Integrated detection device applied to small aero engine crankshaft

An aero-engine and comprehensive detection technology, applied to measuring devices, instruments, etc., can solve problems such as the inability to obtain absolute values and the inability to group parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is a comprehensive detection system for the crankshaft of a small aero-engine.

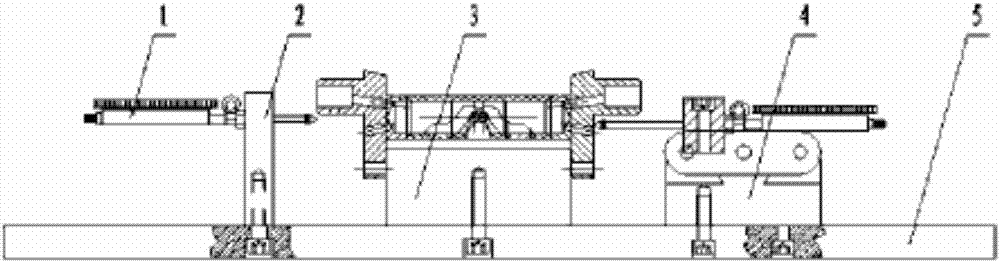

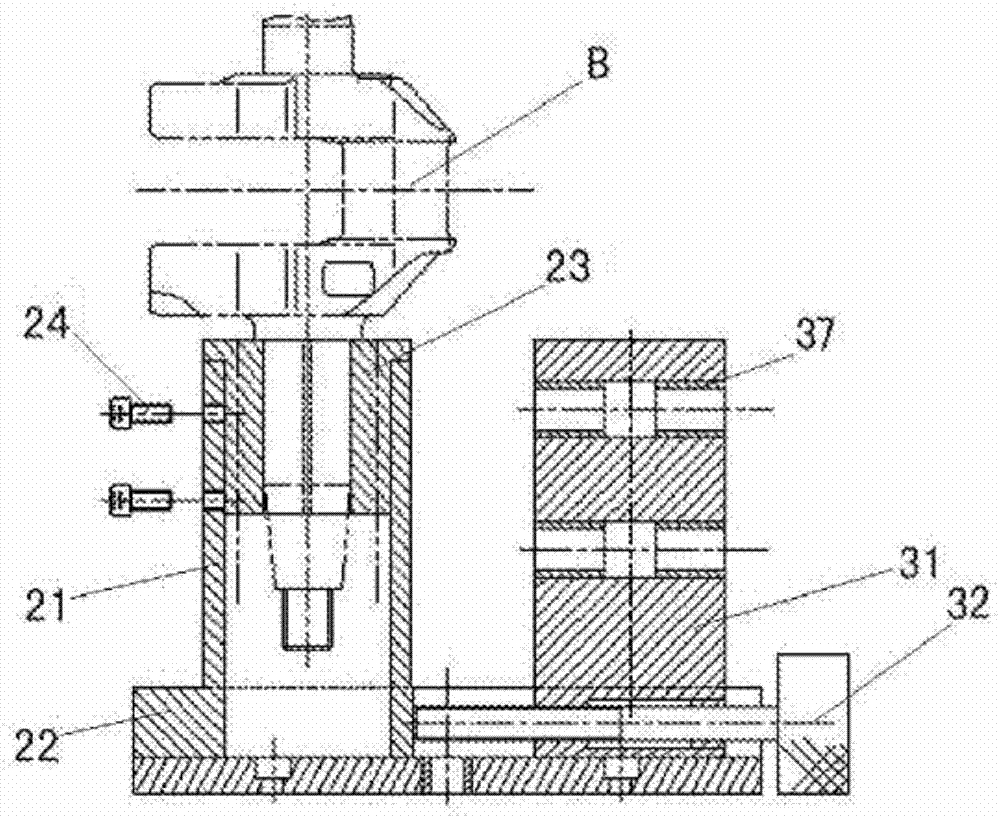

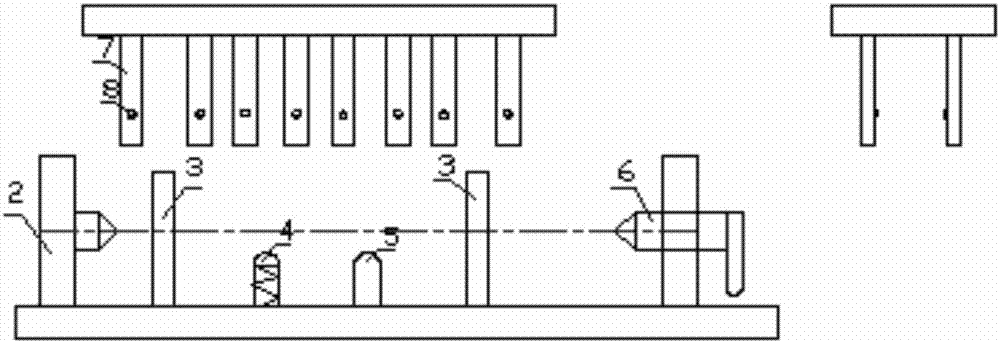

[0026] refer to image 3 , Figure 4 , Figure 5 , the present embodiment is used for the comprehensive detection device of the crankshaft of small aero-engine, which consists of a base 1, a fixed top 2, a movable top 6, a V-shaped block 3, a fixed fulcrum 5, an elastic fulcrum 4, a detection bracket 7, a detection head 8, a fixed bracket, Composed of guide rail and motor; among them, the fixed top 2 and the movable top 6 are respectively fixed on the two ends of the base 1, and the fixed top 2, the movable top 6 and the central blind holes at both ends of the crankshaft are positioned to clamp the crankshaft to facilitate measurement. Two V-shaped blocks 3 are respectively installed on the upper part of the base 1 between the fixed top 2 and the movable top 6, symmetrically installed, and the positions supported by the two V-shaped blocks 3 are respectively at the two mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com