Mechanical preheating type 3D printing head

A 3D printer and print head technology, applied in the field of 3D printing technology, can solve problems such as tall models and inability to print out, and achieve the effect of eliminating technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

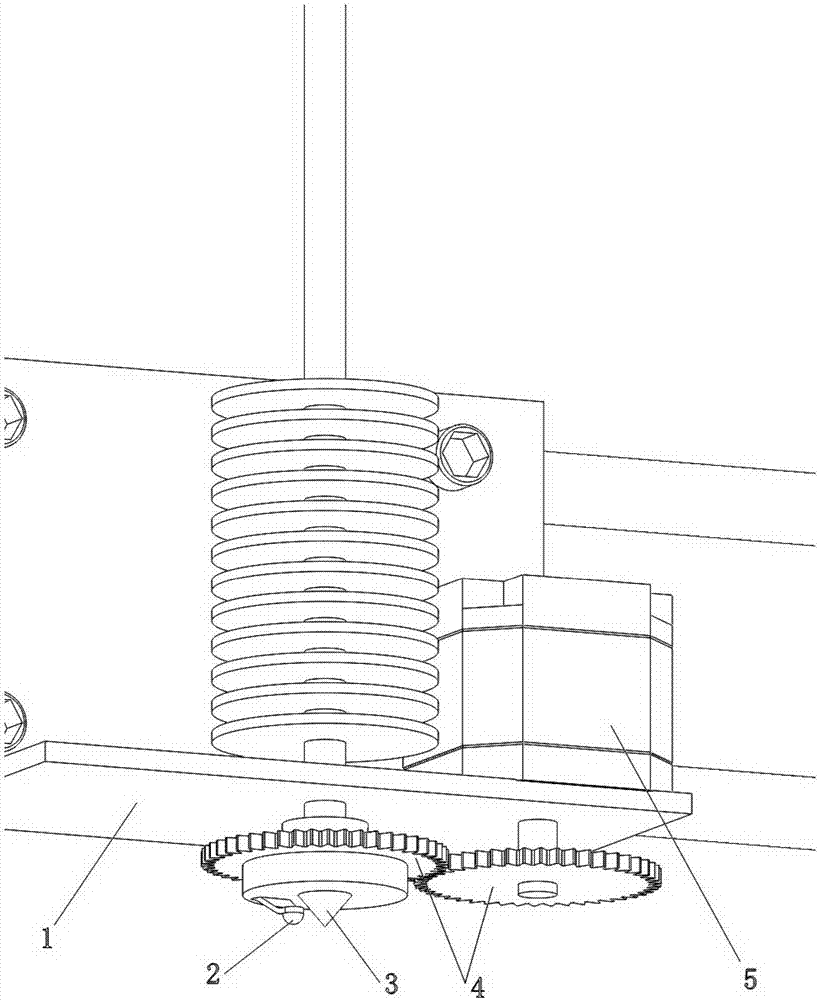

Image

Examples

Embodiment Construction

[0008] The printing material of fused accumulation 3D printing is hot-melt plastic, which is characterized by being heated to a certain temperature and melted and bonded together well, which is the technical basis of fused accumulation 3D printing. However, when the material or one of the materials is below the melting temperature, the two materials cannot be fusion bonded together. Therefore, in fused accumulation 3D printing, to ensure that the printed upper and lower slices can be fused and bonded together, it is necessary to ensure that the surface temperature of the upper slice to be printed by the print head reaches the melting temperature. Only in this way, the upper All slices can be fused together with the current spray ratio, which is a necessary condition for printing out a solid model; in order to make the bonding between adjacent slices stronger and the printed model stronger during fused accumulation 3D printing, the present invention The following technical meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com