Solar battery and solar battery module

A technology of solar cells and electrodes, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as battery warping, increased stress, and electrode peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

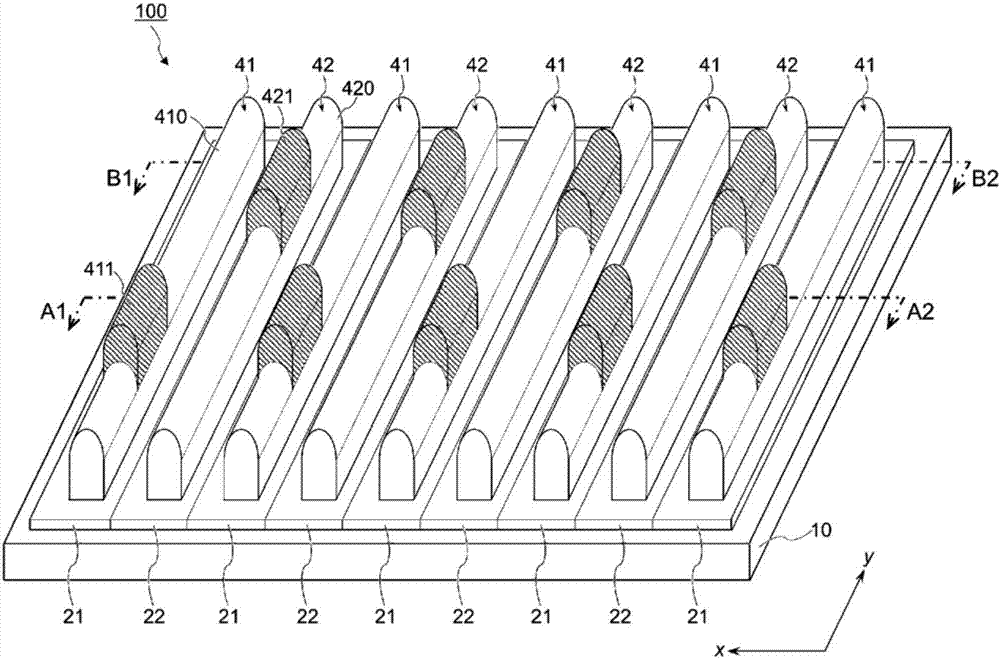

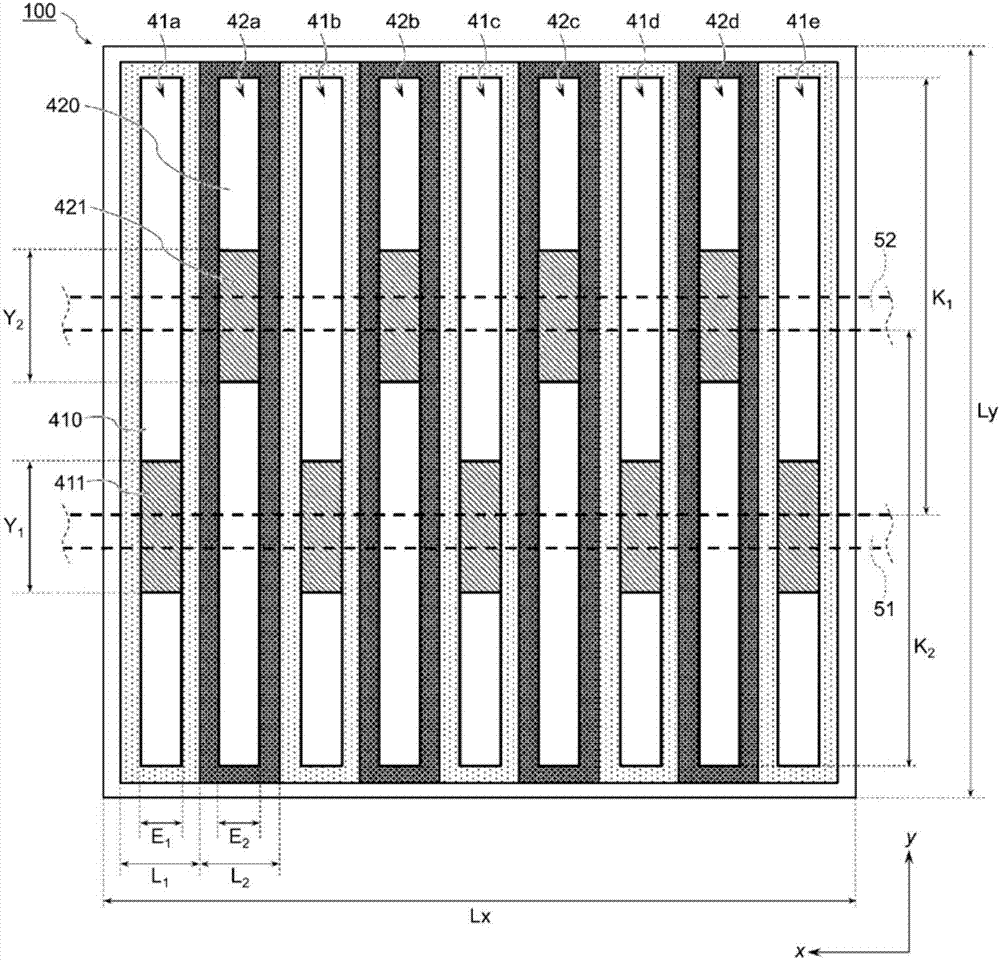

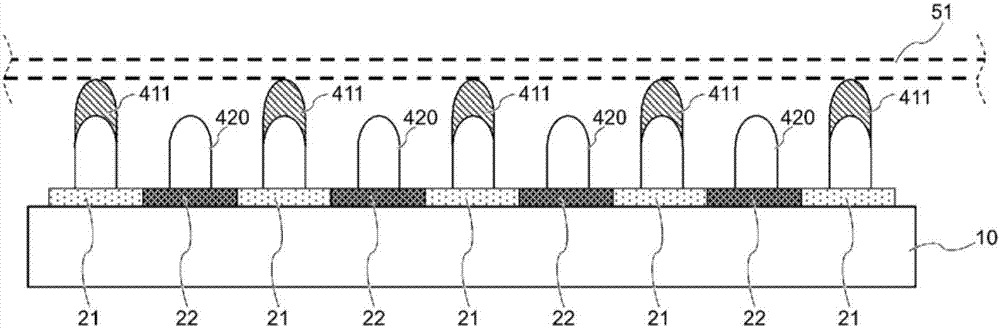

[0045] figure 1 It is a schematic perspective view of a back junction type solar cell according to one embodiment of the present invention. figure 2 yes figure 1 The top view of the upper side (the back side of the solar cell). Figure 3A yes figure 1 A sectional view at line A1-A2 of Figure 3B yes figure 1 Sectional view at line B1-B2. exist figure 2 , Figure 3A as well as Figure 3B In , the state in which the wiring members 51 and 52 are connected to the electrodes of the solar cell is indicated by a dotted line.

[0046] The solar cell 100 is on the back side of the semiconductor substrate 10 ( figure 1 The surface on the upper side) is provided with a first conductivity type layer 21 and a second conductivity type layer 22 . A first electrode 41 is provided on the first conductivity type layer 21 , and a second electrode 42 is provided on the second conductivity type layer 22 . The first electrode 41 and the second electrode 42 are separated and insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com