Position sensor and changeable capacitance module of same

A capacitive component and variable technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of insignificant change of capacitance value, poor displacement sensitivity, and inability to be controlled by users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

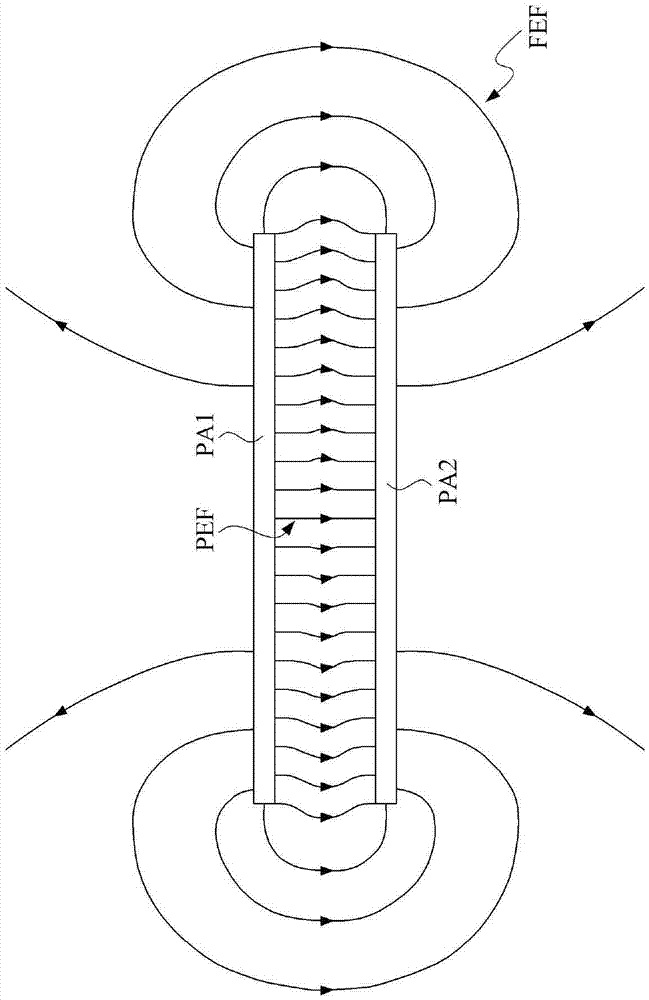

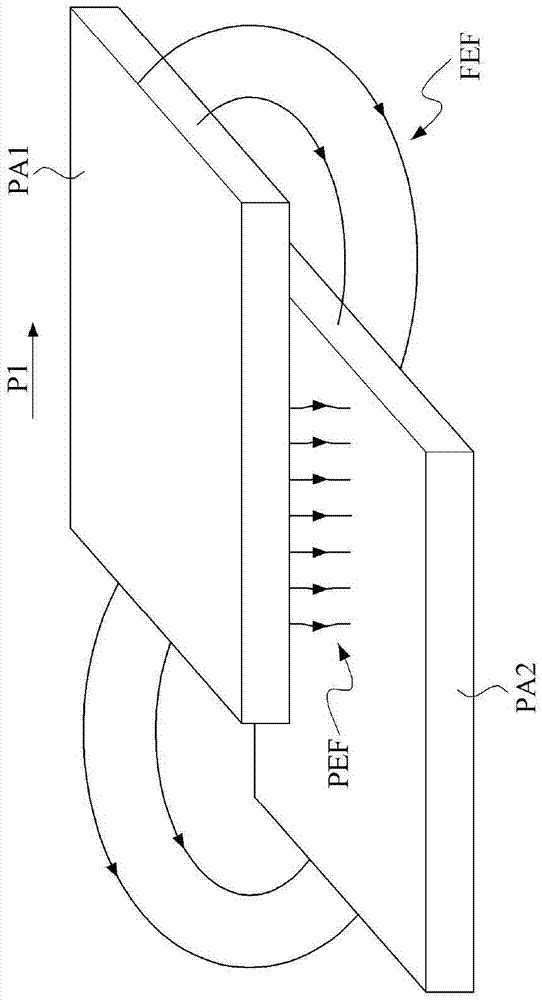

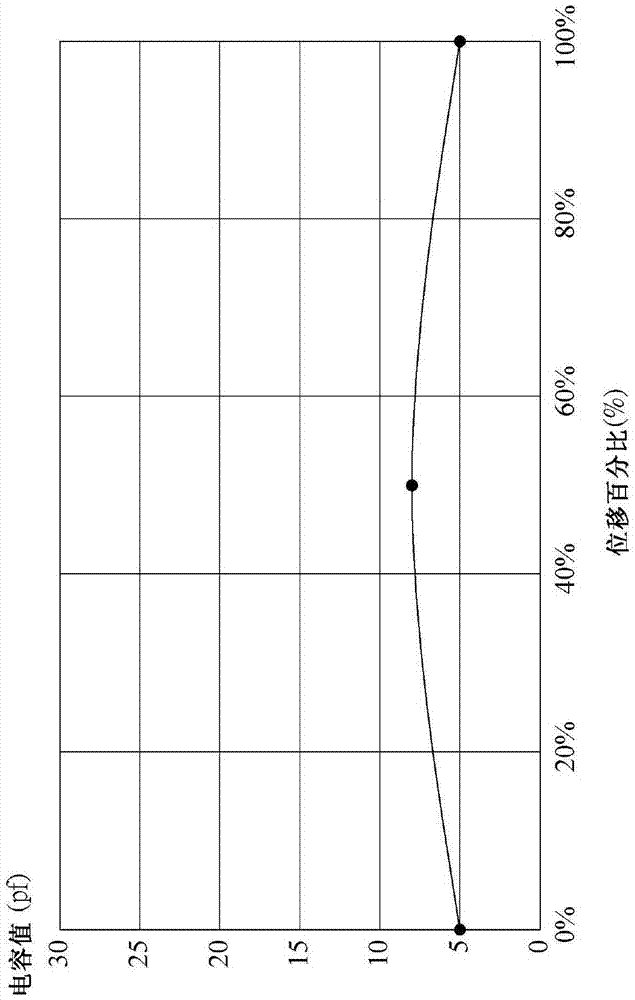

[0072] see Figure 4 to Figure 7 , Figure 4 A three-dimensional exploded schematic diagram showing a position sensor provided by a preferred embodiment of the present invention; Figure 5 A perspective exploded schematic diagram showing the variable capacitance component provided by the preferred embodiment of the present invention; Figure 6 A schematic plan view showing the variable capacitance component provided by the preferred embodiment of the present invention; Figure 7 A schematic circuit diagram of a capacitive sensing circuit provided by a preferred embodiment of the present invention is shown.

[0073] As shown in the figure, a position sensor 100 includes a variable capacitance component 1 , a circuit board 2 , a movable carrier 3 and a casing 4 .

[0074] The variable capacitance device 1 includes a substrate 11 and a dielectric cover 12 . The substrate 11 includes a substrate body 111 , a ground electrode 112 , and two power electrodes 113 and 114 .

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com