Method for carrying out corrosion resistant marking by utilizing ultrafast laser

An ultra-fast laser and anti-corrosion technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of use influence, light, rainy weather, marking area corrosion, etc., and achieve a wide range of materials , good consistency and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

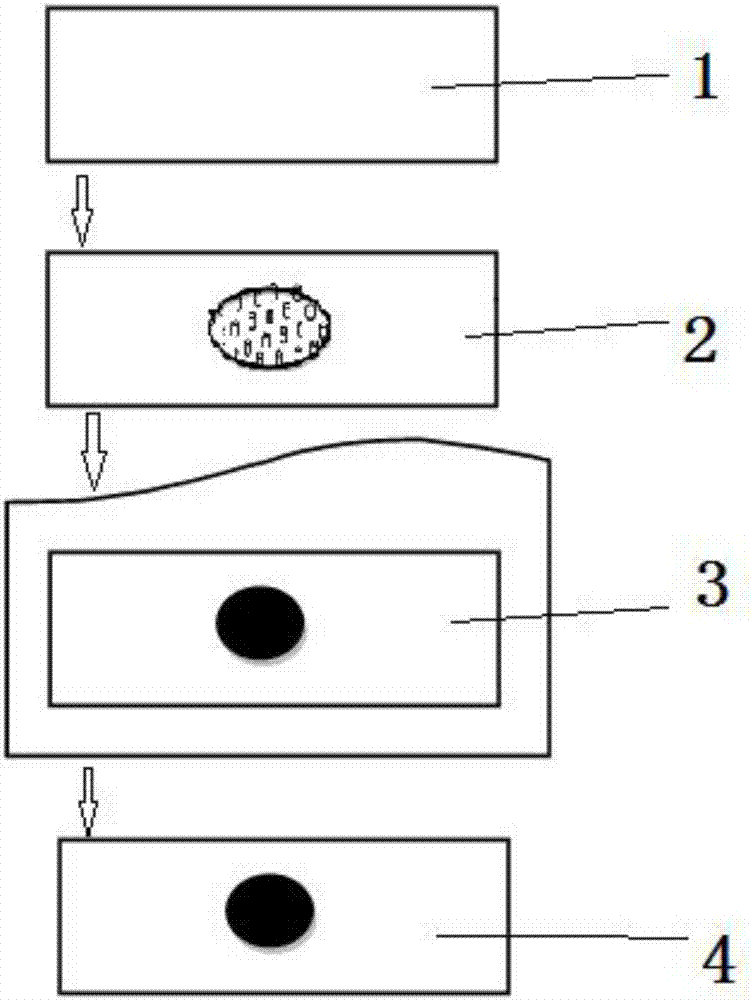

[0019] Embodiment 1 This implementation discloses a method of using laser for anti-corrosion marking. The steps of the method are as follows (the specific flow chart is as follows figure 1 As shown, among them, 1-the workpiece to be processed; 2-the drawing micro-nano structure diagram after laser processing;):

[0020] 1. Place the workpiece to be processed on the processing platform, and the workpiece to be processed is a metal material.

[0021] 2. Draw or import the required logo graphics according to the logo pattern.

[0022] 3. Set the laser focus position and laser processing parameters through the industrial computer, then turn on the laser, and set the laser processing parameters as follows:

[0023] The wavelength of laser processing is 266nm;

[0024] The pulse width is ps / fs level;

[0025] The frequency is below 1MHz;

[0026] The power is below 10W.

[0027] After selecting the processing parameters according to the needs, turn on the laser marking machine ...

Embodiment 2

[0034] Embodiment 2 This implementation discloses a method of using laser for anti-corrosion marking, and the steps of the method are as follows:

[0035] 1. Place the workpiece to be processed on the processing platform, and the workpiece to be processed is an alloy material.

[0036] 2. Draw or import the required logo graphics according to the logo pattern.

[0037] 3. Set the laser focus position and laser processing parameters through the industrial computer, then turn on the laser, and set the laser processing parameters as follows:

[0038] The wavelength of laser processing is 355nm;

[0039] The pulse width is ps / fs level;

[0040] The frequency is below 1MHz;

[0041] The power is below 10W.

[0042] After selecting the processing parameters according to the needs, turn on the laser marking machine to process the workpiece to be processed.

[0043] 4. Form a micro-nano structure on the surface of the material through laser processing, and form the required logo ...

Embodiment 3

[0049] Embodiment 3 This implementation discloses a method of using laser for anti-corrosion marking, and the steps of the method are as follows:

[0050] 1. Place the parts to be processed on the processing platform, such as metals, alloys, and polymer materials.

[0051] 2. Draw or import the required logo graphics according to the logo pattern.

[0052] 3. Set the laser focus position and laser processing parameters through the industrial computer, then turn on the laser, and set the laser processing parameters as follows:

[0053] The wavelength of laser processing is 532nm;

[0054] The pulse width is ps / fs level;

[0055] The frequency is below 1MHz;

[0056] The power is below 10W.

[0057] After selecting the processing parameters according to the needs, turn on the laser marking machine to process the workpiece to be processed.

[0058] 4. Form a micro-nano structure on the surface of the material through laser processing, and form the required logo pattern.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com