Thick steel plate for tank giving weld heat affected zone with excellent toughness

A technology of welding heat-affected and thick steel plates, which is applied in the field of welding heat-affected parts, can solve problems such as non-formation, and achieve the effects of good efficiency, excellent HAZ toughness, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

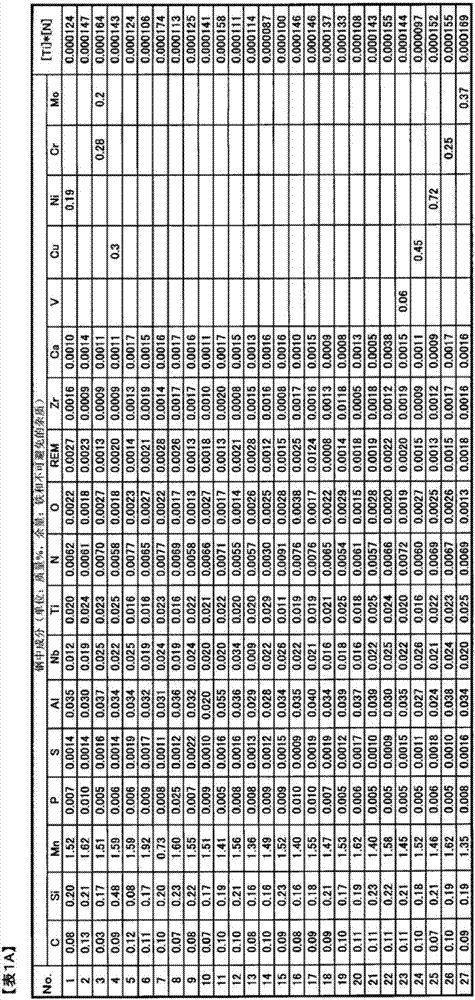

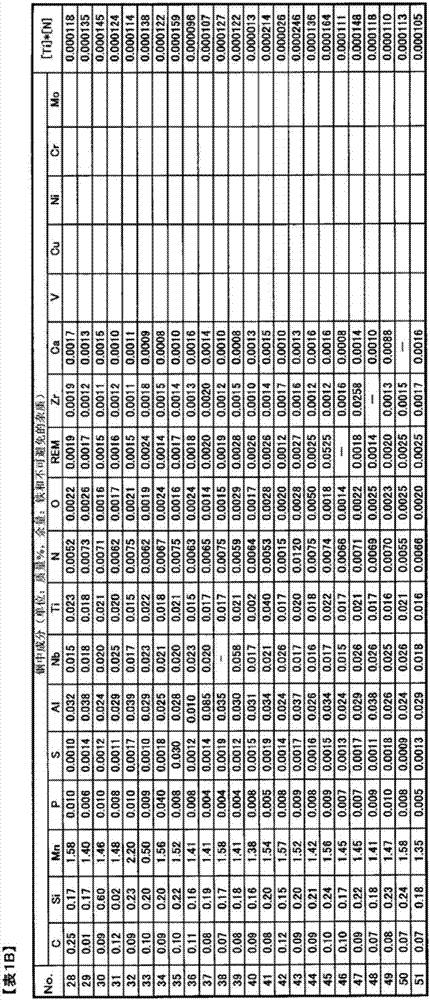

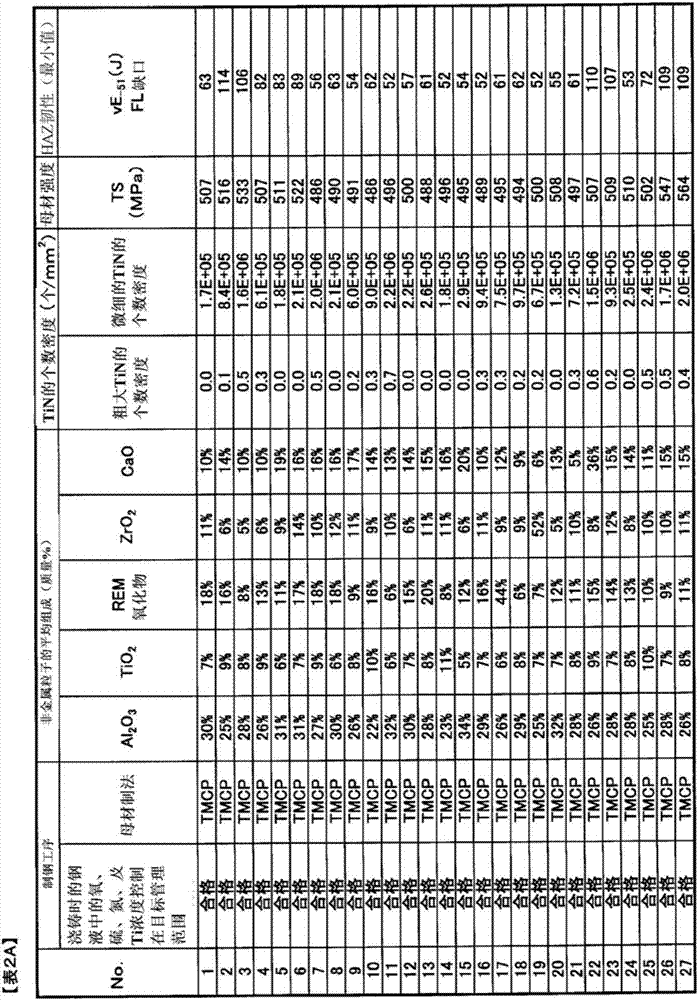

[0112] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited by the following examples, and can also be modified and implemented within the scope of meeting the aforementioned and hereinafter-described gist, and these are all included in the technical scope of the present invention .

[0113] First, steel having the composition shown in Table 1 was melted in a vacuum melting furnace, and a 240-ton billet was obtained using the obtained molten steel. Specifically, during smelting, after controlling the amount of dissolved oxygen in molten steel to 0.002 to 0.01% by mass % by using deoxidation of Mn, Si, and Al, the order of Ti→(REM, Zr)→Ca Each element was added while controlling the time from Ti addition to Ca addition to 3 to 20 minutes, and the cooling time in the temperature range of 1500 to 1450° C. during casting was made within 300 seconds.

[0114] In this example, REM was added in the form of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com