Device integrating centrifugal pre-dedusting and uniform distribution of air flow

A technology of uniform airflow distribution and pre-dust removal, which is applied in combination devices, separation methods, auxiliary pretreatment, etc., can solve the problems of uneven flow distribution coefficient of filter bags, easy blockage of air intake pipes, and uneven distribution of internal airflow. Extend the service life and operating effect, increase the operating effect, the effect of uniform flow distribution coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the specific structure and working process of the present invention, the preferred implementation modes of the present invention are described in detail below.

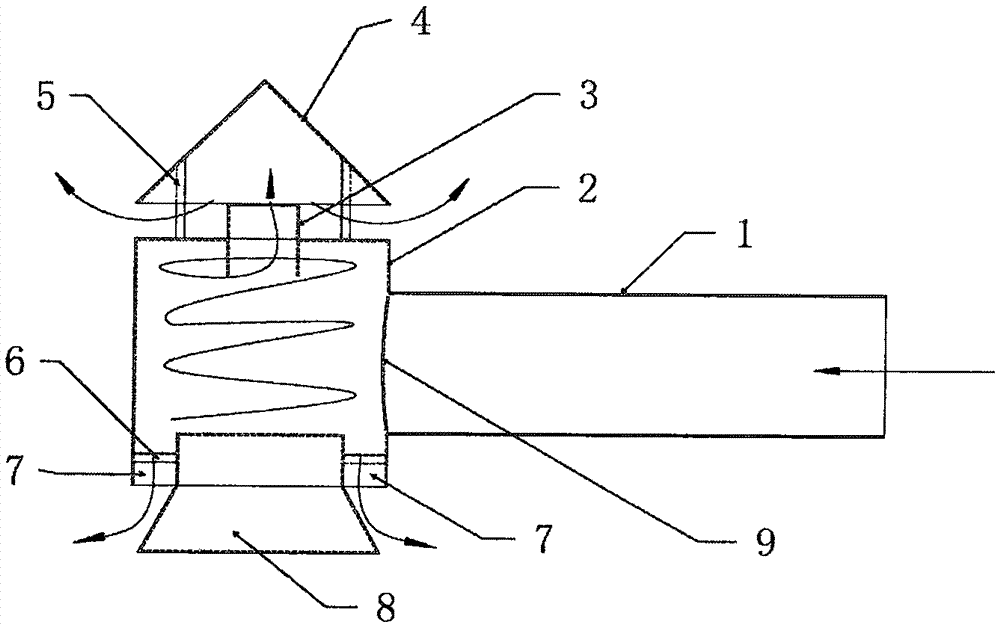

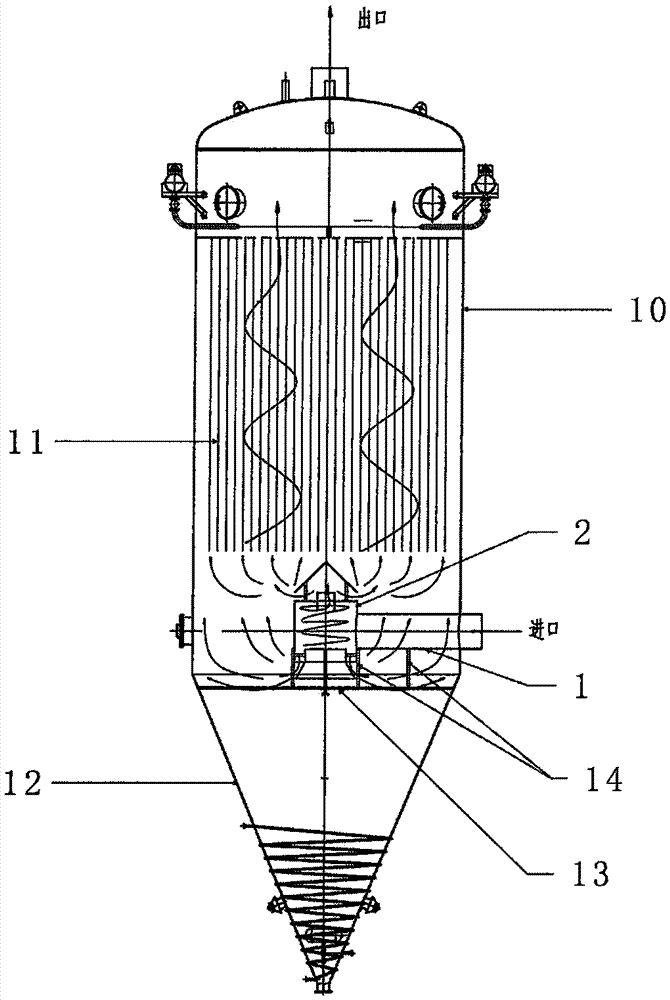

[0016] First refer to figure 1 , the present invention includes a cylinder 2, which is a cylindrical shape rolled from a steel plate. The top of the cylinder is non-opening and the bottom is open.

[0017] An exhaust pipe 3 that coincides with the longitudinal axis of the cylinder protrudes from the top of the cylinder 2, and at the same time, a longitudinal support 5 is welded on the four sides of the top of the cylinder, and the longitudinal support adopts a 50mm *50mm equilateral angle steel. A top conical deflector 4 is arranged directly above the exhaust pipe 3, and the four sides of the conical deflector are welded on four longitudinal angle steels at the top of the cylinder body, and are supported and fixed by the four longitudinal angle steels. The conical deflector here...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com