Movable ground box

A mobile, ground wire technology, applied in the directions of internal accessories and external accessories, can solve the problems of high labor intensity, low work efficiency, time-consuming and laborious operation, etc., and achieve the effect of reducing labor intensity, convenient access, and flexible and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

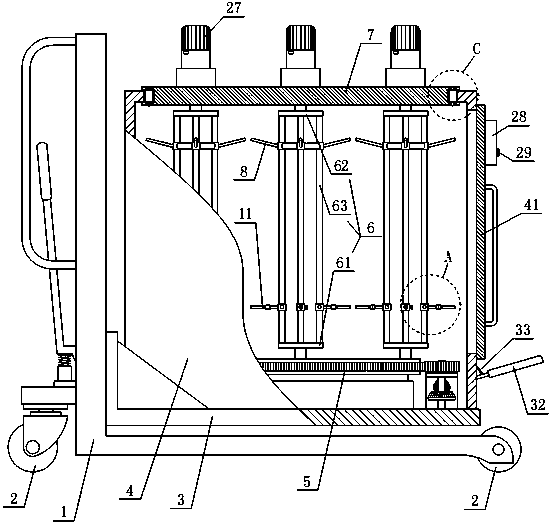

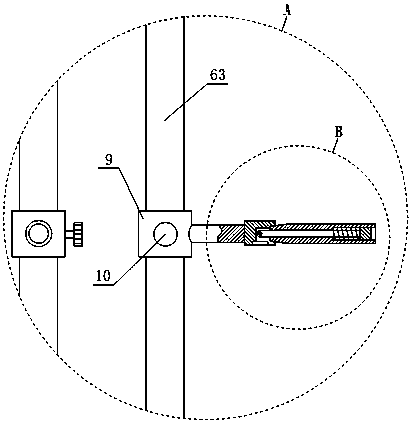

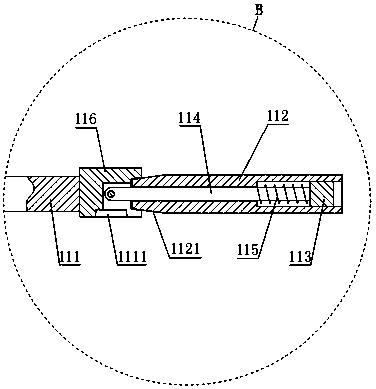

[0030]Referring to the accompanying drawings, the movable ground box of the present invention includes an L-shaped underframe 1, the bottom of the underframe 1 is provided with rollers 2, and the underframe 1 is equipped with a lifting base 3 driven by a hydraulic mechanism located at its rear. , the lifting base 3 is provided with a box body 4, and the front portion of the box body 4 is provided with an opening and a box door 41 is installed on the opening. A turntable 5 is mounted on the bottom of the box body 4, and the bottom of one side wall of the box body 4 is rotated to be equipped with a transverse transmission shaft 17. The extended end of the ratchet sleeve 30 is connected with a pedal 32, the pedal 32 is connected with an extension spring 33, and the top of the extension spring 33 is connected on the outer side wall of the casing. A plurality of vertically arranged turrets 6 are installed at intervals on the circumference of the top surface of the turntable 5 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com