360-degree full field-of-view angle diffractive optical element and method for designing same

A technology of diffractive optical elements and design methods, applied in the field of micro-optics, can solve the problems of limited and limited diffracted light range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

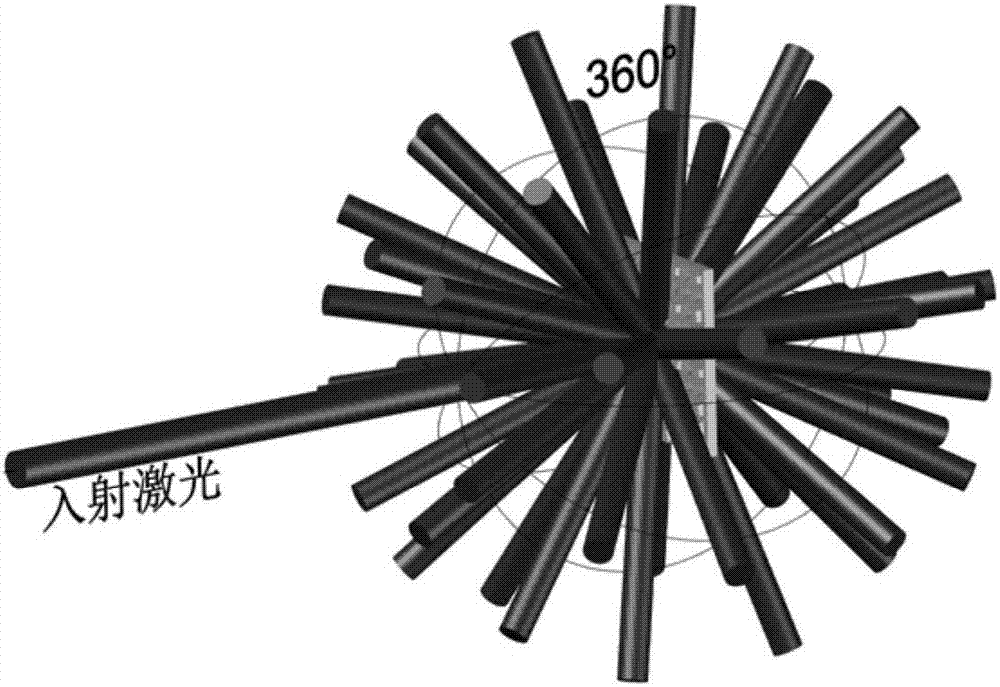

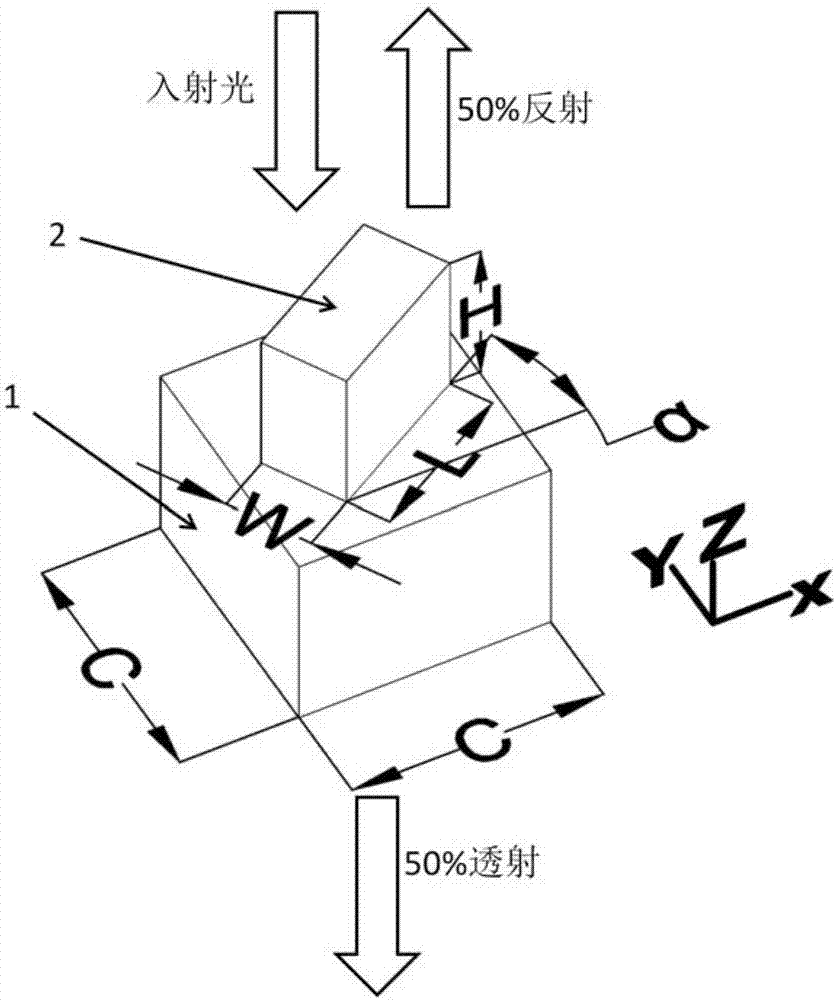

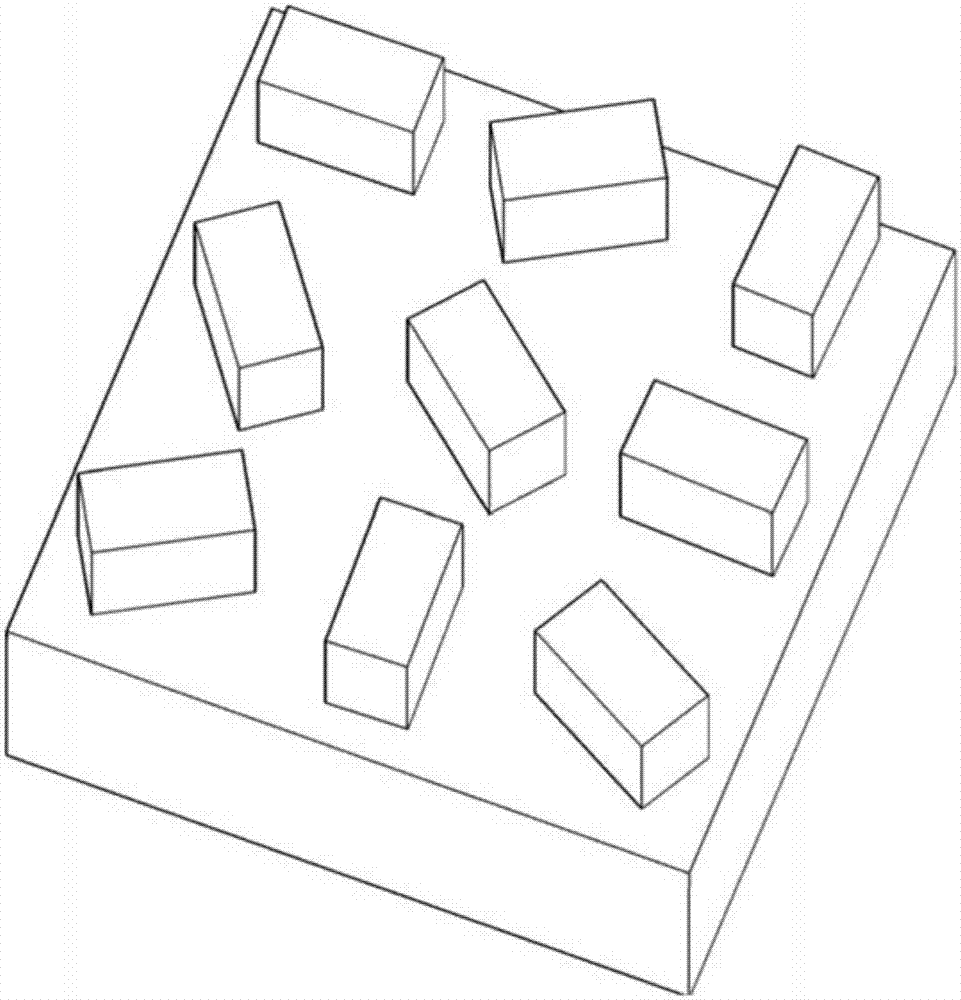

[0027] Such as Figure 1 to Figure 3 As shown, the present invention provides a diffractive optical element with a full field of view of 360°, including a base layer 1 made of a dielectric material and several nano-bricks 2, the base layer and the nano-bricks are transparent to the response wavelength, and the materials of the two are different; Among them, each nano-brick is a cuboid with the same size, and the length, width, and height of each nano-brick are all sub-wavelength scales; the nano-bricks are arranged on the base layer at different orientation angles to form a unit structure. To carry out arbitrary continuous modulation on the phase of the incident light, and make the modulated light field transmit forward and backward synchronously.

[0028] A 360° full field angle diffractive optical element of the present invention utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com