Scramjet engine based on detonation combustion

A technology of scramjet and detonation combustion, which is applied in ramjet engines, mechanical equipment, etc., can solve the problems of not considering the application of engines, and the conceptual design of new scramjet engines has not been reported, so as to ensure detonation Detonation and control function, improving fuel premixing efficiency, increasing the effect of fuel premixing distance and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

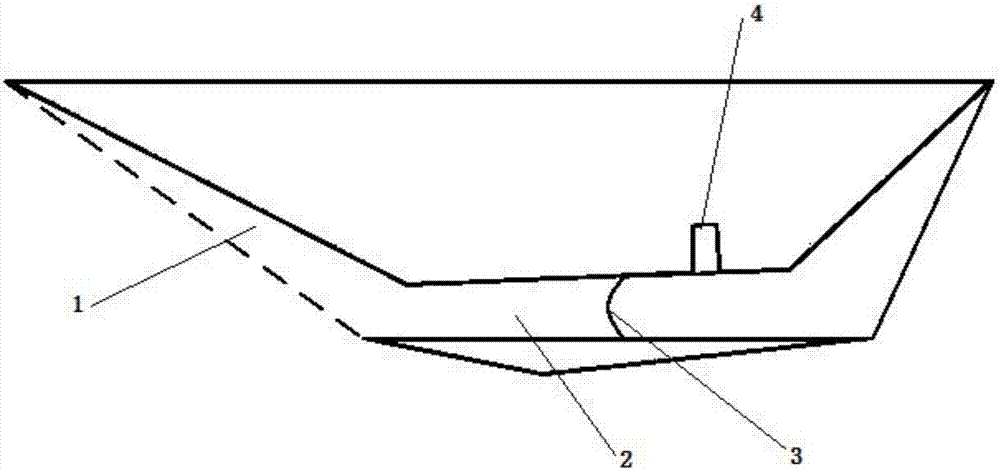

[0025] The invention provides a scramjet based on knocking combustion. In a new scramjet based on knocking combustion, the compression of supersonic air flow, fuel injection, and mixing with compressed air can be realized in the combustion chamber. The thermal jet's detonation initiation and the dynamic and stable control of detonation combustion, so as to finally achieve stable thrust performance. The invention is mainly designed from the engine's intake port structure, fuel injection structure, detonation structure and combustion chamber dynamic control structure.

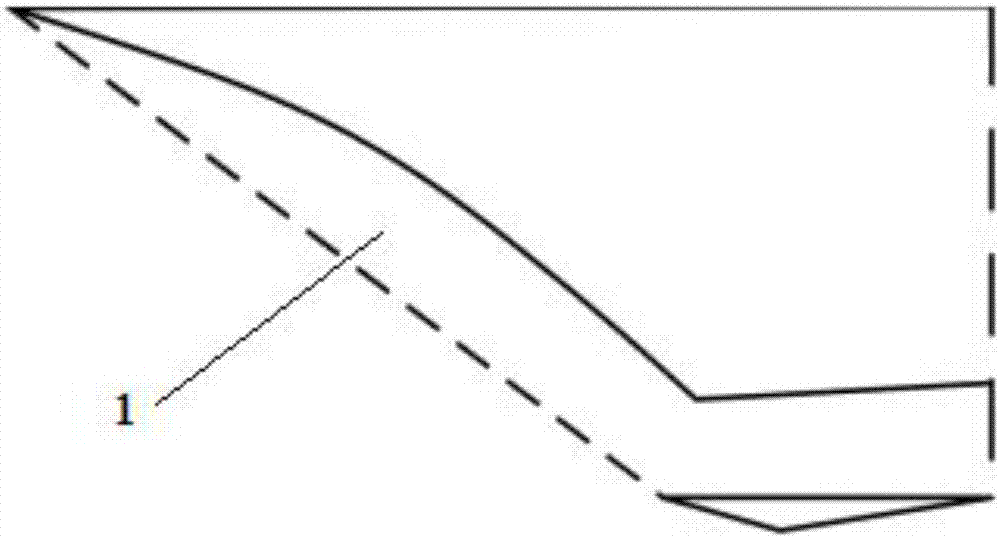

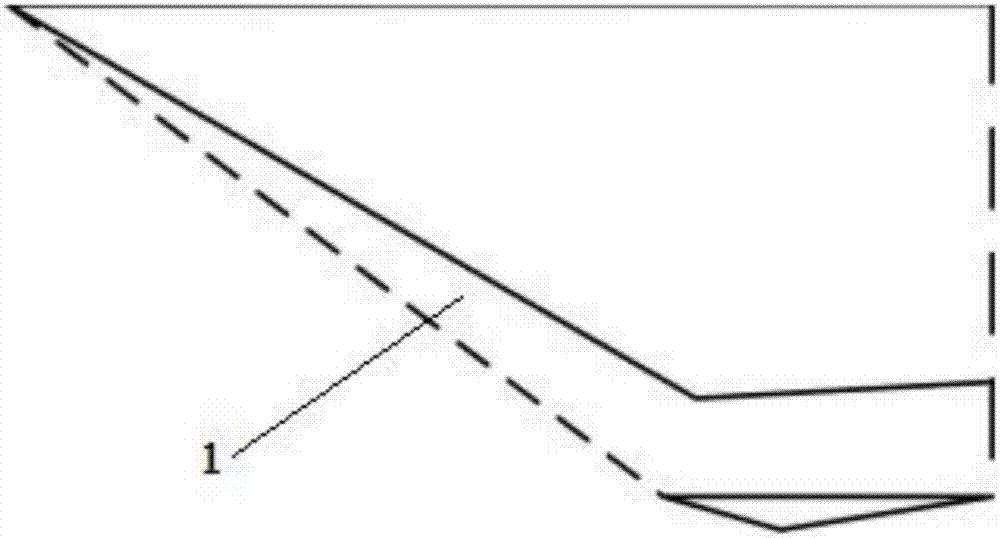

[0026] Reference figure 1 , This embodiment includes an intake port 1 and a combustion chamber 2. For the intake port, the isobaric combustion in the combustion chamber of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com