Intelligent water control equipment of intermittent countercurrent rinsing plating piece and automatic water control method thereof

A countercurrent cleaning, intermittent technology, applied in cleaning methods and utensils, cleaning methods using liquids, preparation of detergent mixture compositions, etc., can solve the problems of lack of automatic control means, large water consumption in electroplating cleaning process, etc. Automatically control the effect of saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

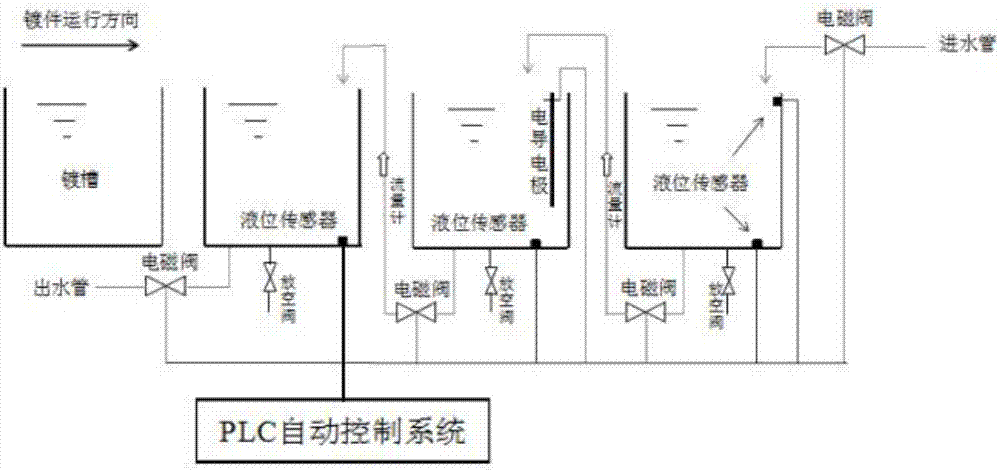

[0024] An intelligent water control device for intermittent countercurrent cleaning of plated parts, comprising a three-stage countercurrent cleaning tank, a PLC automatic control system, a liquid level sensor, a water supply pump, a drainage pump, a water inlet pipe, and a water outlet pipe; the multistage countercurrent cleaning tank is a It consists of three cleaning tanks connected in series to form a first-level cleaning tank, a second-level cleaning tank, and a third-level cleaning tank. The cleaning tanks at all levels are of anti-corrosion steel structure. At the bottom of each cleaning tank, the water inlet pipe of the previous cleaning tank is connected with the water outlet pipe of the latter cleaning tank, and the cleaning water is transported to the final cleaning tank through the water supply pump, and the water flow direction is opposite to the running direction of the plated parts. A flow meter is provided between adjacent two-stage cleaning tanks. The bottom o...

Embodiment 2

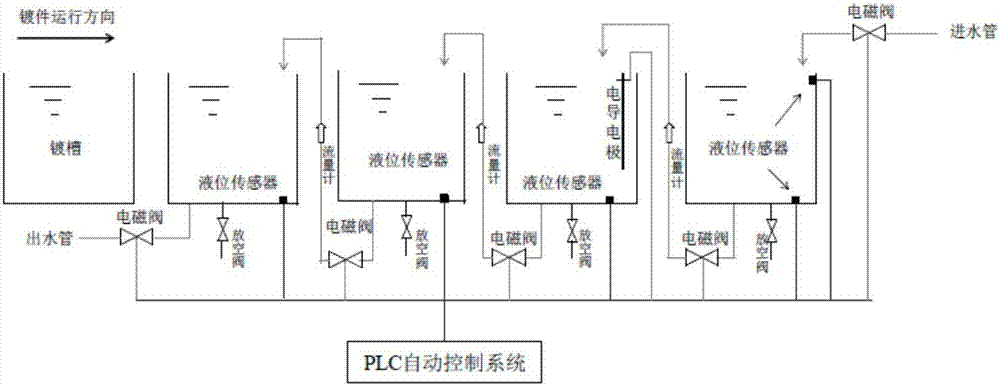

[0031]An intelligent water control device for intermittent countercurrent cleaning of plated parts, including a four-stage countercurrent cleaning tank, a PLC automatic control system, a liquid level sensor, a water supply pump, a drainage pump, a water inlet pipe, and a water outlet pipe; the multistage countercurrent cleaning tank is It is composed of 4 cleaning tanks connected in series, which are the first-level cleaning tank, the second-level cleaning tank, the third-level cleaning tank, and the fourth-level cleaning tank. , the outlet pipe is set at the bottom of the cleaning tank at each level, the water inlet pipe of the previous cleaning tank is connected to the outlet pipe of the subsequent cleaning tank, and the cleaning water is transported to the final cleaning tank through the water supply pump, and the direction of water flow is consistent with the operation of the plated parts in the opposite direction. A flow meter is provided between adjacent two-stage cleani...

Embodiment 3

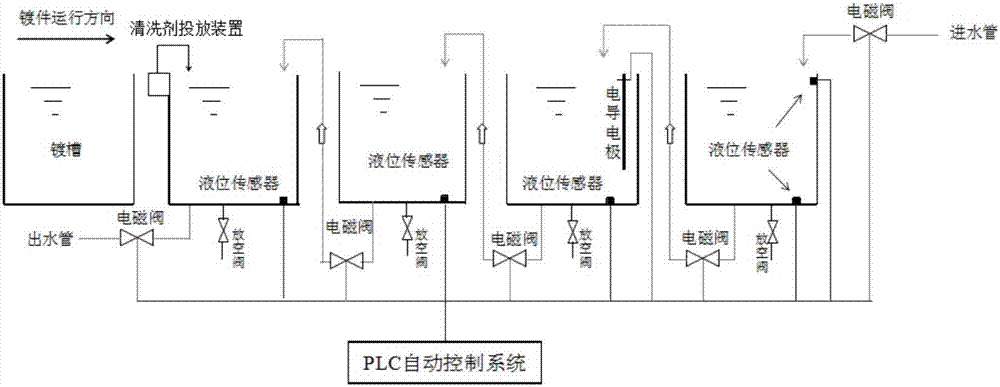

[0038] An intelligent water control device for intermittent countercurrent cleaning of plated parts, including a four-stage countercurrent cleaning tank, a PLC automatic control system, a liquid level sensor, a water supply pump, a drainage pump, a water inlet pipe, and a water outlet pipe; the multistage countercurrent cleaning tank is It is composed of 4 cleaning tanks connected in series, which are the first-level cleaning tank, the second-level cleaning tank, the third-level cleaning tank, and the fourth-level cleaning tank. , the outlet pipe is set at the bottom of the cleaning tank at each level, the water inlet pipe of the previous cleaning tank is connected to the outlet pipe of the subsequent cleaning tank, and the cleaning water is transported to the final cleaning tank through the water supply pump, and the direction of water flow is consistent with the operation of the plated parts in the opposite direction. The delivery pump is a flow pump. The bottoms of the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com