Tunnel initial stage support waterproof board weld air tightness detection method

A technology for air tightness detection and initial support. It is used in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, and measuring devices. It can solve problems affecting judgment, gas leakage, and air tightness detection. The problem of large error in the result can prevent the distortion of the result and improve the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Test design: Testing the airtightness of the lap weld of the tunnel waterproofing plate. Two welds of the waterproofing plate K0+098 and K0+102 in a certain tunnel section are selected for testing. The measuring point 1 and measuring point 2 of each weld are tested respectively. It is arranged on the left and right walls of the tunnel. The height of measuring point 1 is 1.3m, and the height of measuring point 2 is 1.4m.

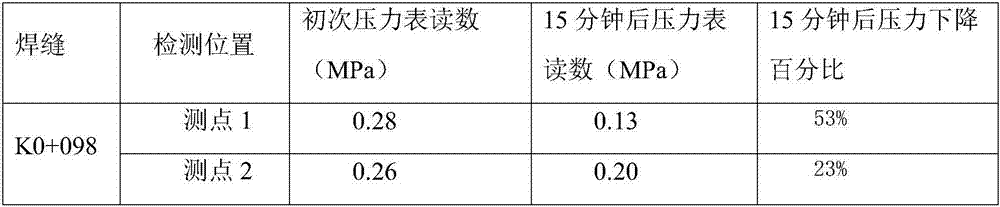

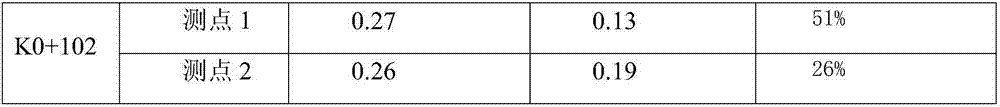

[0016] Method 1: The traditional detection method (the method disclosed in the background art) is used to detect the measuring points 1 and 2 of the two welds. The results are shown in Table 1.

[0017] Table 1 Method 1 Inspection data table of lap weld inflatable method for waterproof board

[0018]

[0019]

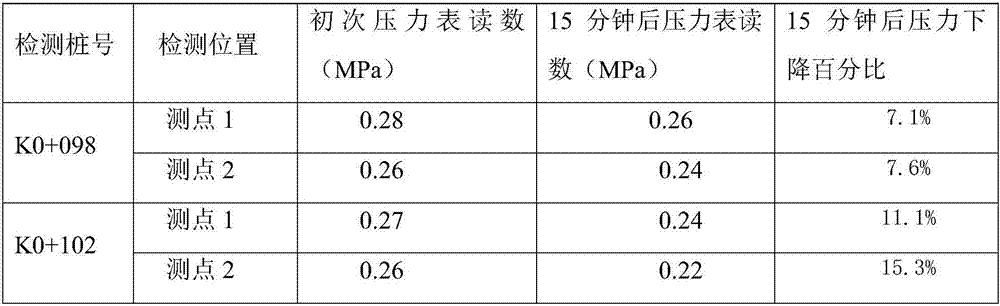

[0020] Method 2: The detection method of the present invention is used for detection. The specific detection steps are as follows: 1. After double welding seam welding on both sides of the joint of the waterproof board with an electric climbing welder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com