Short gear shaft efficient machining method

A processing method and wheel shaft technology, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve the problems of wasting materials, failing to meet high efficiency, low cost requirements, increasing costs, etc., and achieve cost reduction , Save material costs, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

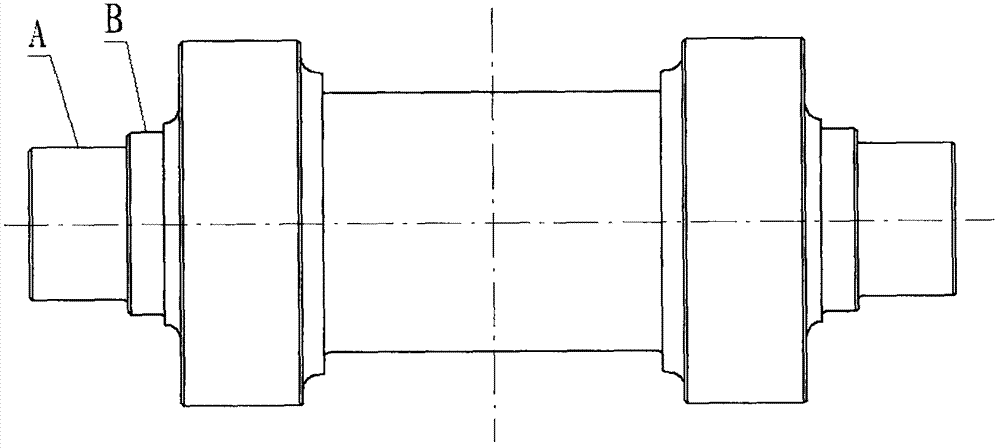

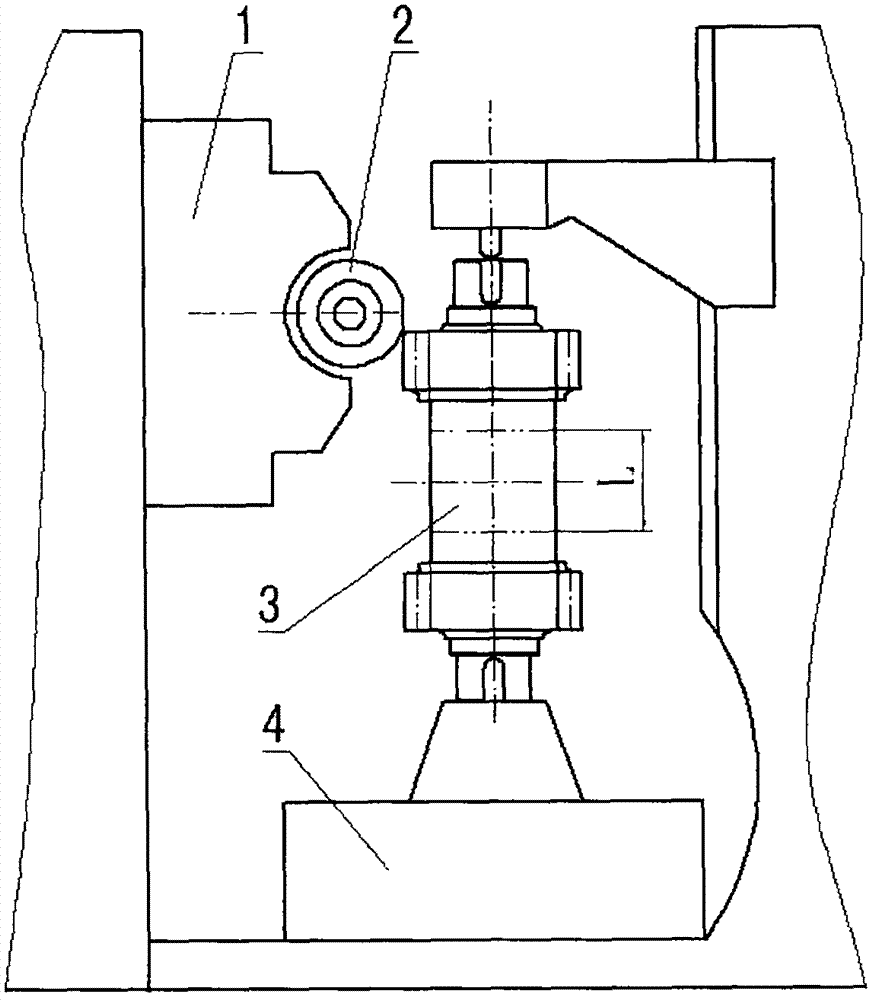

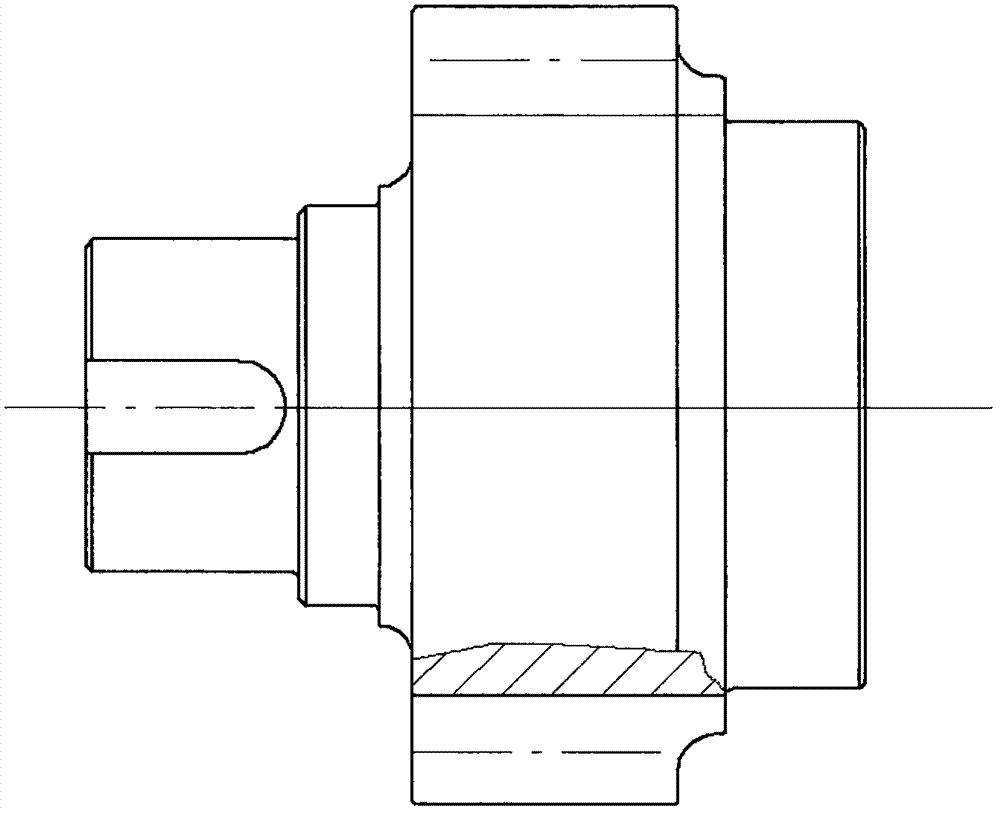

[0011] Depend on Figure 1~3 It can be seen that the processing of the short gear shaft is completed according to the following steps:

[0012] Step 1, calculate blanking size, and carry out blank blanking and heat treatment;

[0013] Step 2, rough and finish turning the workpiece;

[0014] Step 3, initial grinding of outer circles A and B;

[0015] Step 4, milling the key grooves at both ends of the workpiece;

[0016] Step 5. Align two points on the outer circle of A and B, and the runout is within 0.05mm. Roughly and finely mill the teeth to ensure the common normal line size required by the process;

[0017] Step 6, the middle outer circle is protected against seepage, and the gear is carburized and quenched;

[0018] Step 7, the outer circle and rounded corners in the middle of the second finishing car;

[0019] Step 8, finely grind the outer circles of A and B at both ends, the middle outer circle and the addendum circle, and grind the end faces;

[0020] Step 9: A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com