Surface protection film for optics with spacer

A surface protection film, optical technology, used in chemical instruments and methods, film/sheet release liners, film/sheet adhesives, etc., can solve product defects, poor wettability, and poor adhesion and other problems, to achieve the effect of less influence of pollution and excellent peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

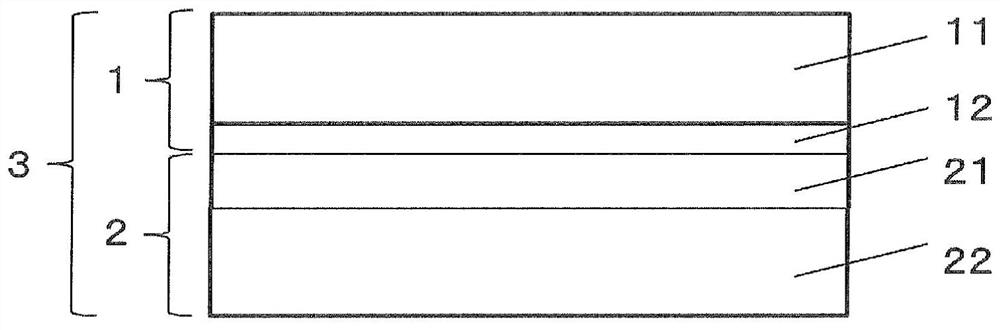

Image

Examples

preparation example Construction

[0140]

[0141] The above-mentioned (meth)acrylic polymer (A1) solution (about 35% by weight) was diluted to 29% by weight with ethyl acetate, and 100 parts by weight (solid content) of the (meth)acrylic polymer relative to the solution , 4 parts by weight of an isocyanurate body of hexamethylene diisocyanate (manufactured by Nippon Polyurethane Industry Co., Ltd., CORONATE HX), and dioctyltin laurate (manufactured by Tokyo Fine Chemicals, EMBILIZER OL-1) as a tin-based catalyst were added. 0.015 parts by weight and 0.69 parts by weight of acetylacetone, which is a compound that undergoes keto-enol tautomerization, were mixed and stirred for about 1 minute at around 25° C. to prepare an adhesive composition (1).

[0142]

[0143] Dissolve 100 parts by weight of a butyral resin (manufactured by Sekisui Chemical Industry Co., Ltd., S-lec KW-10) in 900 parts by weight of xylene (manufactured by Taiyo Chemical Industry Co., Ltd., Kishrol), and then add octadecyl isocyanate. (m...

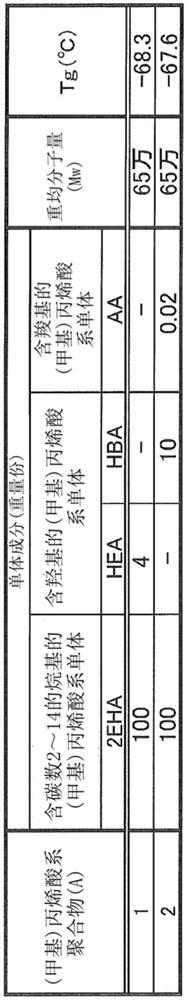

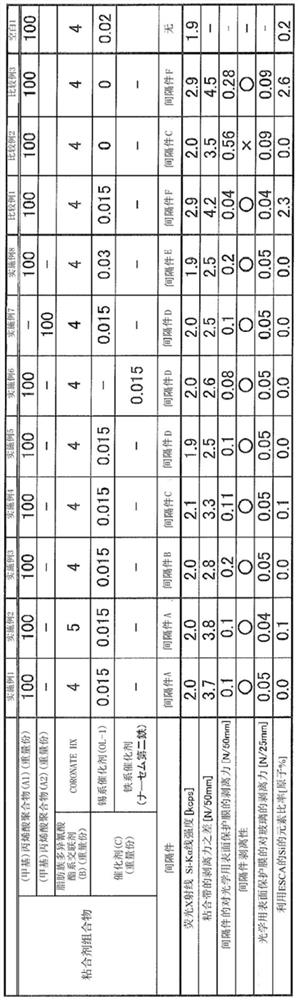

Embodiment 2~8、 comparative example 1~3

[0156]

[0157] As shown in Tables 1 and 2, Examples 2 to 8 and The surface protection film for optics with a spacer of Comparative Examples 1-3. As Blank 1, an optical surface protection film not using a spacer was produced. In addition, as an iron catalyst, tris(acetylacetonate)iron (manufactured by Nippon Chemical Industry Co., Ltd., trade name "Naesem 2nd iron") was used.

[0158]

[0159] Hereinafter, specific compounding amounts and measurement and evaluation methods are described, and the results are described in Tables 1 and 2.

[0160]

[0161] The weight average molecular weight of the produced polymer was measured by GPC (gel permeation chromatography). Conditions are shown below.

[0162] Device: Tosoh Corporation, HLC-8220GPC

[0163] Sample column: manufactured by Tosoh Corporation, TSK guard column Super HZ-H (1 piece) + TSK gel Super HZM-H (2 pieces)

[0164] Reference column: manufactured by Tosohsha, TSK gel Super H-RC (1 piece)

[0165] Flow: 0.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com