High-efficiency garbage leach ate treatment process

A landfill leachate and treatment process technology, which is applied in the field of high-efficiency landfill leachate treatment process, can solve the problems of large area, complex management, high operating costs, etc., and achieve the effects of effective utilization, guaranteed water output, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

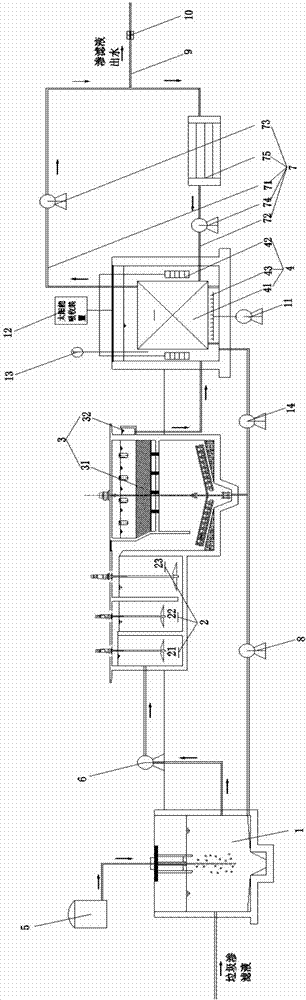

[0027] This embodiment provides a high-efficiency landfill leachate treatment process and a device used in the process.

[0028] The devices used in the above process include: a mixing adjustment tank 1, a dosing tank 2, an inclined tube sedimentation tank 3, and a membrane distillation reaction tank 4 connected in sequence.

[0029] The internal space of the mixing regulating tank 1 is connected with an ozone generator 5, the water outlet of the mixing regulating tank 1 is connected with the lifting pump 6 through a water pipe, and the lifting pump 6 is connected with the water inlet of the dosing tank 2 through a water pipe.

[0030] The dosing pool 2 includes a PAC dosing area 21, a magnetic powder dosing area 22, and a PAM dosing area 23 that are sequentially connected.

[0031] An inclined tube group 31 is provided above the inside of the inclined tube sedimentation tank 3, and the inclined tube group includes a plurality of inclined tubes with a length of 1-1.2m and an inclinatio...

Embodiment 2

[0042] This embodiment provides a high-efficiency landfill leachate treatment process. The equipment used is the same as that of the first embodiment. The specific processing steps are basically the same as those of the first embodiment. The difference lies in:

[0043] The above-mentioned garbage leachate from the Hubei landfill was treated. During the test operation, the water temperature (T) of the distillation membrane reaction tank was 45-55℃, the cooling system temperature T was maintained at 10-15℃, and the pH was 6.5-7.5. The device runs continuously, the initial membrane flux is 15.0-20.0L / m 2 h. Ozone adjustment pool O 3 Concentration 0.4mg / L; PAC dosage is 25.0mg / L, PAM dosage is 0.8mg / L, F 3 O 4 The dosage is 5mg / L.

[0044] The test effluent result is: effluent COD cr The concentration is 80.0mg / L, BOD 5 The concentration is 16.0mg / L, NH 3 -N concentration is 20.0mg / L, SS concentration is 11.0mg / L. The treatment effect is basically the same as the first embodiment.

Embodiment 3

[0046] This embodiment provides a high-efficiency landfill leachate treatment process. The equipment used is the same as that of the first embodiment. The specific processing steps are basically the same as those of the first embodiment. The difference lies in:

[0047] The above-mentioned garbage leachate from the Hubei landfill was treated. During the test operation, the water temperature (T) of the distillation membrane reaction tank was 48-58℃, the cooling system temperature T was maintained at 12-17℃, and the pH was 6.0-7.0. The device runs continuously, the initial membrane flux is 15.0-20.0L / m 2 h. Ozone adjustment pool O 3 Concentration 0.8mg / L; PAC dosage is 30.0mg / L, PAM dosage is 1.2mg / L, F 3 O 4 The dosage is 3mg / L.

[0048] The test effluent result is: effluent COD cr The concentration is 83.0mg / L, BOD 5 The concentration is 15.0mg / L, NH 3 -N concentration is 23.0mg / L, SS concentration is 12.0mg / L. The treatment effect is basically the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com