Method used for laboratory simulation of automobile coating B pillar chromatic aberration

A B-pillar and automobile technology, applied in the field of simulation of automobile B-pillar painting, can solve the problems of difficult spraying effects and obvious differences, and achieve the effects of improved color appearance, improved effectiveness and authenticity, and accurate operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to the preferred embodiments, those skilled in the art should understand that the technical solutions of the invention can be modified or equivalently replaced , without departing from the spirit and scope of the technical solution of the present invention, all of which shall be covered by the claims of the present invention.

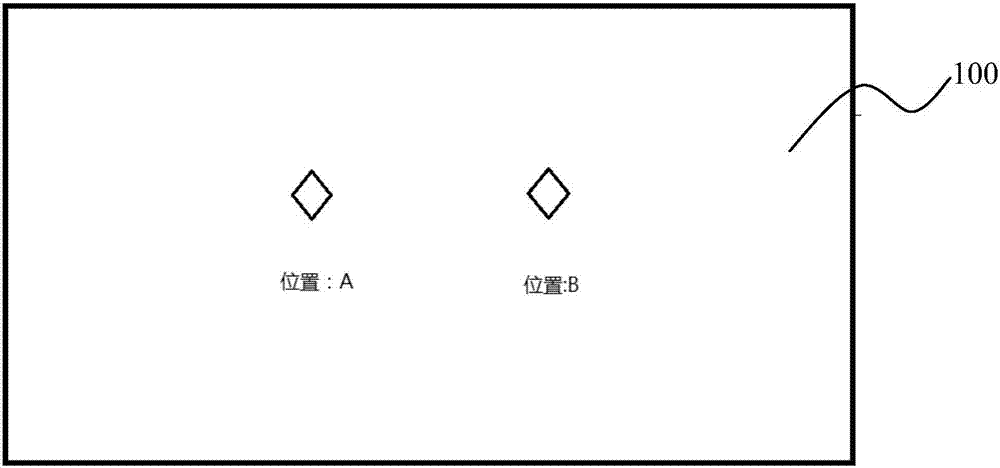

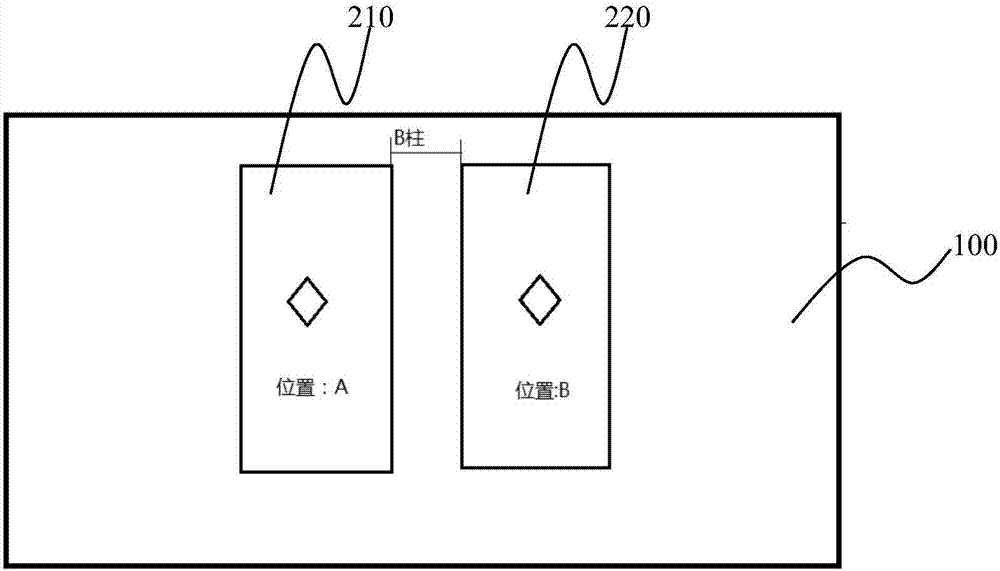

[0020] figure 1 It is a schematic diagram of the arrangement of each fixing piece in the method for simulating the chromatic aberration of the B-pillar of automobile painting in the present invention, figure 2 It is a schematic diagram of the arrangement of each plate in the method for simulating the chromati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com