Dissimilar pipe joints under high temperature, high pressure transients and under cyclic loading

A pipe joint, heterogeneous technology, applied in the direction of pipe/pipe joint/fitting, flange connection, engine cooling, etc., can solve the problem of reducing life expectancy and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

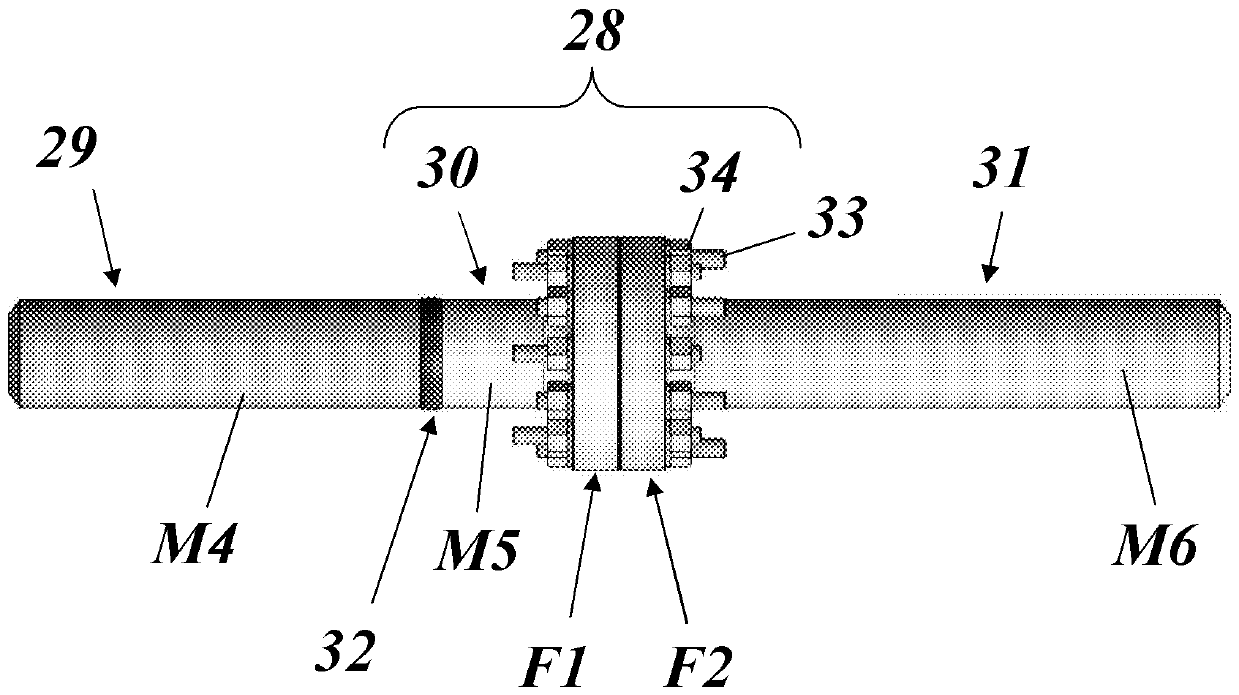

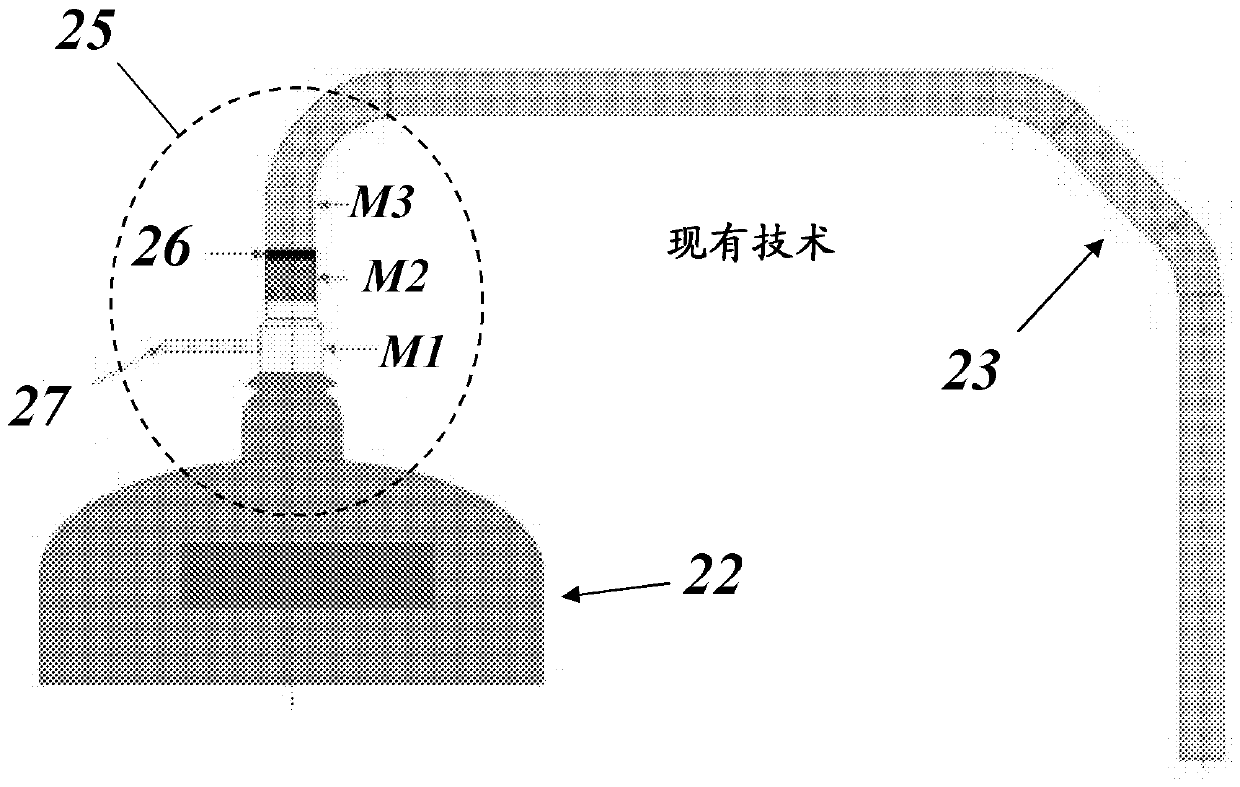

[0036] The problems of connecting stainless steel pipe sections and ferritic steel pipe sections in pipes preferably used in combined cycle power plants are:

[0037] Optimization of CTE (coefficient of thermal expansion) mismatch

[0038] · Achievement of operating pressure and temperature ratings

[0039] · Transient conditions with sharp ups and downs during device start-up

[0040] · Consideration of creep, fatigue and their interaction

[0041] · Lifespan and permissible cycle times

[0042] ·Lifetime free maintenance - not disturbed by the operating system

[0043] · No mixed welds on site

[0044] ·External force and moment

[0045] · Facilitate on-site replacement of existing layout

[0046] ·ASME and PED certified.

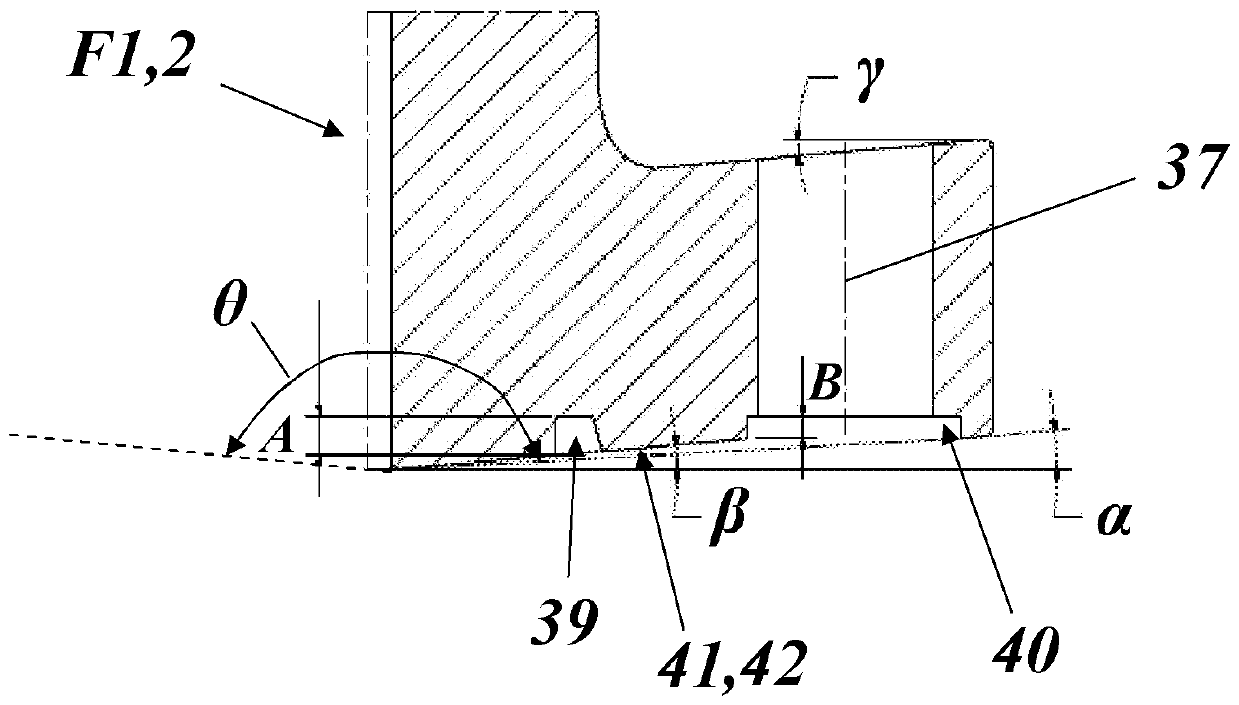

[0047] According to the invention, the dissimilar metal joining joint, which takes into account the different mechanical properties of the materials involved, is used in itself to provide a critical material transition between joining surfaces with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com