Automatic connection machine for straight thread sleeve of reinforcing bar

A straight thread sleeve and automatic connection technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven quality of manual connection, unguaranteed pass rate, and low work efficiency, so as to improve work efficiency and work quality, avoiding accidental injuries, and strong work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below through specific examples.

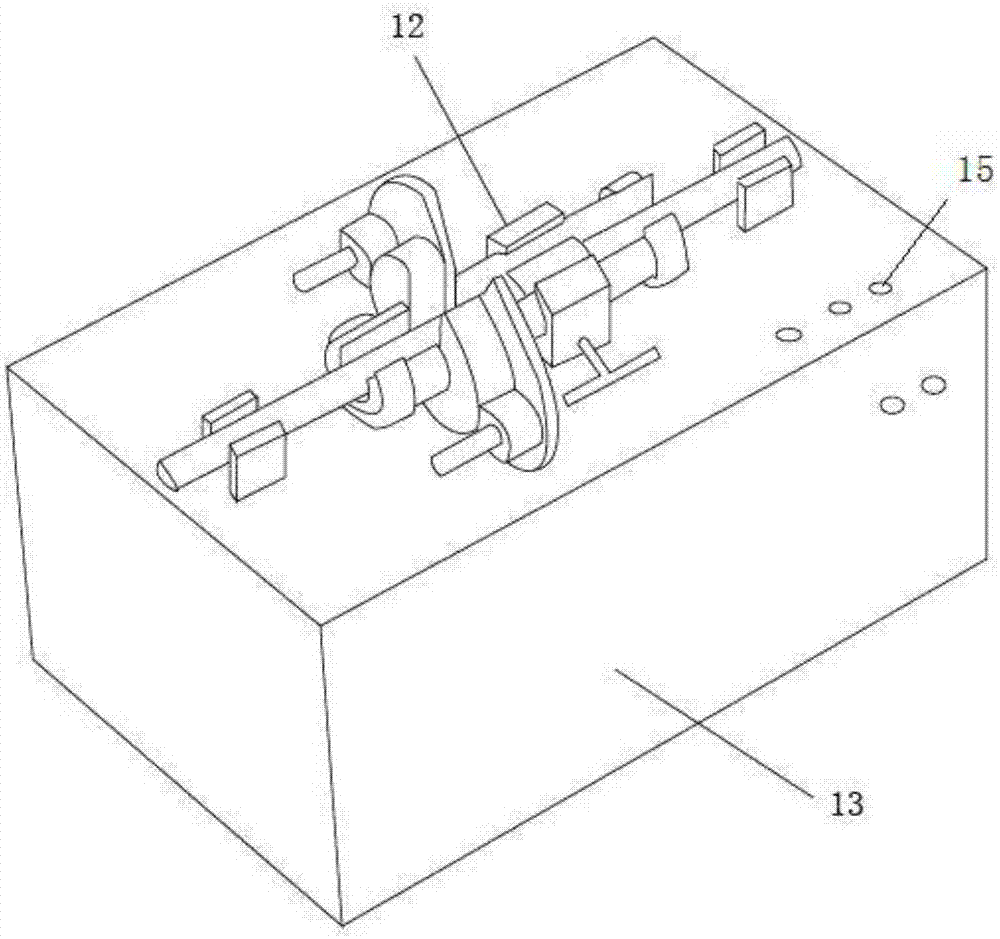

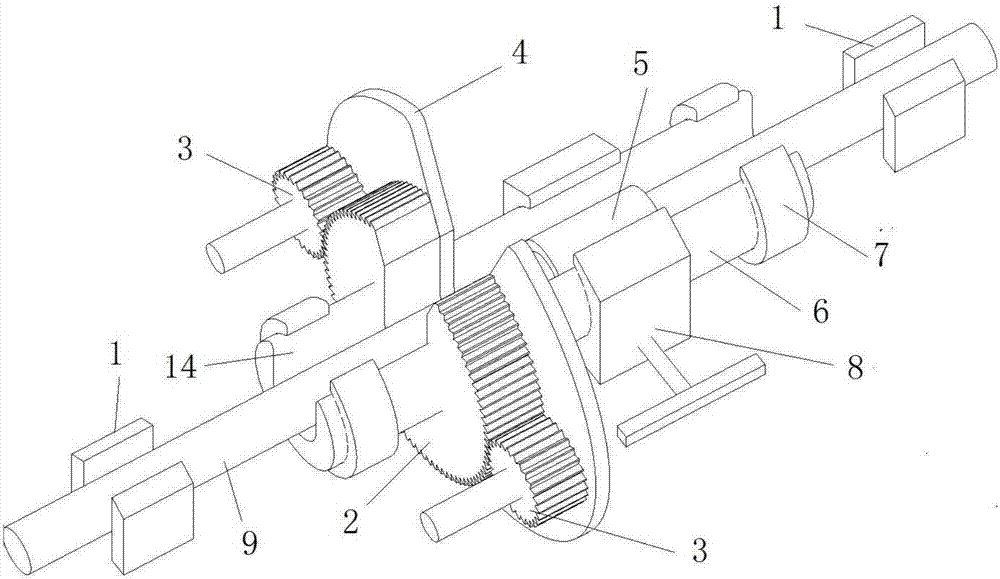

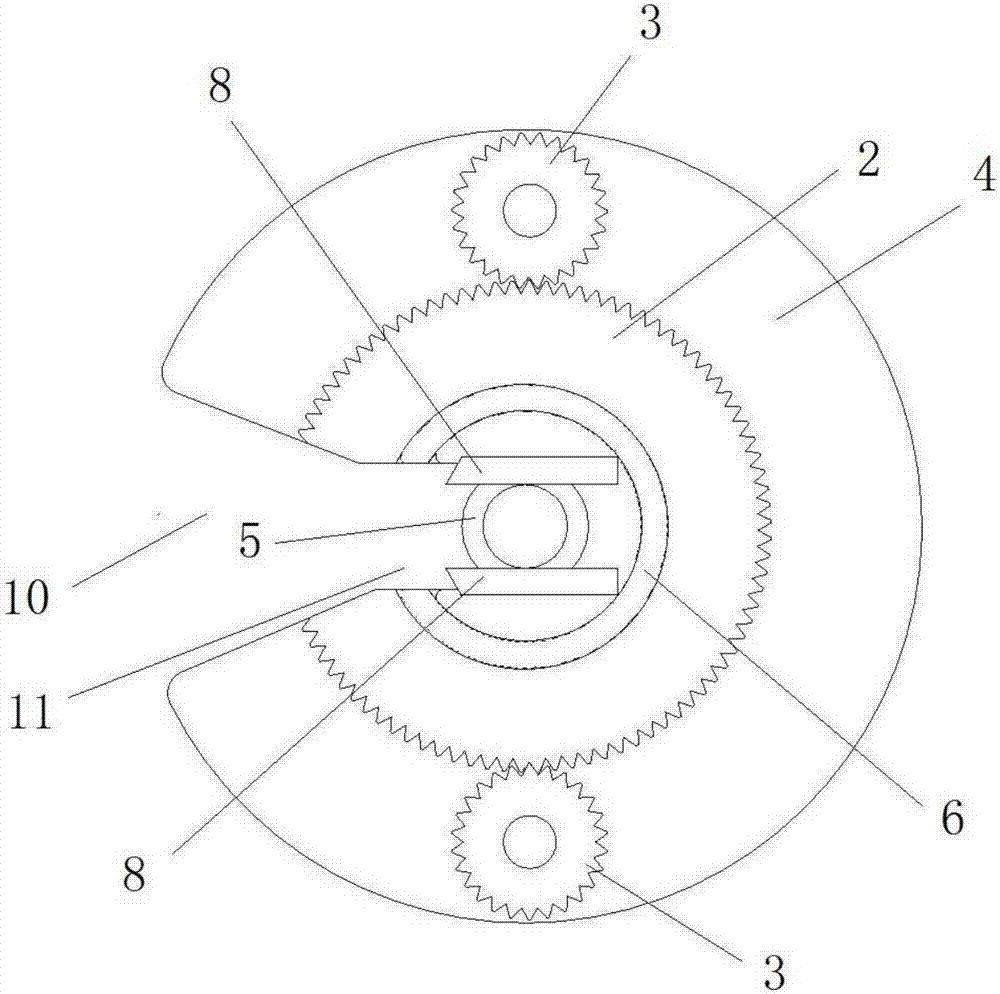

[0031] An automatic connecting machine for steel bar straight thread sleeves, comprising a casing 13, a head system 12, a hydraulic locking system, a power system, and a control system, the casing 13 is provided with a hydraulic locking system, a power system, and a control system, and the hydraulic locking system The locking system and the power system are respectively connected with the control system. The control system sets the corresponding torque according to the diameter of the sleeve 5. After reaching the set torque value, the power system stops working and the sleeve is loosened. Barrel fastening device 8, press the reset switch, the gear fan-shaped gap 10 automatically returns to the top, then loosen the steel bar clamp 1, take out the connected steel bar member, the power system is a motor, and a protective cover is arranged on the motor;

[0032] A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com