Shield structure tunnel curve section duct piece pre-assembly type selection design method based on BIM technology

A technology of shield tunneling and design method, which is applied in the direction of tunnel, tunnel lining, design optimization/simulation, etc., can solve the problems of difficult selection of segment wedge shape, difficult segment assembly, large accumulated error, etc. The effect of reducing construction loss and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

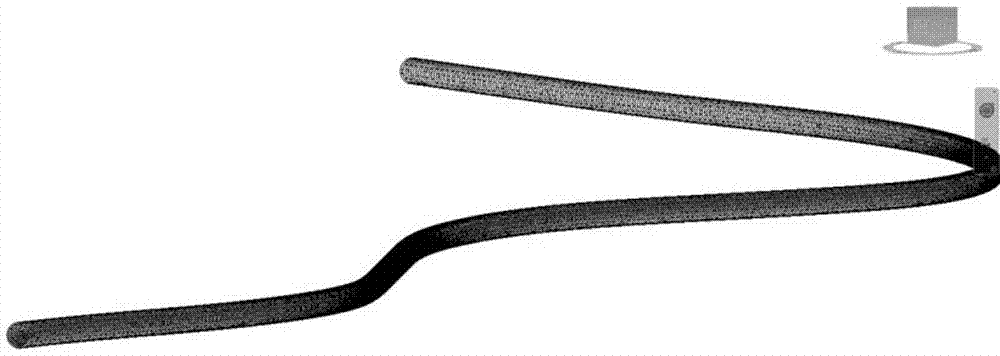

[0026] A BIM-based technology-based design method for the pre-assembly and selection of shield tunnel segment segments in curved sections, comprising the following steps: Step S1: extracting line plane and longitudinal section data to generate a three-dimensional space curve for the centerline of the curved section;

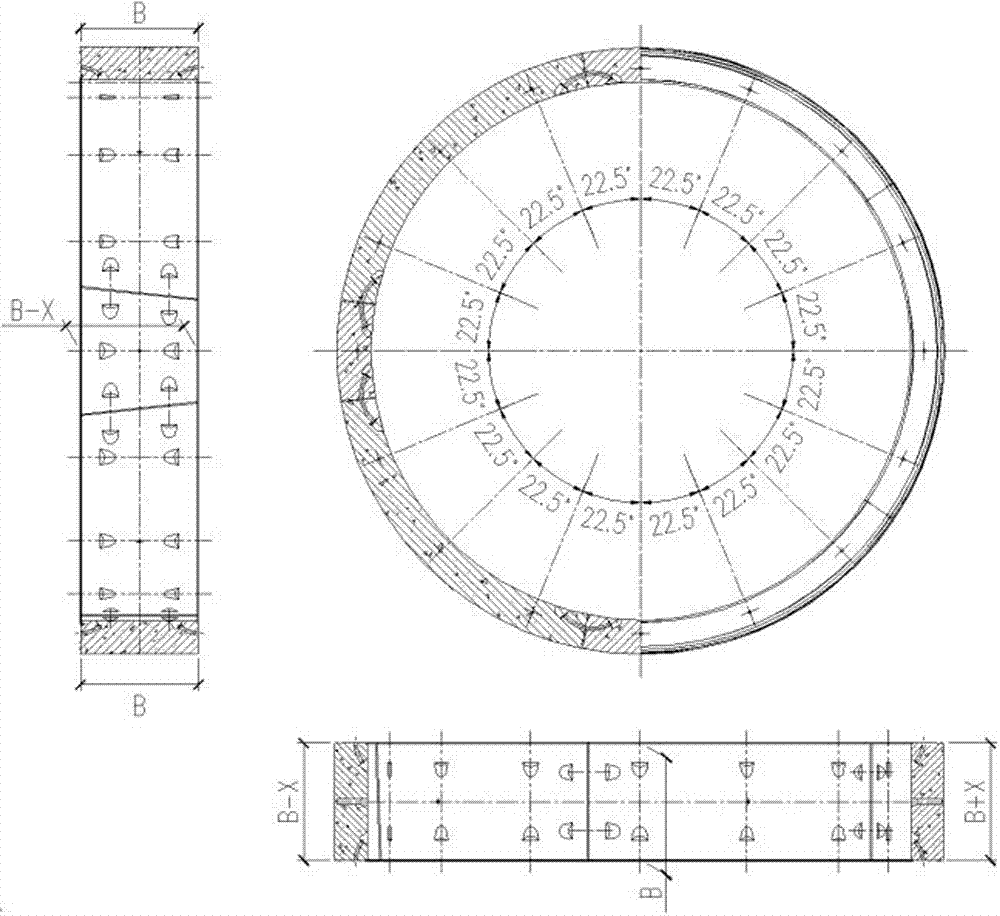

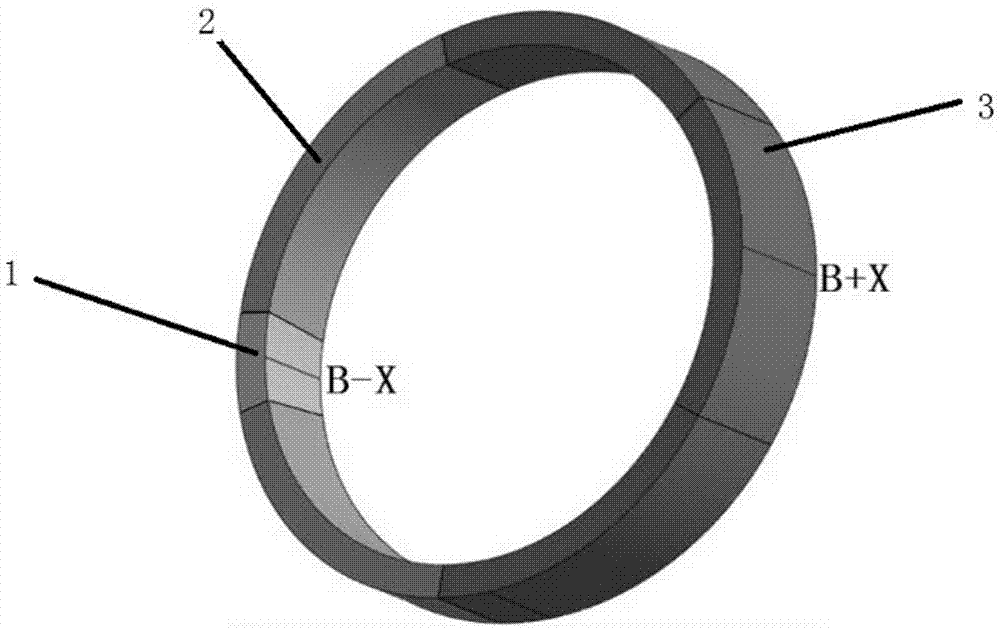

[0027] Step S2: Establish a three-dimensional model of the single-ring segment according to the design drawing;

[0028] Step S3: Carry out line pre-assembly along the three-dimensional space curve of the center line of the shield tunnel curve section;

[0029] Step S4: export the layout diagram of each ring segment of the line;

[0030] Step S5: Install the physical components according to the pre-assembled layout diagram.

[0031] Further, in this embodiment, in step S1, the three-dimensional coordinates of the centerlin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap