Close-loop simulation-based distributed load optimization design method for carrier

A technology of distributed load and closed-loop simulation, which is applied in computer-aided design, design optimization/simulation, instrumentation, etc., and can solve the problems of not being able to fully consider the impact, not covering all working conditions, and not being comprehensive enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

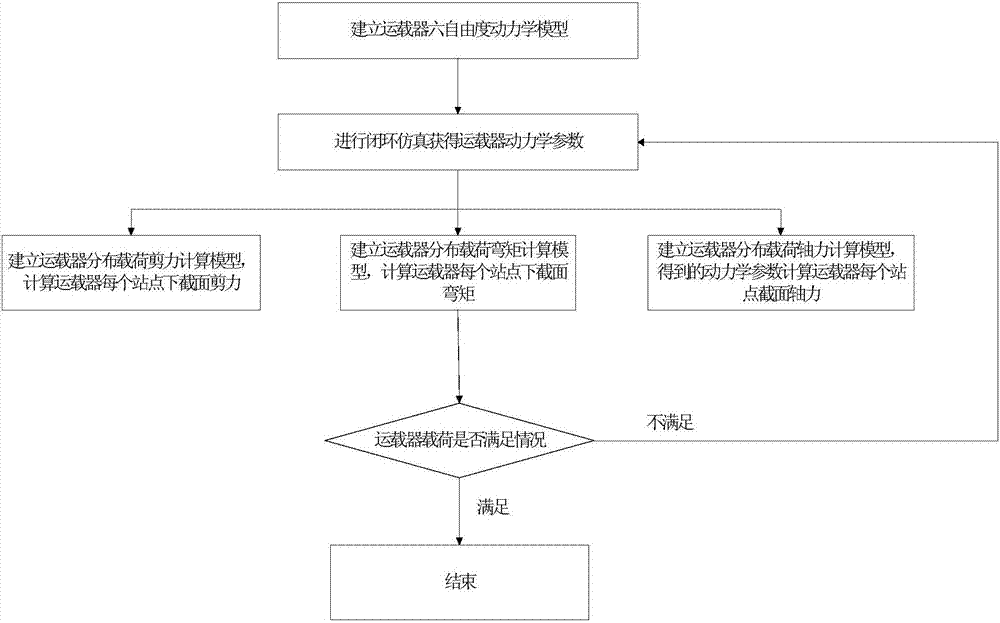

[0050] like figure 1 Shown, the steps of the present invention are as follows:

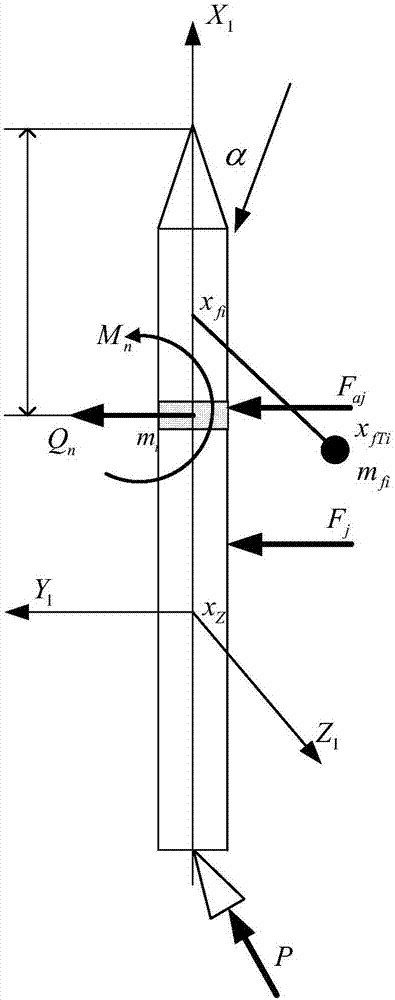

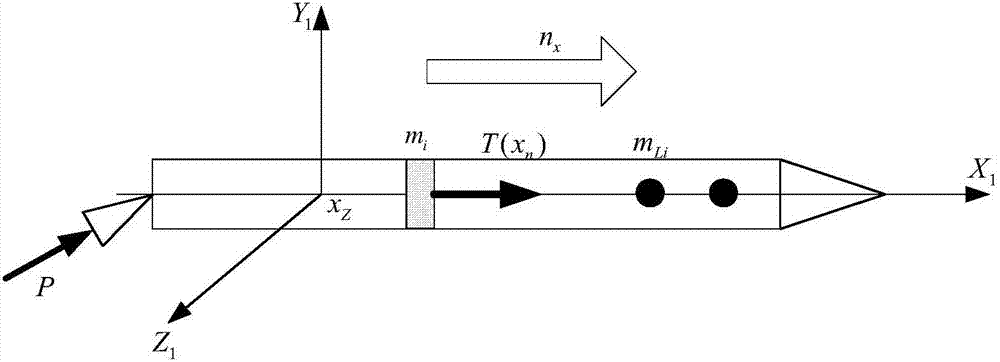

[0051] (1) Establish a six-degree-of-freedom dynamic model for the vehicle.

[0052] The establishment process is as follows:

[0053] First, establish the center-of-mass dynamic equation as follows:

[0054]

[0055]

[0056] is the apparent acceleration of the vehicle coordinate system

[0057] is the transformation matrix from the launch system to the launch system

[0058] V=L T (A 0 ,B 0 ,ω e ,t)V a -ω e ×r

[0059]

[0060] In the formula:

[0061] Acceleration of the center of mass of the vehicle in the launching inertial system; x a ,y a ,z a : The position of the center of mass of the vehicle in the launch inertial coordinate system

[0062] Velocity of the vehicle's center of mass relative to the launch inertial frame.

[0063] is the transformation matrix between the rocket body coordinate system and the launching inertial system; γ, ψ, are the roll a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com