Flexible pcm fabric

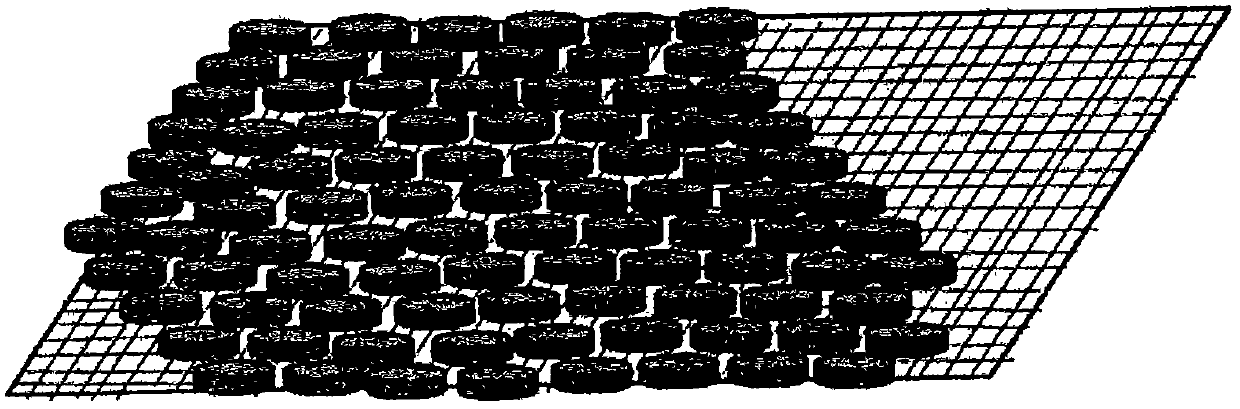

一种面料、柔性的技术,应用在柔性PCM面料领域,能够解决PCM微粒流入的能力限制等问题,达到低加工温度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A ZSE 40 type twin-screw extruder (Leistritz company) with an aspect ratio of 52:1 was first used to prepare PCM polymer particles from the following raw materials:

[0029] -80wt% PCM material (Sasol GmbH's ether 12, long chain dialkyl ether, melting point is 32°C)

[0030] -10 wt% styrene block copolymer SEEPS (polystyrene-b-poly(ethylene-ethylene / propylene)-b-polystyrene; Kuraray Co.Ltd.'s 4055)

[0031] -5wt% hydroxy-terminated styrene block copolymer (Kuraray Co.Ltd.'s HG 252) - 5 wt% crystalline ethylene-butene copolymer (Typ 6201B from JSR Dynaron).

[0032] The extrusion die was connected to the cutting head of an underwater pelletizer (Gala underwater pelletizer, Gala Inc.) through an adapter plate. Particles with a diameter of 4-5 mm are obtained.

[0033] The obtained particles had a heat storage capacity of 215 J / g at the PCM phase transition temperature with a switching temperature of 32°C.

[0034] The PCM polymer particles were dried in a circula...

Embodiment 2

[0041] Similar to that described in Example 1, PCM polymer particles of the following composition were prepared in a ZSE 40 Leistritz twin-screw extruder with downstream underwater pelletizer:

[0042] -80wt% PCM material (Sasol GmbH's ether 12, long chain dialkyl ether)

[0043] - 10 wt% styrene block copolymer SEBS (polystyrene-b-poly(ethylene / butylene)-b-polystyrene; Septon 8004 by Kuraray Co. Ltd.)

[0044] -5wt% hydroxy-terminated styrene block copolymer (Septon HG 252 from Kuraray Co. Ltd.)

[0045] - 5 wt% crystalline ethylene-butene copolymer (Typ 6201B of JSR Dynaron),

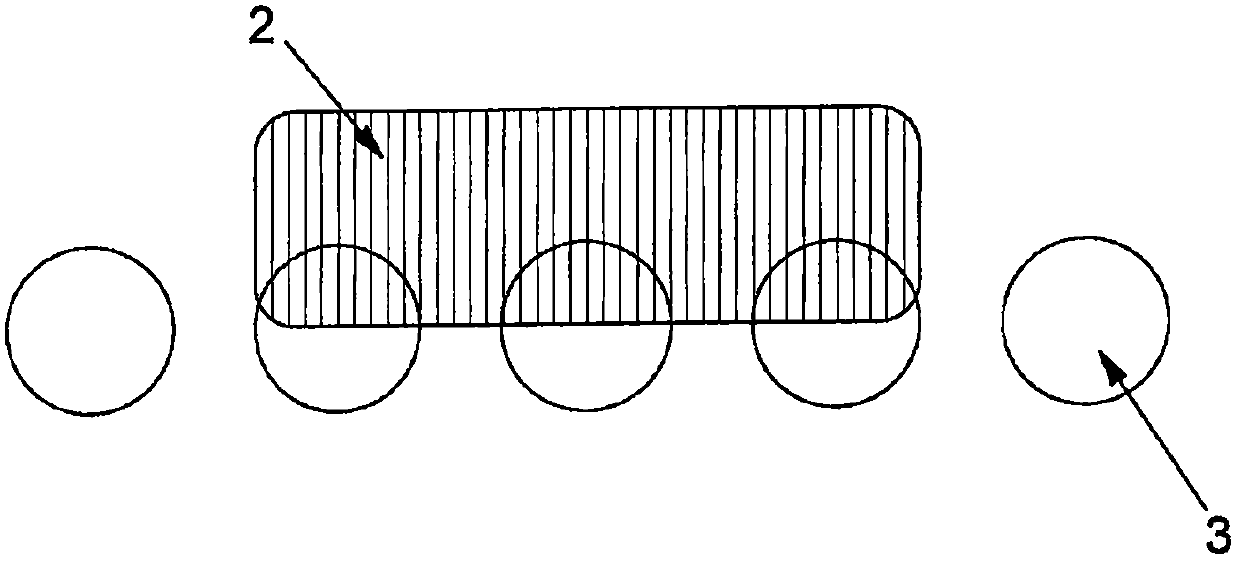

[0046] After drying it is applied to a coarse mesh polyamide fabric in a single-screw extruder using a special casting tool.

[0047]The polymer fabrics with PCM polymer castings (rectangular or cylindrical) were then sprayed on both sides with a 5% by mass polyamide solution (composed of Ultramid 1C) and the excess solvent was evaporated at room temperature.

[0048] The polyamide coating has a ...

Embodiment 3

[0050] PCM polymer granules were also prepared in a ZSE 40 Leistritz twin-screw extruder and downstream underwater pelletizer similarly to that described in Example 1, which were dried in a single-screw extruder using a special casting tool Apply to coarse mesh polyamide fabric.

[0051] But here the composition of matter of the PCM polymer is changed:

[0052] -70wt% PCM material (Sasol GmbH's ether 16, long chain dialkyl ether)

[0053] -8wt% styrene block copolymer SEEPS (Septon4055 of Kuraray Co.Ltd)

[0054] -4wt% hydroxy-terminated styrene block copolymer (SeptonHG 252 from Kuraray Co.Ltd.)

[0055] -3wt% crystalline ethylene-butene copolymer (JSR Dynaron's Typ 6201B)

[0056] -15wt% zinc oxide powder

[0057] Prepared in a ZSE 40 Leistritz twin-screw extruder with a downstream underwater pelletizer, it is dried and coated onto a coarse mesh polyamide fabric in a single-screw extruder using a specific casting tool.

[0058] Zinc oxide not only increases thermal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com