A chemical complexation cleaning method for polysilicon equipment

A polysilicon and equipment technology, applied in the field of chemical complex cleaning of polysilicon equipment, can solve problems such as inability to produce products, achieve the effects of long running time, avoid corrosion damage, and facilitate fine adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

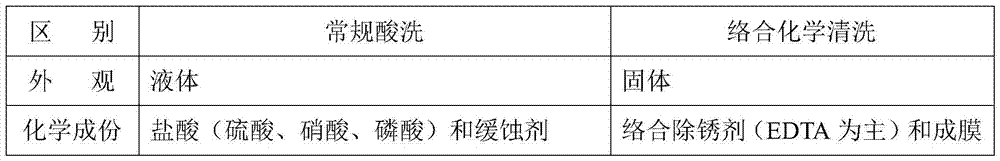

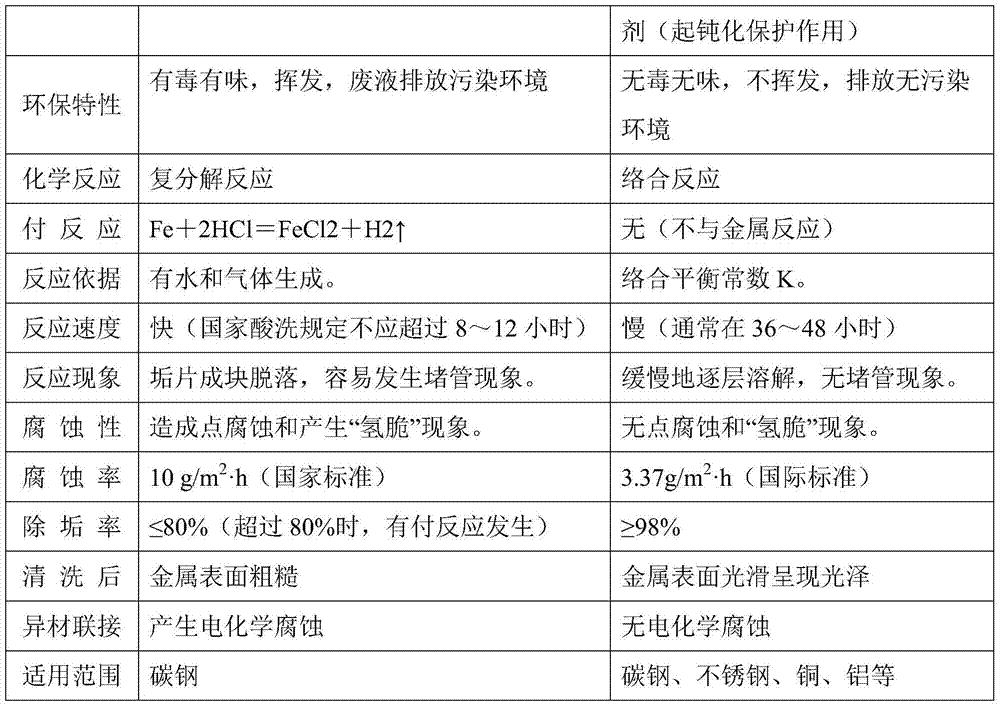

Image

Examples

Embodiment 1

[0052] Embodiment 1 is to the cleaning of pipeline, tubing class

[0053] 1) Pretreatment of carbon steel pipes before cleaning:

[0054] Severely corroded carbon steel pipes, welding slag, spatter, and paint must first be manually treated to achieve the degree of fine degreasing, and then visually inspected. Slightly corroded carbon steel pipes are directly degreased.

[0055] 2) Degreasing process:

[0056] 1. Crude degreasing process: the pipeline with serious oil pollution is firstly degreased, and the organic solvent trichlorethylene is used as the crude degreasing agent.

[0057] 2. Fine degreasing process: Clean with non-ionic surfactant, and dry with oil-free hot air after degreasing.

[0058] Rinse with water: Rinse with water immediately after degreasing, at room temperature for 30 minutes.

[0059] The nonionic surfactant is a solution of a mixture of fatty alcohol polyoxyethylene ether, chelating agent and dispersant, wherein the mass fraction of fatty alcohol ...

Embodiment 2

[0074] The cleaning of embodiment 2 tower class, tank class

[0075] 1. Formulation of process:

[0076] According to the equipment type, material, technical requirements, cleaning quality requirements, and the requirements of the construction party, the equipment cleaning plan is formulated. Equipment cleaning can be divided into two parts: spray cleaning and circulation cleaning. Large-volume equipment such as rectification towers and storage tanks (reaction tanks) are equipped with spray devices according to the degree of corrosion, and spray and circular cleaning are adopted, while other equipment are all circularly cleaned. Circular cleaning implements positive and negative cycle cleaning methods through the cleaning reversing platform to avoid missed cleaning in dead corners. For specific classification equipment connection installation cleaning processes, please refer to the classification cleaning process operating procedures and the attached table.

[0077] 2. Equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com