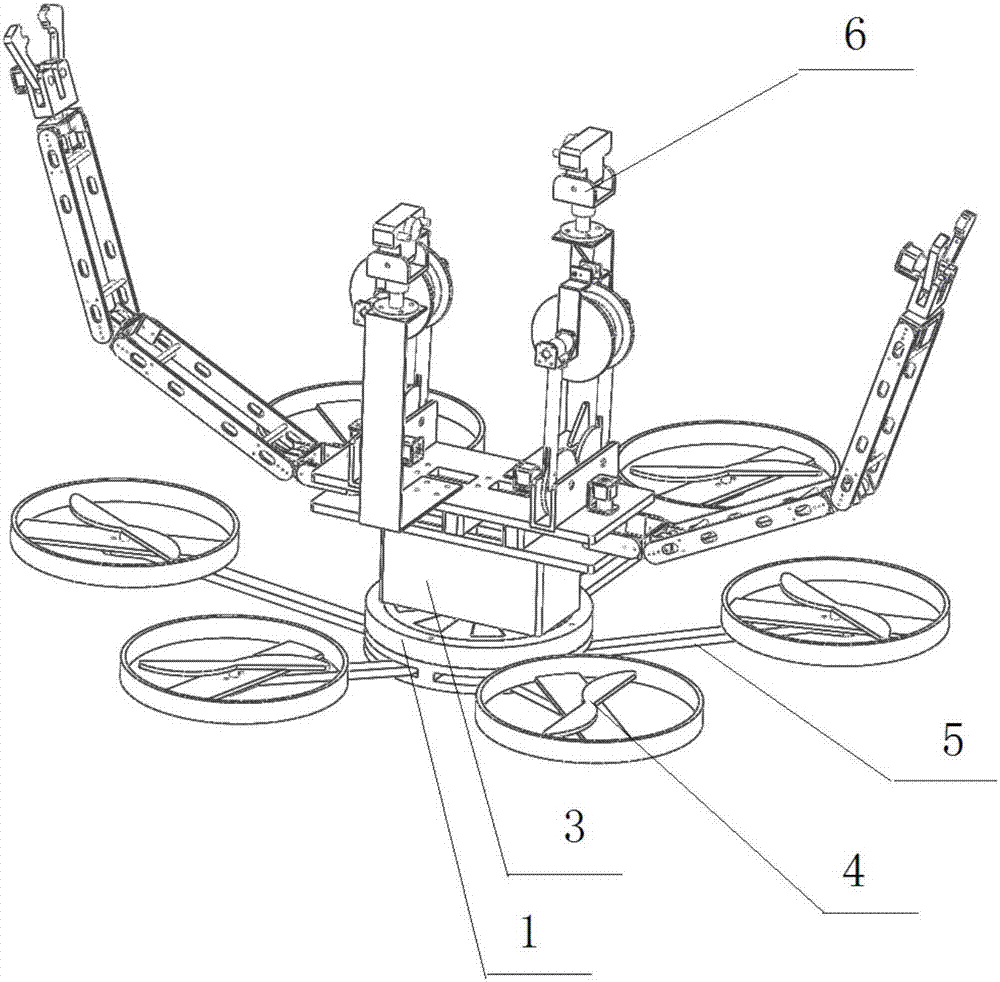

[0057] Such as image 3 As shown, the line inspection robot 6 is adsorbed to the electromagnetic chuck structure 1 on the UAV 5, which facilitates the line inspection robot to go online and offline without being restricted by the geographical environment, and ultimately improves the line inspection efficiency and safety of the line inspection robot.

[0058] Wherein, the line patrol robot 6 is not limited to such as image 3 In the structural form of the line-inspecting robot shown, the line-inspecting robot 6 may also adopt other structural forms of the line-inspecting robot.

[0059] The invention also provides applications such as figure 2 The method for the UAV with electromagnetic sucker to realize the on-line and off-line of the line inspection robot includes:

[0060] When the line patrol robot goes online, place the line patrol robot on the electromagnetic chuck of the drone, and the control circuit controls the electromagnetic chuck to generate a magnetic field, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com