Heating furnace load detecting method by photosensitive device

A technology of a photosensitive device and a detection method, which is applied in the field of heating furnace heating, can solve problems such as hidden safety hazards, affecting the life and performance of electrical appliances, and achieve the effects of preventing excessive local heating, optimizing heating effect, and preventing heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

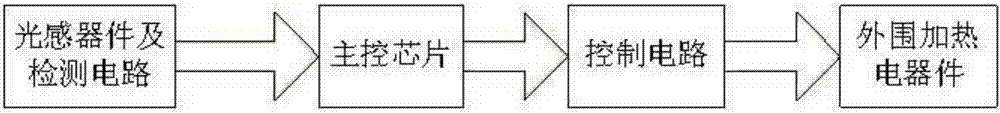

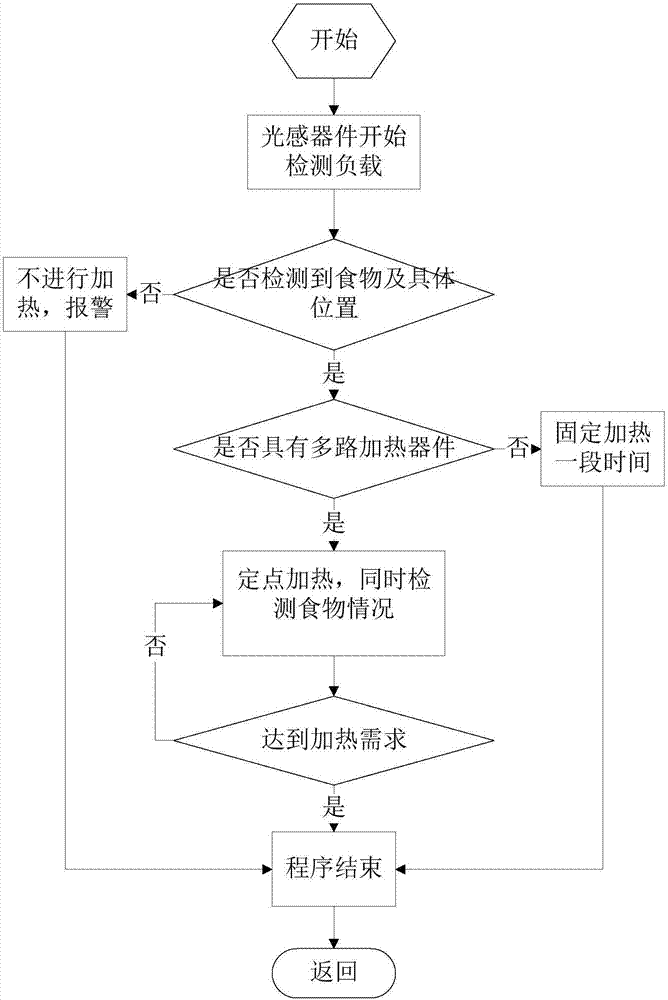

[0014] Such as figure 1 , 2 As shown, the detection method of the photosensitive device of the present embodiment on the load of the heating furnace, the detection system adopted in the method includes a photosensitive device and a detection circuit, a main control chip, a control circuit and a peripheral heating electrical device, and the photosensitive device And the output terminal of the detection circuit is connected with the control circuit through the main control chip, and the output terminal of the control circuit is connected with the peripheral heating electric device. Install multi-channel photosensitive devices (front, back, left and right, and up) in the cavity of heating furnaces such as microwave ovens and ovens. Through a reasonable layout, the shape and size of the load in the cavity can be detected, as well as the shape change during the heating process....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com