Novel exhaust system

An exhaust system, a new type of technology, applied in aerodynamic tests, measuring devices, instruments, etc., to achieve the effects of long continuous operation, stable airflow pressure in the flow field, and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

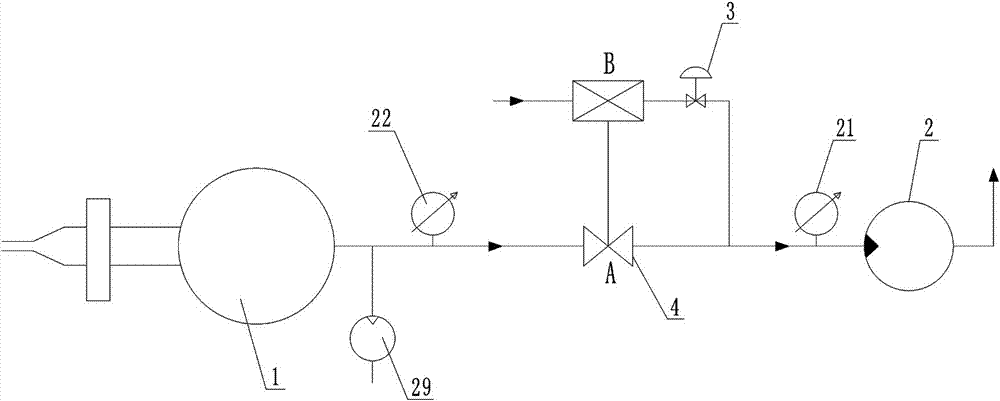

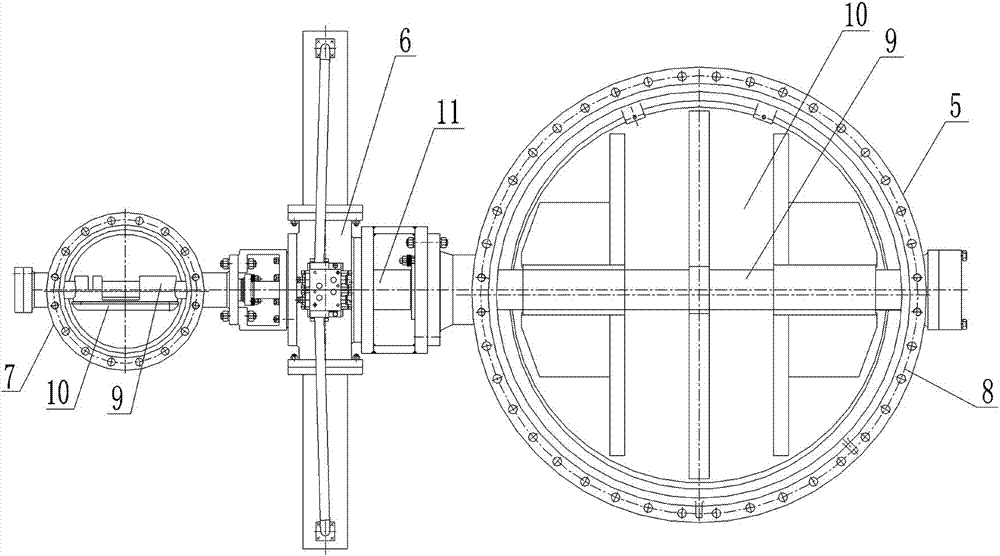

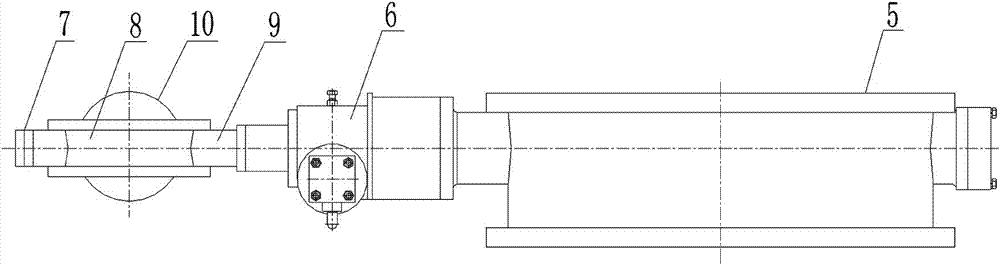

[0023] Such as Figure 1~3 As shown, a novel exhaust system includes a vacuum spherical tank 1, a centrifugal vacuum pump 2, a regulating valve 3 and a vacuum switching valve 4, and the vacuum switching valve 4 is located between the vacuum spherical tank 1 and the centrifugal vacuum pump 2; The vacuum switching valve 4 described above is composed of a valve A5, a motor 6 and a valve B7. The motor 6 is located between the valve A5 and the valve B7. Both the valve A5 and the valve B7 are composed of a valve body 8, a valve shaft 9 and a valve plate 10. The valve shaft 9 is installed vertically through the valve body 8 and the two ends of the valve shaft 9 rotate on both sides of the valve body 8, the valve plate 10 located in the valve body 8 is installed on the valve shaft 9, the valve body 8 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com