Thickness detection device for variable-thickness sheet stamping parts

A technology for thickness detection and stamping parts, which is applied in the field of thickness detection devices for stamping parts of variable-thickness plates, can solve the problems of large fluctuation of measurement accuracy, high labor intensity of workers, and difficulty in realizing industrialization, and achieves high measurement efficiency and reduced labor intensity. , the effect of avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

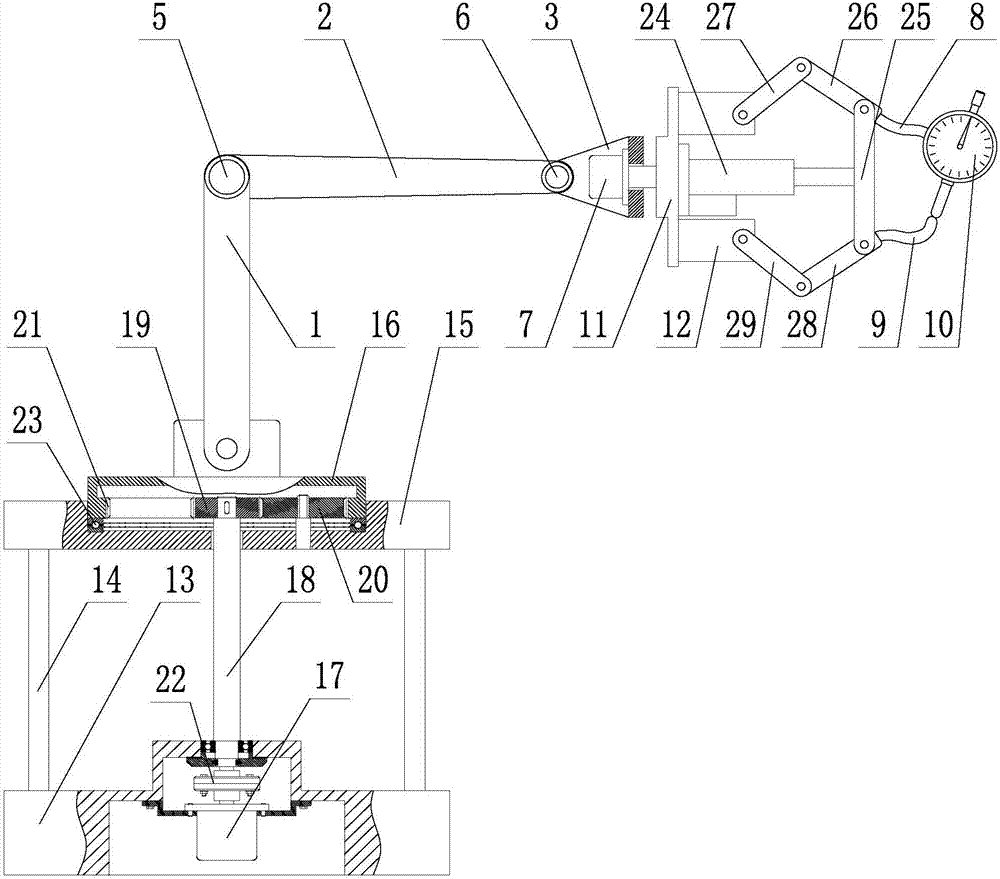

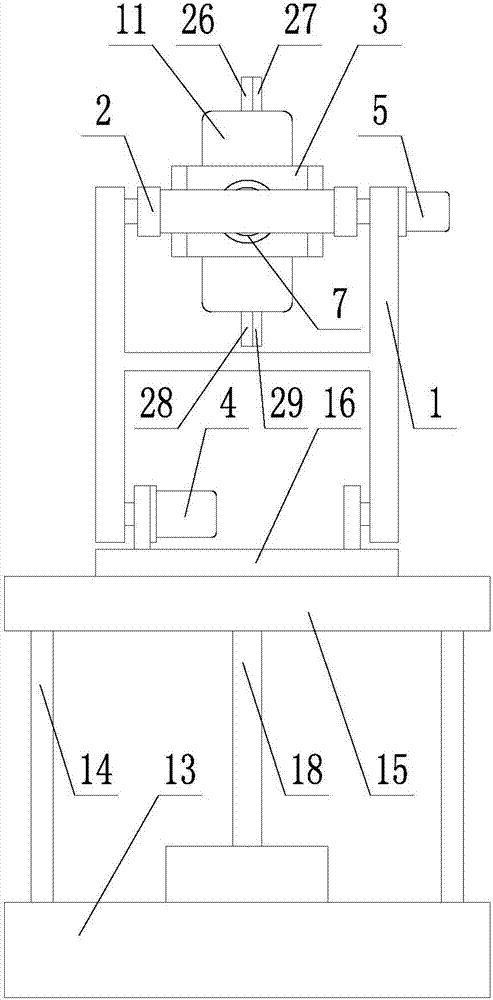

[0017] Such as figure 1 , 2 As shown, a thickness detection device for sheet metal stamping parts with variable thickness includes a rotary base, a large arm 1, a small arm 2, a wrist 3 and a claw; one end of the large arm 1 is hinged on the rotary base, and A boom drive motor 4 for driving the swing of the boom 1 is arranged at the hinge point; Forearm drive motor 5; the other end of the forearm 2 is hinged to one end of the wrist 3, and a wrist drive motor 6 for driving the swing of the wrist 3 is provided at the hinge point; the other end of the wrist 3 is fixed with a claw Rotary drive motor 7, described claw root 11 is fixedly connected with the motor shaft of claw rotary drive motor 7; Two measuring fingers are arranged at the front end of described claw palm 12, respectively denoted as main measuring finger 8 and Auxiliary m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com