Multifunctional cascaded tail-end power output device

A power output, multi-functional technology, applied in the direction of coupling device, two-part connecting device, connecting device components, etc., can solve the problems of plugs that are difficult to meet different specifications, troublesome, and bulky sockets, and achieve simple structure and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] There are three implementation modes for the socket part of this embodiment, as follows:

Embodiment approach 1

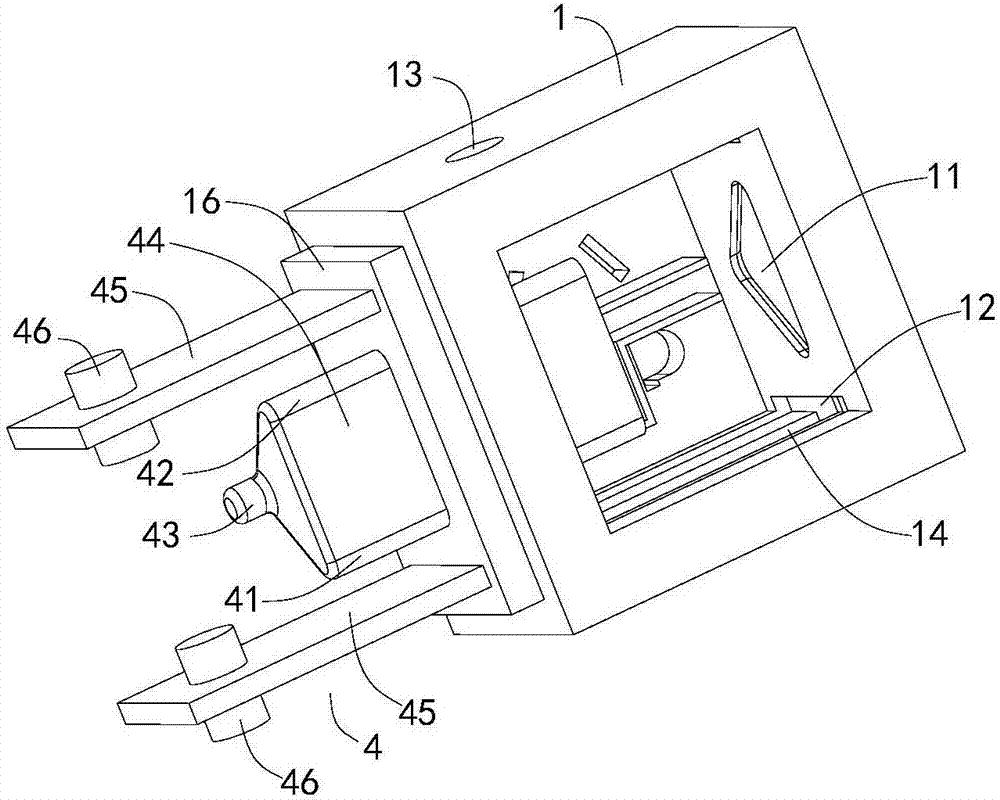

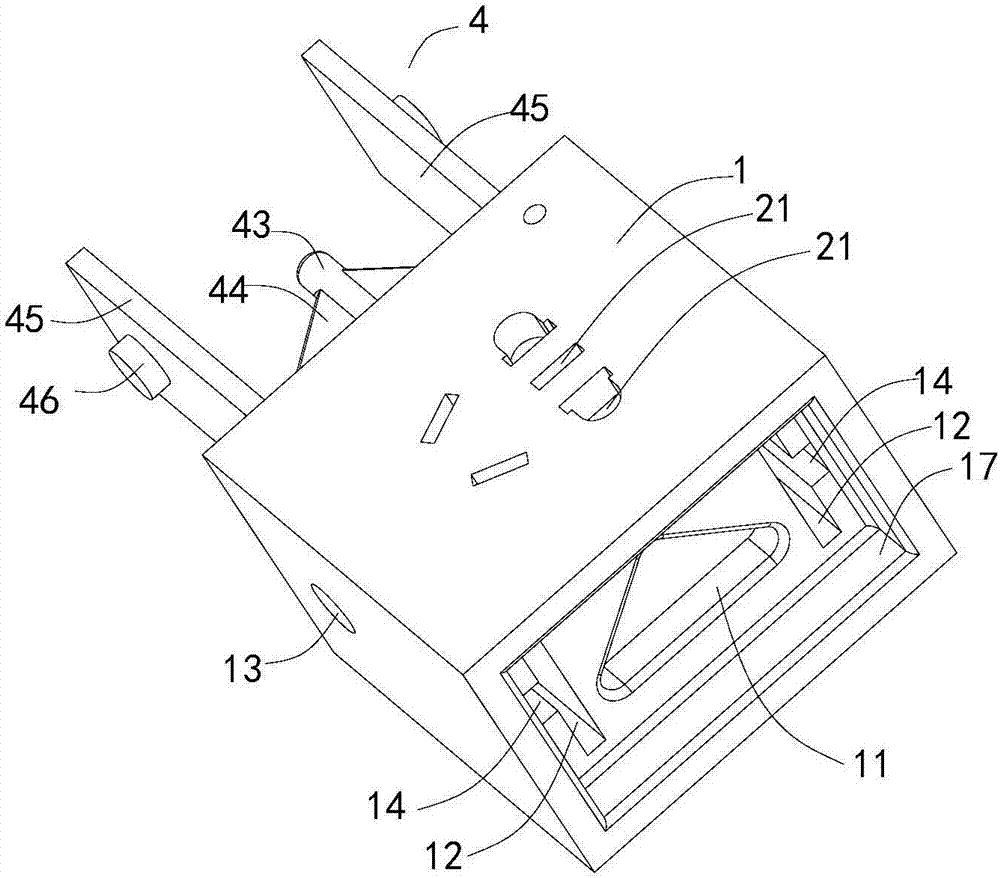

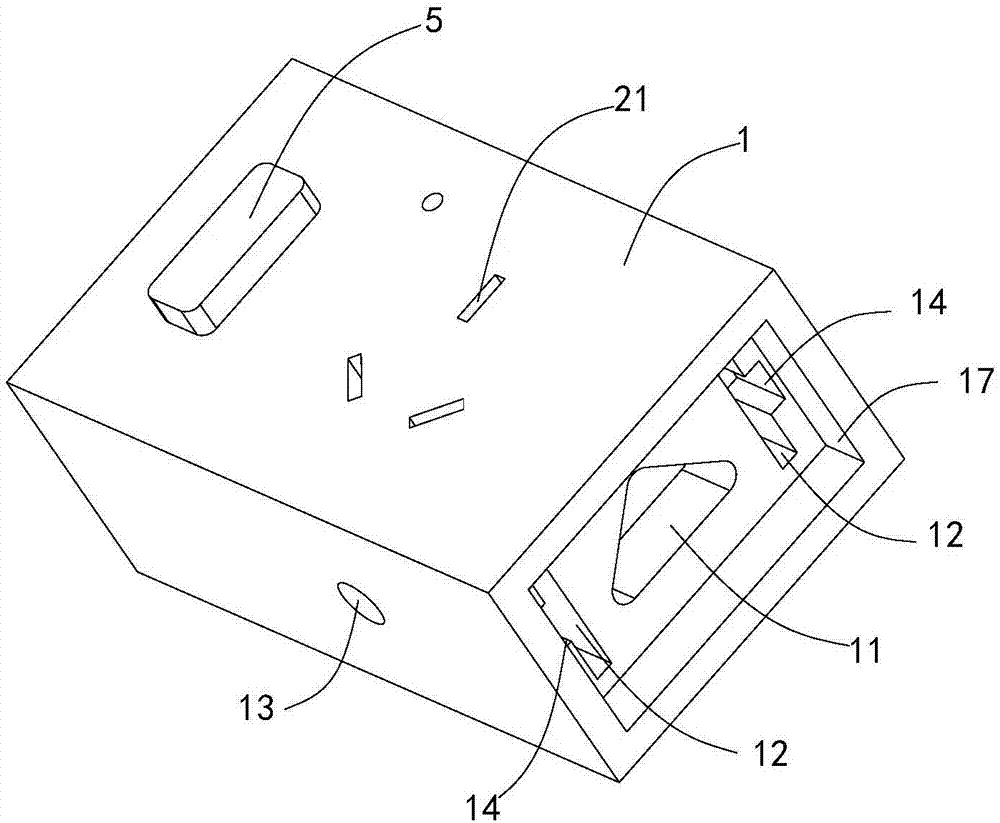

[0051] Embodiment 1, such as figure 1 and figure 2 As shown, the insertion part 4 of this embodiment may be a square columnar structure, a circular columnar structure or a polygonal columnar structure. The lengths of the zero wire connection post 41 , the live wire connection post 42 and the ground wire connection post 43 in this embodiment can be equal and fixed on the outer wall of the insertion post 44 , when the insertion post 44 is inserted into the first socket 11 , the neutral line connection post 41 , the live line connection post 42 and the ground line connection post 43 of the two connected cascaded socket units 1 are all connected to each other. The lengths of the zero wire connecting post, the live wire connecting post and the ground wire connecting post are all longer than the length of the plugging post.

[0052] Such as figure 1 As shown, in a preferred solution of this embodiment, the insertion post 44 is in the shape of a triangular prism, and the neutral ...

Embodiment approach 2

[0053] Embodiment 2, such as figure 1 and figure 2 As shown, the socket part 4 of this embodiment also includes a socket plate 45, one end of which is fixed to the head end or tail end of the cascaded socket unit 1 and is located at the socket One side of the column 44, the other end of which extends away from the cascaded socket unit 1; the socket includes a second socket 12, and the socket board 45 is adapted to be inserted into the second socket 12 Inside; the plug-in board 45 is arranged parallel to the side wall of the cascaded socket unit 1, and the side wall is provided with a slide groove 14 and a snap-in hole 13 or a snap-in groove. The plug-in board 45 A locking protrusion 46 is provided at a position close to the locking hole 13 or the locking groove, and the locking protrusion 46 is adapted to be locked in the locking hole 13 or the locking groove. The chute 14 is arranged along the axial direction of the insertion column 44, and the chute 14 communicates the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com