Independent winding and continuous pole-equipped permanent magnet motor

A technology for permanent magnet motors and windings, applied in magnetic circuits, synchronous machines, electrical components, etc., can solve the problems of complex processing and assembly technology, large amount of permanent magnets, etc., and achieve easy cooling, reduced amount of permanent magnets, and simple winding technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

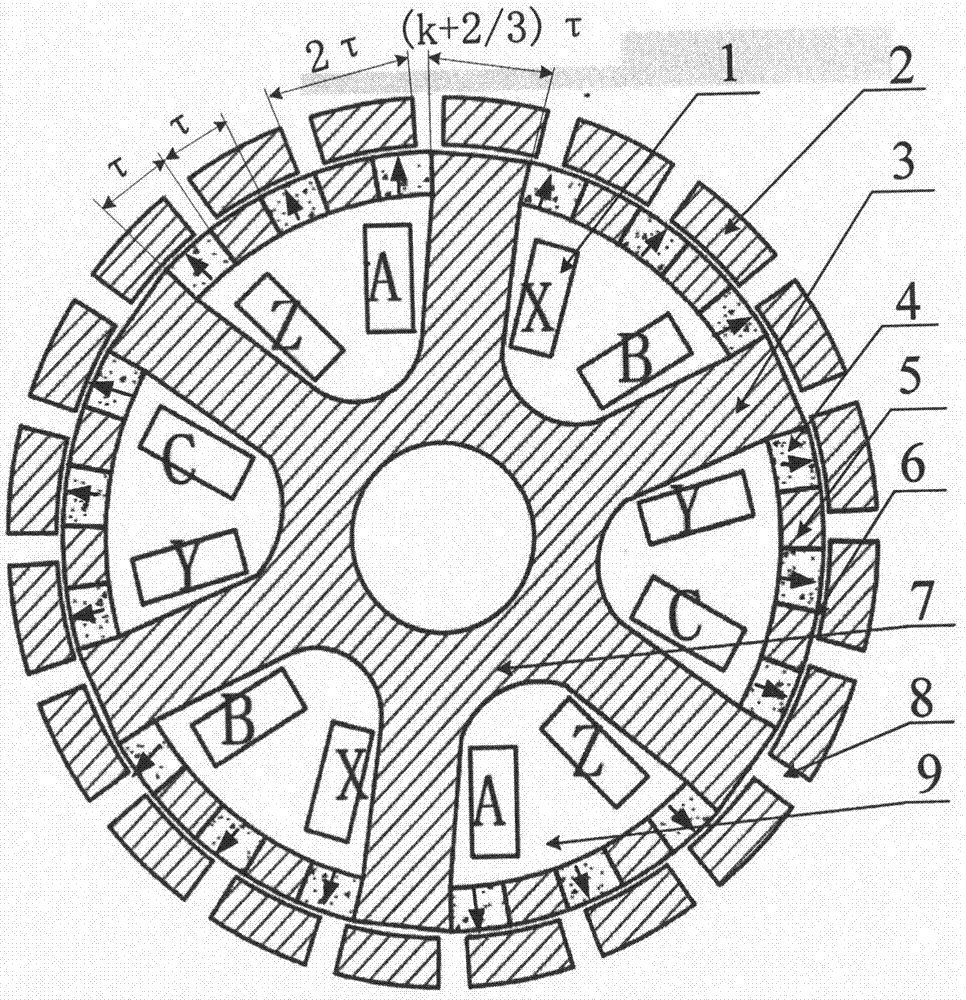

[0021] Such as figure 1 As shown, this embodiment is a three-phase external rotor independent winding continuous pole permanent magnet motor. It includes stator assembly, rotor assembly and air gap. The stator assembly consists of the armature core, armature windings and permanent magnets. The armature core includes large teeth 3, small teeth 5 and armature core yoke 7 structures. The large teeth 3 of the armature core and the yoke 7 form Q (Q=3k, k is an integer) large slots 9, and the armature winding 1 is arranged in the slots. The formed large groove 9 opening positions are provided with permanent magnets 4 and small teeth 5 arrays, and the permanent magnets 4 and small teeth 5 iron core blocks are arranged alternately, and the magnetization direction of all permanent magnets 4 is outward along the radial direction (or both Inward), the number of permanent magnet blocks is N (N=2I+1, I is an integer), the number of small teeth 5 is (N-1), and the position near the armat...

Embodiment approach 2

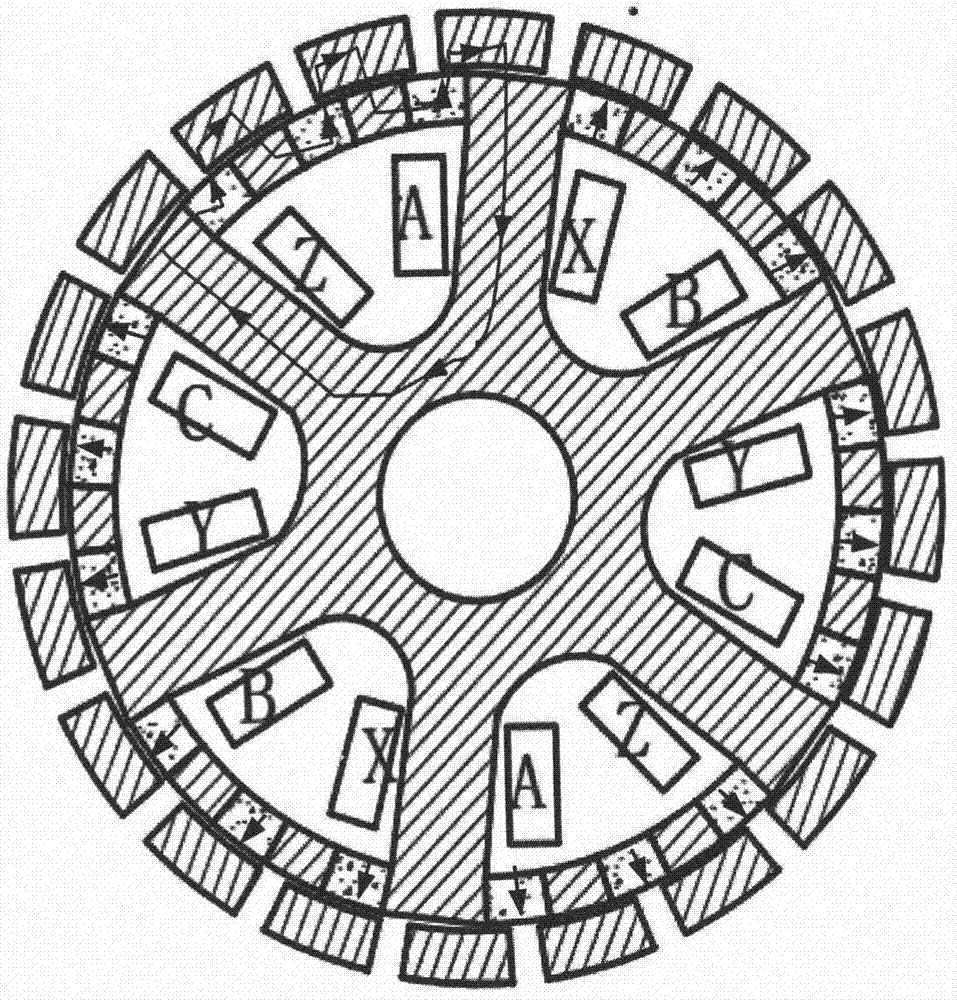

[0027] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that the discrete rotor core 2 is fixed by a sleeve 10, and the sleeve is made of a non-magnetic material.

Embodiment approach 3

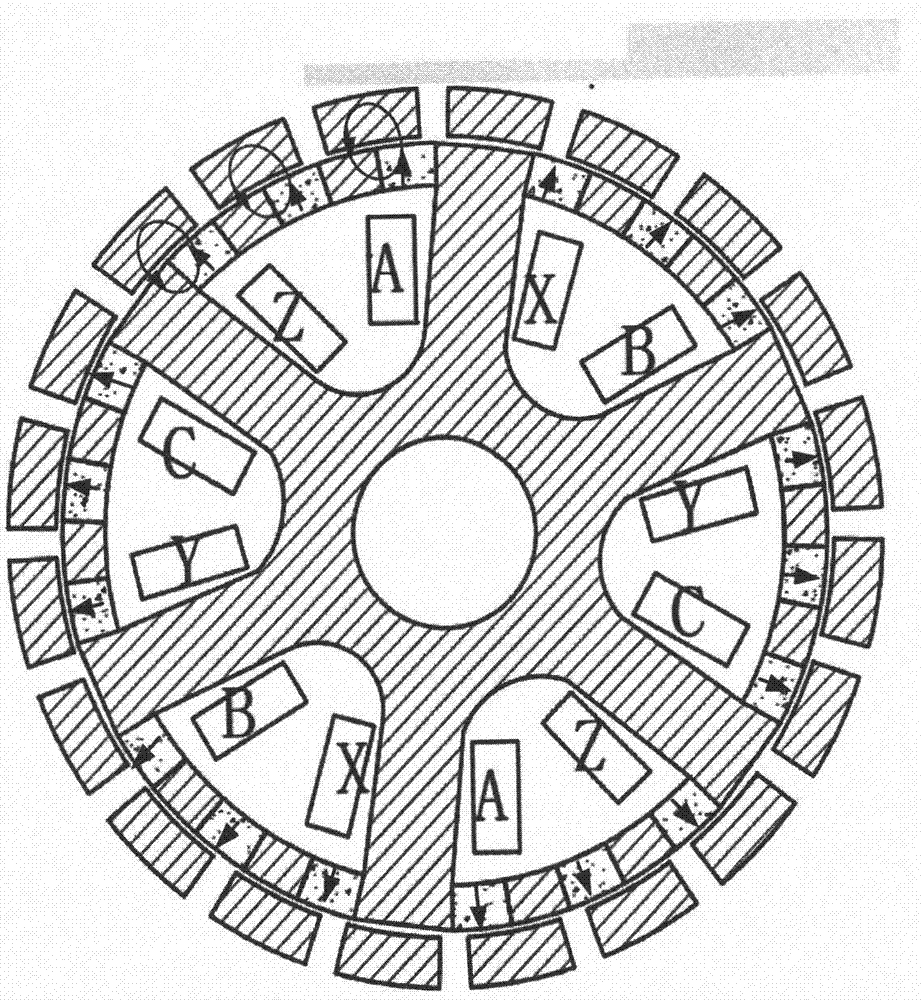

[0029] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that the independent winding continuous pole permanent magnet motor adopts the inner rotor structure scheme. The armature winding 1-1, armature core large teeth 3-1, small teeth 5-1, and armature core yoke 7-1 are located on the outer circle of the motor, and the opening direction of the large slot 9 is along the direction of decreasing radius. The rotor core 2-1 and the gap 8-1 are located in the inner circle of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com