A kind of piston suitable for circular pendulum reciprocating motion

A technology of reciprocating motion and piston, which is applied in the direction of machines/engines, pump components, liquid displacement machinery, etc., can solve problems such as limiting the working efficiency of compressors and affecting the shock absorption effect of air springs, and achieves good air tightness and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

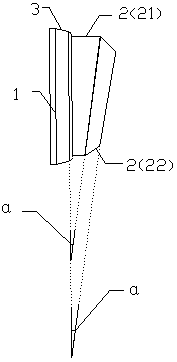

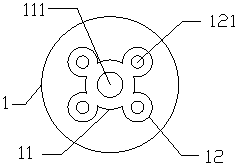

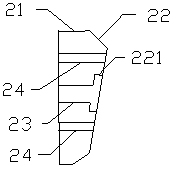

[0024] A piston suitable for reciprocating motion of a circular pendulum, such as Figure 1~3 As shown, it includes a piston head 1, a piston skirt 2 and a piston ring 3. The piston head 1 is mechanically connected to the piston skirt 2. Specifically, the bolt passes through the second bolt through hole inside the second spherical groove 12 provided. 121 is connected with the threaded through hole 24, and the piston head 1 is mechanically connected with the piston skirt 2. At this time, the first bolt through hole 111 inside the first spherical groove 12 is connected with the third bolt through hole 23, and the piston ring 3 Wrapping the gap outside the piston head 1 and mechanically connecting the piston head 1 and the piston skirt 2 , the piston skirt 2 includes a connecting section 21 at the front end and a working section 22 at the rear end.

[0025] In the above, in order to make the piston fully fit in the circular cylinder, the working section 22 and the connecting sect...

Embodiment 2

[0033] This embodiment is a specific improvement of Embodiment 1. According to the diameter of the annular cylinder of the air compressor and the size of its internal piston assembly, the included angle α is jointly determined to be 10°. During the specific working process, the piston can be in the annular cylinder and the inner wall Under the condition of complete fit, the circular pendulum motion is performed. During the circular pendulum motion, the piston ring 3 itself has a lubricating function, so the air compressor using the piston in this embodiment is an oil-free lubricating air compressor.

Embodiment 3

[0035] This embodiment is a specific improvement of Embodiment 1. According to the diameter of the annular cylinder of the air compressor and the size of its internal piston assembly, the included angle α is jointly determined to be 13°. During the specific working process, the piston can be in the annular cylinder and the inner wall Under the condition of complete fit, the circular pendulum motion is performed. During the circular pendulum motion, the piston ring 3 itself has a lubricating function, so the air compressor using the piston in this embodiment is an oil-free lubricating air compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com