Shield tunnel initial sealing device and use method thereof

A technology for sealing devices and shield tunnels, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as high costs, achieve the effects of reducing construction costs, avoiding sand gushing, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

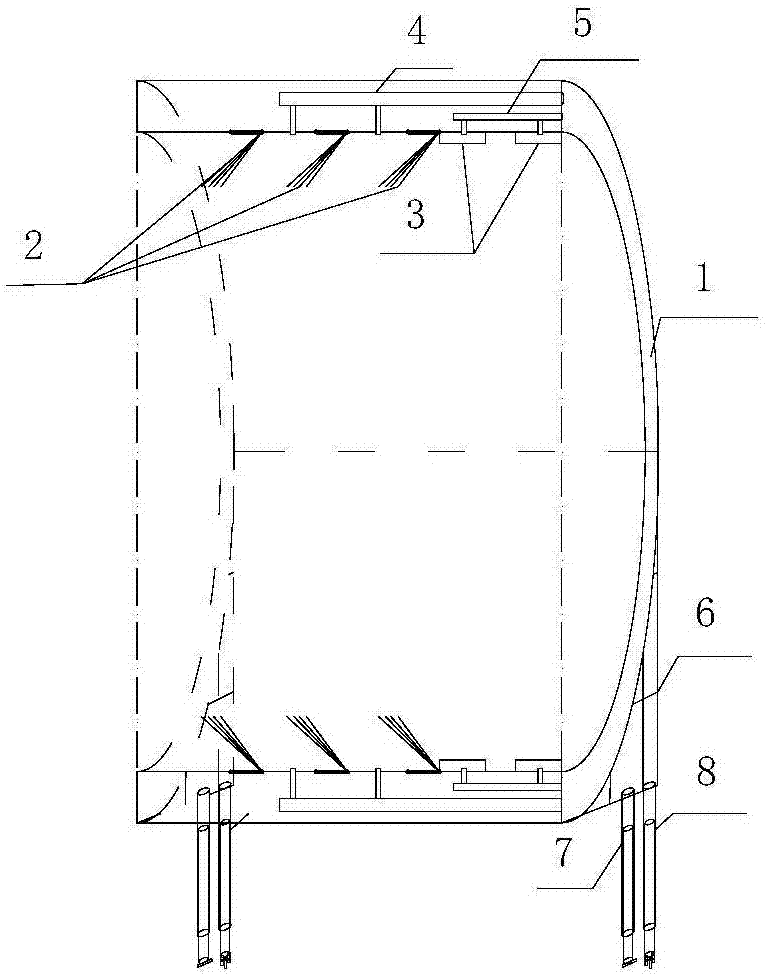

[0026] A shield tunnel starting sealing device includes the following components: starting sealing barrel 1, highly elastic tail brush 2, air bag 3, grease pipeline 4, inflation pipeline 5, support frame 6, retractable support system 7 and retractable wheels to 8.

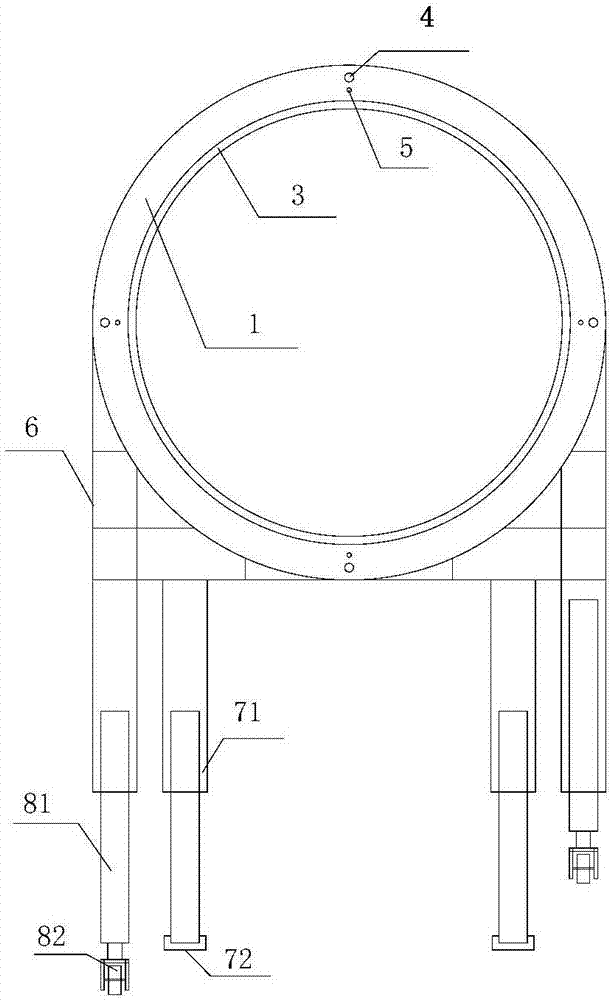

[0027] Such as figure 1 , figure 2 As shown, the inner wall of the originating sealed barrel 1 is respectively provided with at least 2 annular high-elastic tail brushes 2 and at least 1 annular air bag 3, and the wall of the originating sealed barrel 1 is respectively provided with a grease pipeline 4 and Inflatable pipeline 5, the gap formed between two adjacent highly elastic tail brushes 2 communicates with grease pipeline 4, air bag 3 communicates with inflatable pipeline 5, and the lower part of the outer wall of the originating sealed bucket 1 is provided with a support frame 6, and the support frame 6 The bottom is provided with a telescopic support system 7 and a telescopic wheel set 8.

[0028] Such a...

specific Embodiment 2

[0032] The method for using the shield tunnel originating sealing device shown in the above specific embodiment 1 comprises the following steps:

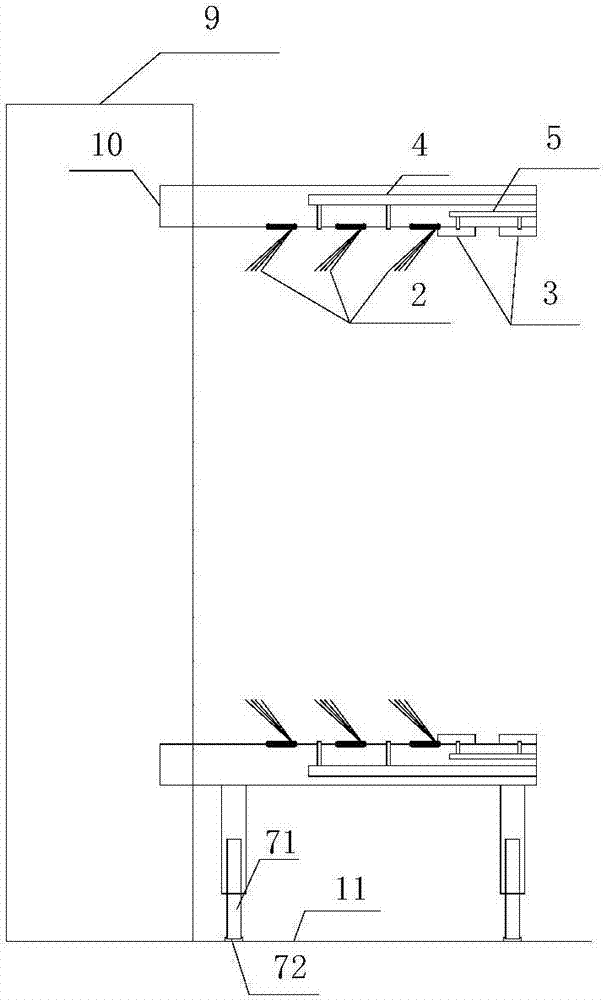

[0033] Step 1: Positioning and installation of the shield starting sealing device. Such as figure 2 and image 3 As shown in Fig. 1, move the initial sealing device of the shield tunnel to the designated position through the telescopic wheel set 8, extend the telescopic support system 7, retract the telescopic wheel set 8, and fix the initial sealing device of the shield tunnel on the bottom support 11, further fix the originating sealed barrel 1 on the embedded part 10 of the originating end structure 9 by welding.

[0034] Step 2: Seal the gap between the shield machine 12 and the originating sealing device. Such as Figure 4 As shown, the shield machine 12 is placed in the starting sealing barrel 1, and the shield tail grease 15 is injected between the high elastic tail brush 2 through the grease pipe 4 to ensure that the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com