Purification and arsenic removal method for zinc hydrometallurgy system

A technology for hydro-smelting zinc and zinc powder, which is applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problem that it cannot better cope with high-arsenic calcine, cannot meet the requirements of electrolysis, and cannot deeply remove arsenic. ions and other problems, to achieve the effect of reducing zinc powder consumption, ensuring stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

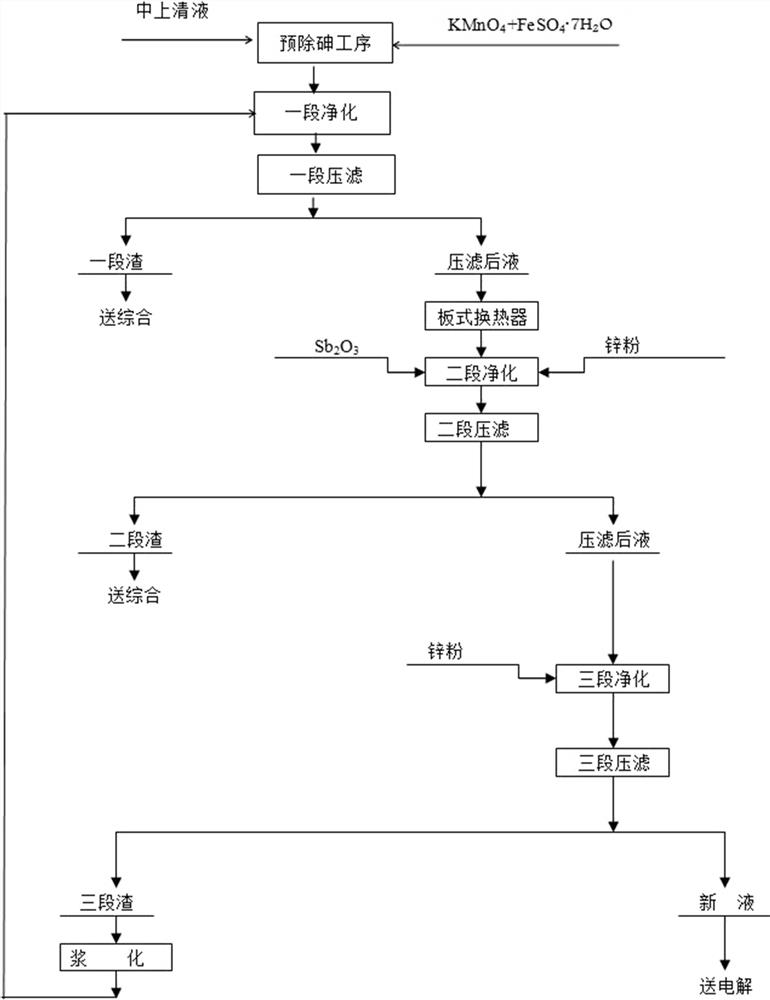

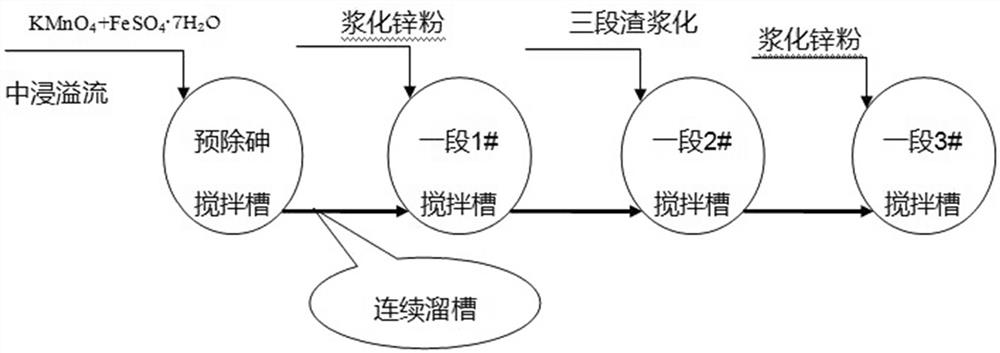

[0048] Example: such as figure 2 As shown, the present invention discloses a method for purifying and removing arsenic in a wet zinc smelting system. The method includes the following steps: (1) A stirring tank is added as a pre-removing arsenic reaction tank before the first-stage purification reaction, and a glass fiber reinforced plastic chute and a first-stage first tank are used at the tank outlet The inlet of the tank is connected with the overflow storage tank by pump and pipeline. (2) Pump the middle immersion overflow into the pre-arsenic removal reaction tank, manually add ferrous sulfate and potassium permanganate, and stir. (3) The ratio of potassium permanganate to ferrous sulfate is 2:1, and the amount of potassium permanganate added is 1.7 times the arsenic content in the solution. (4) Add zinc powder in a 1# stirring tank, the amount of zinc powder added is 80% of the total copper content of the solution. (5) Add the third-stage slag slurry solution to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com