Deep processing method of kiwi fruits and prepared kiwi fruit wine

A technology of kiwi fruit and dosage, applied in the preparation of alcoholic beverages, food science and other directions, can solve the problems of low juice yield, no good solution, fruit residue, difficult separation of wine liquid, etc., to achieve higher alcohol content and superior quality. , the effect of mellow substances increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

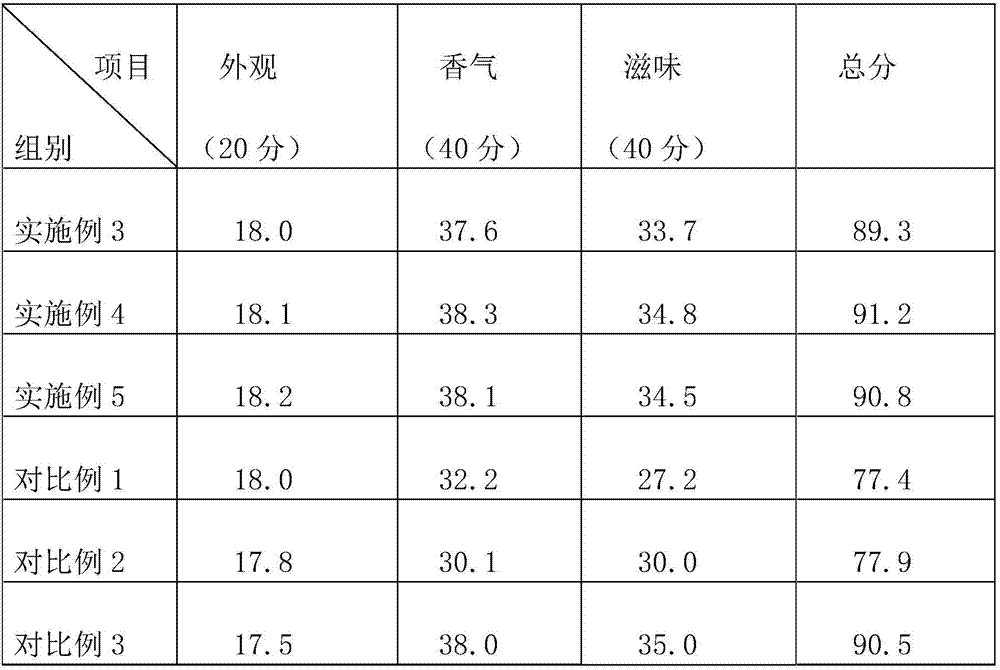

Examples

Embodiment 1

[0036] A kind of kiwifruit deep processing method, the steps are as follows:

[0037] Collect the picked kiwi fruit, the maturity distribution of kiwi fruit is 50-80%;

[0038] These kiwifruits are made into pulp, and potassium metabisulfite and pectinase are added in the pulp of kiwifruit, the addition of potassium metabisulfite is 0.03‰ of the pulp weight, and the addition of pectinase is 0.01% of the pulp weight. ‰, mix well, and place at room temperature for 5h;

[0039] Then add compound glucoamylase, the unit of compound glucoamylase is 1 million U, the added amount of compound glucoamylase is 0.1% of the weight of pulp, and enzymatically hydrolyze to obtain pulp of kiwi fruit tissue with uniform maturity.

Embodiment 2

[0041] A kind of kiwifruit deep processing method, the steps are as follows:

[0042] Collect the picked kiwi fruit, the maturity distribution of kiwi fruit is 50-80%;

[0043] These kiwifruits are made into pulp, and potassium metabisulfite and pectinase are added in the pulp of kiwifruit, the addition of potassium metabisulfite is 0.05‰ of the pulp weight, and the addition of pectinase is 0.03‰ of the pulp weight. ‰, mix well, and place at room temperature for 5h;

[0044] Then add compound glucoamylase, the unit of compound glucoamylase is 1 million U, the added amount of compound glucoamylase is 0.3% of the weight of pulp, and enzymatically hydrolyze to obtain pulp of kiwi fruit tissue with uniform maturity.

Embodiment 3

[0046] A kind of kiwifruit deep processing method, the steps are as follows:

[0047] Collect the picked kiwi fruit, the maturity distribution of kiwi fruit is 50-80%;

[0048]These kiwifruits are made into pulp, and potassium metabisulfite and pectinase are added in the pulp of kiwifruit, the addition of potassium metabisulfite is 0.08‰ of the pulp weight, and the addition of pectinase is 0.05‰ of the pulp weight. ‰, mix well, and place at room temperature for 4 hours;

[0049] Then add compound glucoamylase, the unit of compound glucoamylase is 1 million U, the added amount of compound glucoamylase is 0.5% of the weight of pulp, and enzymatically hydrolyze to obtain pulp of kiwi fruit tissue with uniform maturity.

[0050] The enzymolysis temperature in Example 1-3 can be 50-65°C, 15-30°C, or 30-40°C. The higher the temperature, the faster the enzymolysis speed. The enzymolysis temperature depends on the subsequent processing. Just ask for a selection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com