Leakage-proof bottle cap

A bottle cap, extension surface technology, applied in the directions of closing, packaging, transportation and packaging, can solve problems such as opening and tightening troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

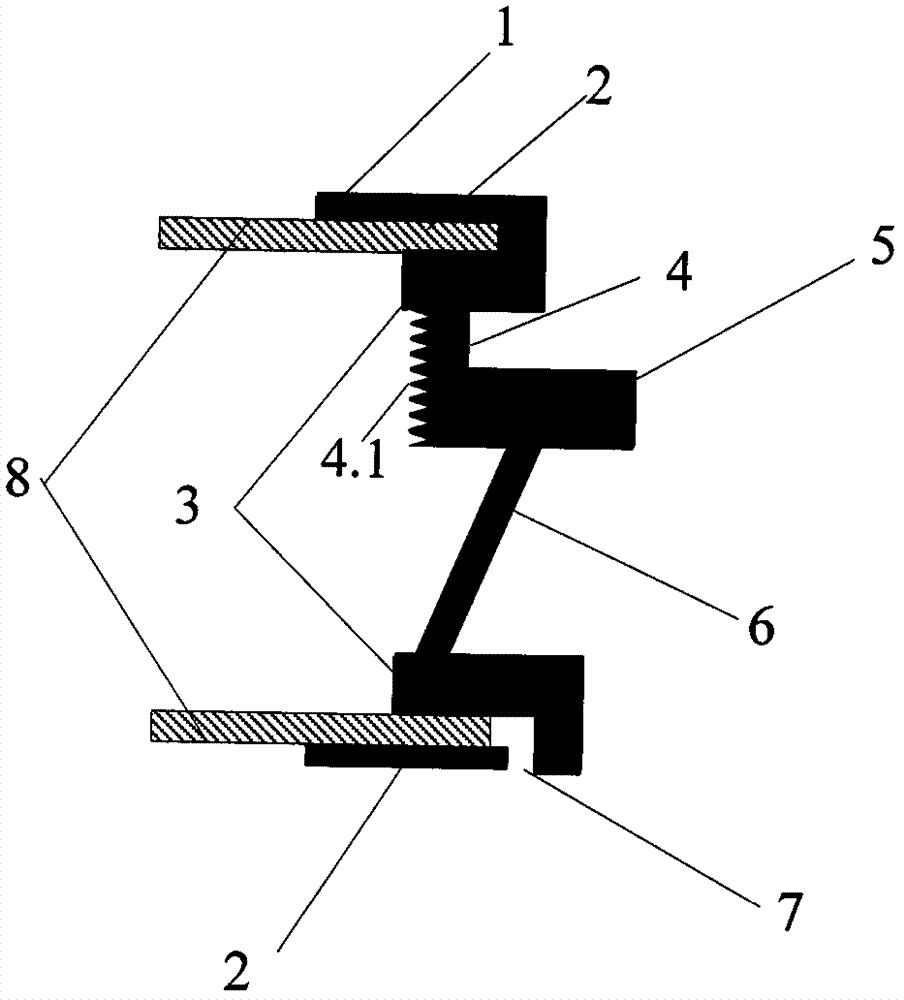

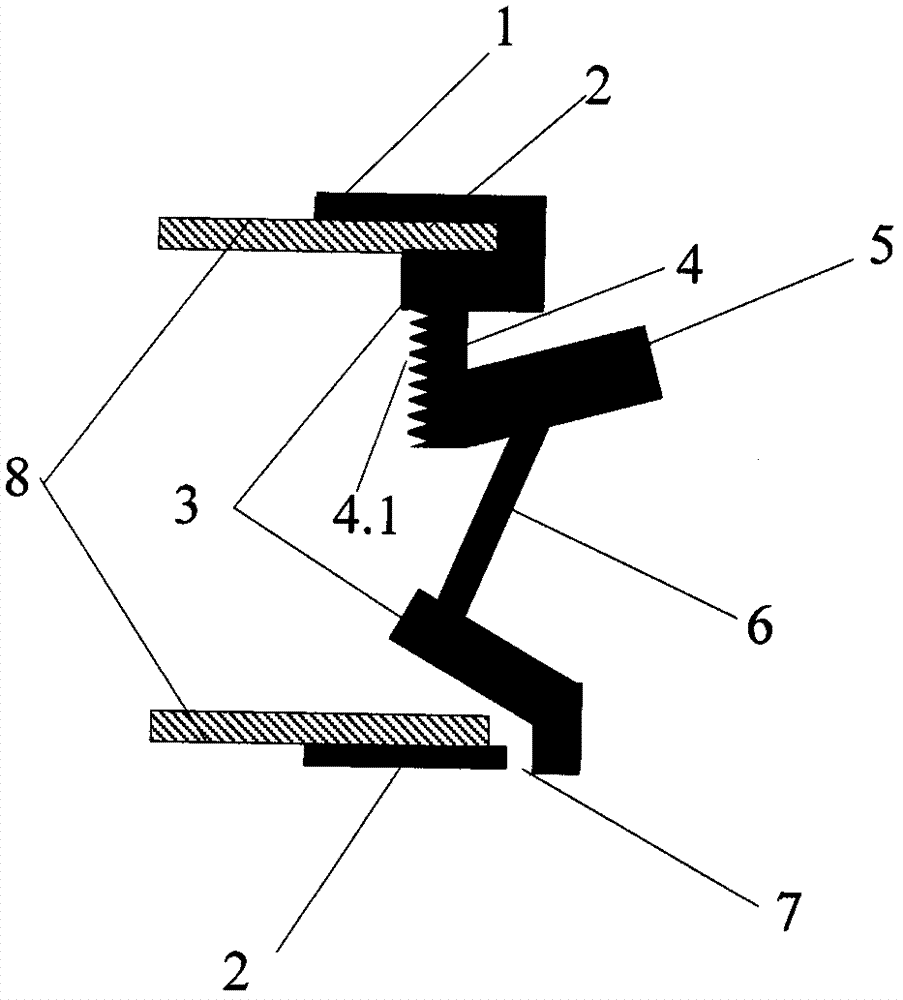

[0025] A leak-proof bottle cap of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

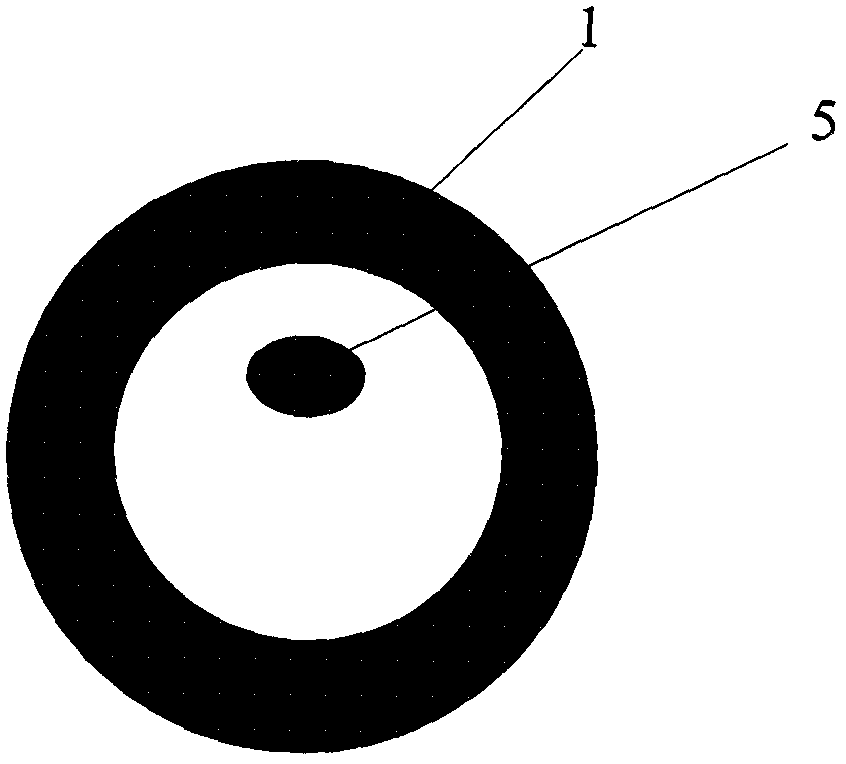

[0026] Such as figure 1 As shown, a leak-proof bottle cap of the present invention includes the outer wall 1 of the bottle cap, and is characterized in that it is also provided with: a bottle mouth engaging groove 2 for engaging with the bottle mouth 8; Wall 3 is used to tighten the bottle mouth 8 from the inside to prevent side leakage; the bottle cap extension surface 6 is connected to the inner stop wall 3 of the bottle cap, which can pull the inner stop wall 3 of the bottle cap away from the bottle mouth 8; toggle switch 5 is connected with the extension surface 6 of the bottle cap, and can pull the extension surface 6 of the bottle cap; the compression surface 4 of the bottle cap is connected with the toggle switch 5, and is used to provide restoring force for the toggle switch 5, so that the extension surface 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com