Strong coupling between elements and ultra-wide adjustable range active frequency selective surface

A frequency-selective surface and strong coupling technology, applied to electrical components, circuits, waveguide devices, etc., can solve the problems that the resonant frequency and bandwidth cannot be changed, and cannot adapt to the changeable electromagnetic environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

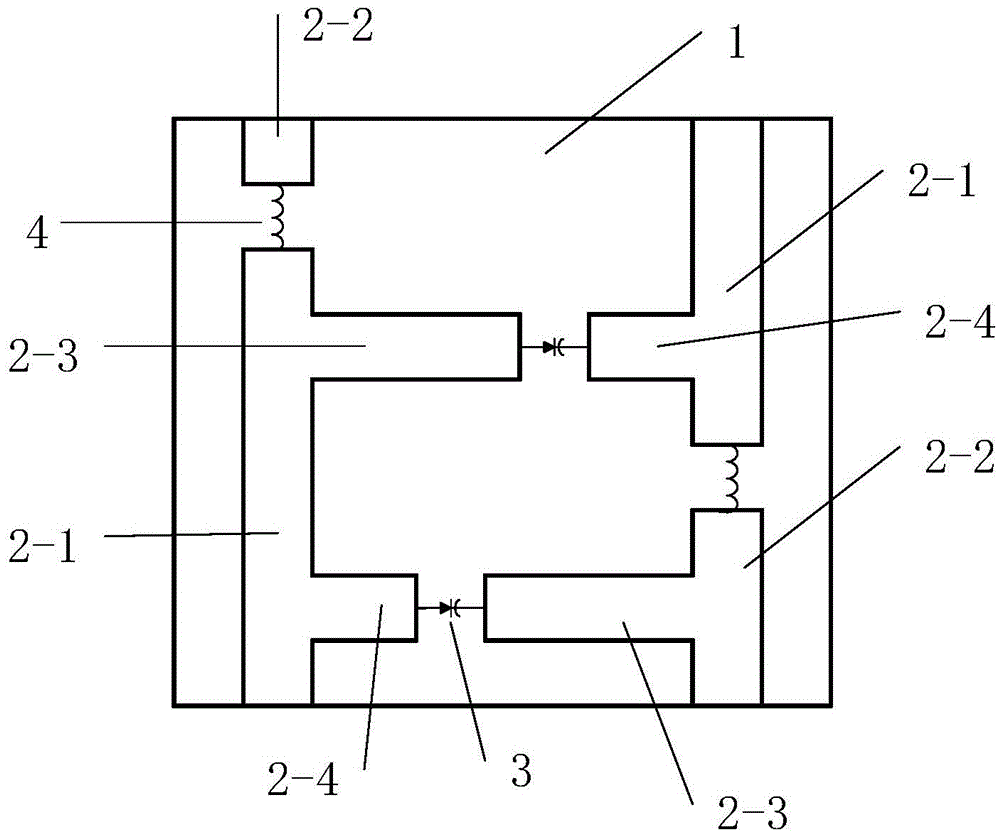

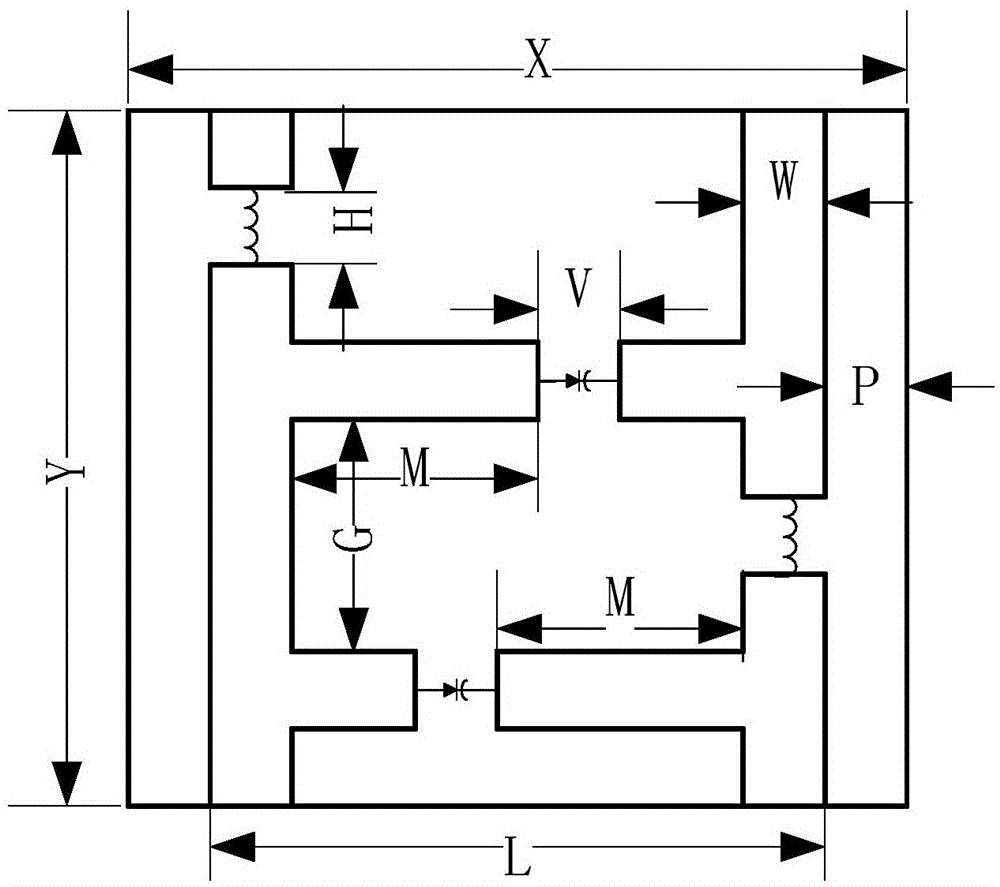

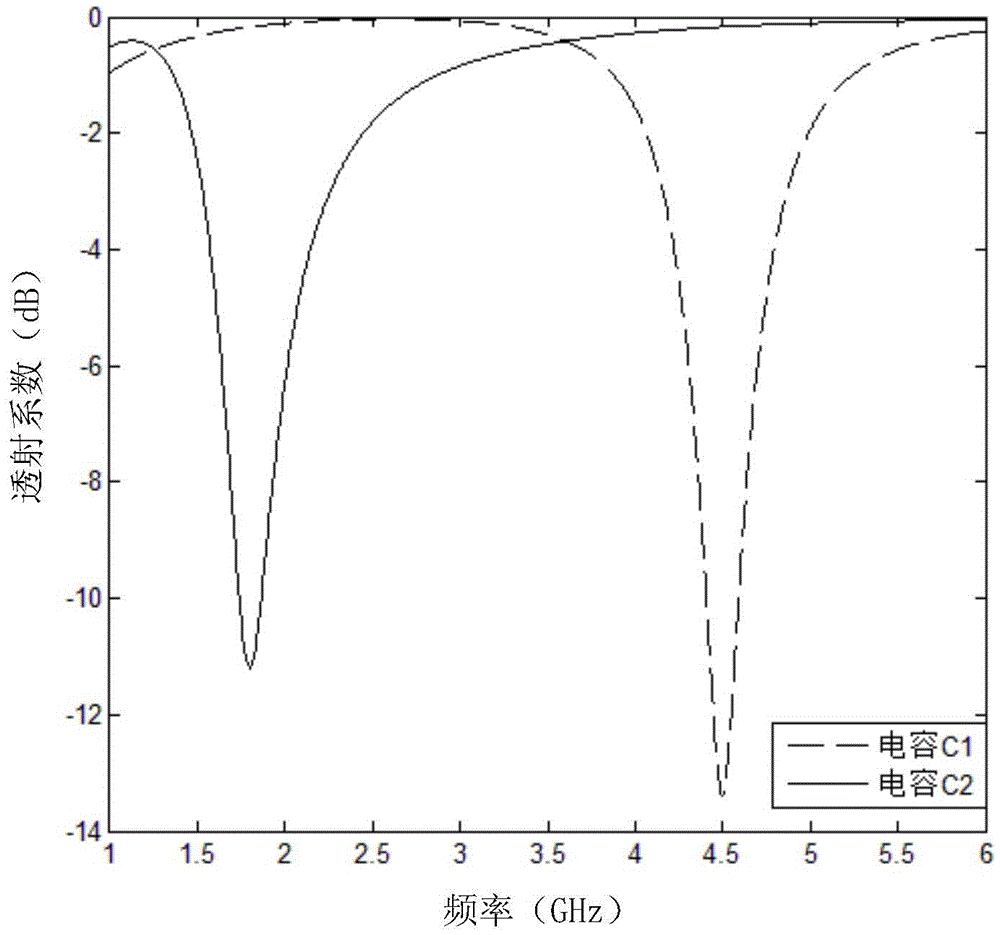

[0015] see Figure 1~4 , the embodiment of the present invention is provided with dielectric plate 1, metal layer, varactor diode 3 and inductor 4; Metal layer, varactor diode 3 and inductor 4 are arranged on the front of dielectric plate 1, and described metal layer is vertical strip metal layer , load two horizontal strip metal layers of different lengths in the horizontal direction of the vertical strip metal layer, and the distance between the vertical strip metal layer and the two horizontal strip metal layers of different lengths is two strips of different lengths Half of the long strip metal layer in equal horizontal strip metal layers; two horizontal strip metal layers of different lengths are connected by varactor diodes, the vertical strip metal layers are connected by inductors, and the vertical strip metal layers are connected with The horizontal strip meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com