Reflector used for spallation neutron source

A technology of spallation neutron sources and reflectors, applied in the field of reflectors, can solve the problems that reflector structures cannot be compared, achieve long service life, accurate installation and positioning, and realize the effects of remote maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

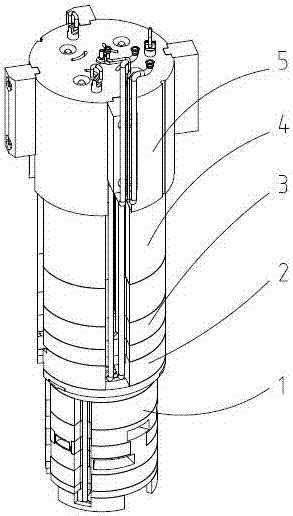

[0044] Such as figure 1 As shown, a reflector for a spallation neutron source, the reflector is in the shape of a stepped cylinder as a whole, mainly including the lower section 1 of the reflector, the connecting ring 2, the middle section of the reflector and the reflector connected by long bolts The upper section 5 and the connecting ring 2 are used to connect the lower section 1 of the reflector and the lower section 3 of the middle section of the reflector.

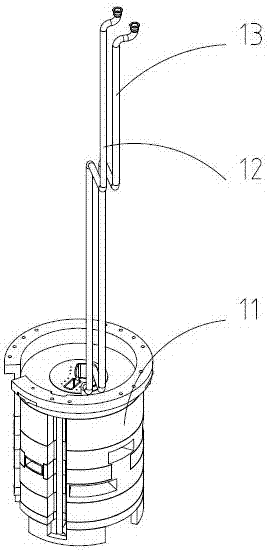

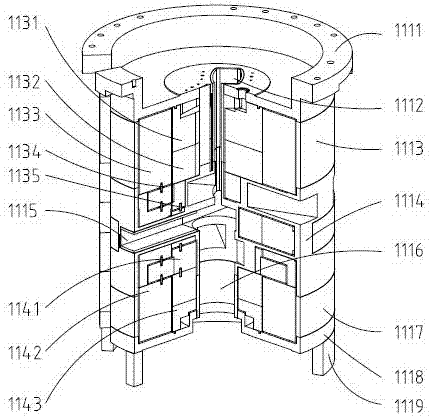

[0045] Such as Figure 2-5 As shown, the overall shape of the lower part of the reflector 1 is a cylindrical structure, mainly including the lower part of the reflector body 11, the lower water inlet pipe 12 and the lower water outlet pipe 13, wherein the lower part of the reflector body 11 mainly includes the outer airtight aluminum container 111 and The lower reflector 114 , the middle reflector 112 and the upper reflector 113 are vertically installed inside the aluminum container 111 from bottom to top.

[0046] ...

Embodiment 1

[0062] Embodiment 1: Real-time monitoring of the temperature of the lower section 1 of the reflector in the reflector used for the spallation neutron source

[0063] In order to monitor the internal temperature and surface temperature of the lower section 1 of the reflector in real time, six thermocouples are installed, two of which are installed inside the aluminum container 111, respectively above the target channel and the proton channel, and the thermocouple wires Pass through the middle of the internal reflector of the aluminum container 111 and lead out from the lower outlet pipe 13. Since the lower outlet pipe 13 is filled with cooling water, the surface of the thermocouple cannot be welded. The present invention uses a ferrule to solve the sealing problem of the outlet point of the thermocouple; That is, the thermocouple wires pass through the ferrule, the fixed end of the ferrule is welded to the lower outlet pipe 13, and the joint part of the ferrule is tightened to c...

Embodiment 2

[0064] Example 2: Remote maintenance of a reflector used for a spallation neutron source

[0065] The design life of the reflector plug-in in the present invention is ten years, and it needs to be disassembled and lifted out after the expiration of the service period. Since the reflector plug-in is a high-radiation component, the whole disassembly and hanging-out process must be operated by remote control; the present invention adopts Special long bolts and hoisting studs realize remote maintenance of reflector inserts.

[0066] First determine the lifting parts and maintenance tools: the reflector insert as a whole includes three sets of M42 long bolts, four in each set, and the length has two specifications of 860mm and 1330mm; the hexagon head size of the long bolts is the standard M42 outer hexagon bolt head size To ensure the versatility of the long bolts, in order to facilitate the remote positioning of the pneumatic wrench, the height of the hexagonal head is increased ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com