Preparation method for green tea with delicate fragrance

A technology for green tea and fragrance, which is applied in the field of preparation of fragrance-flavored green tea, can solve the problems of high unfavorable energy, cannot achieve continuous tea production, and save, and achieves the effects of strong fragrance and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The technical scheme of the present embodiment is: a kind of preparation method of delicate fragrance type green tea, comprises the following steps:

[0030] 1) Picking of fresh leaves: Choose a sunny day with an ambient temperature of 18-22°C and no dew in the environment, at an altitude above 1,000 meters, and pick one bud and one leaf or one bud and two leaves for the first development; the picked fresh leaves should be ventilated. Equipment loading and transfer;

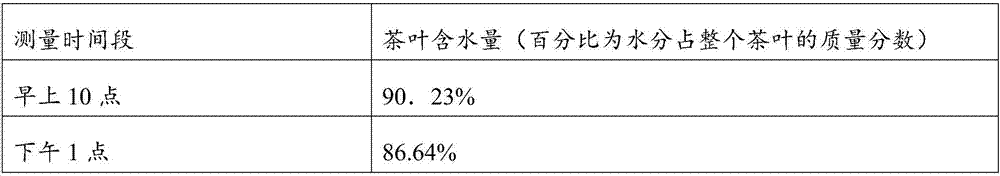

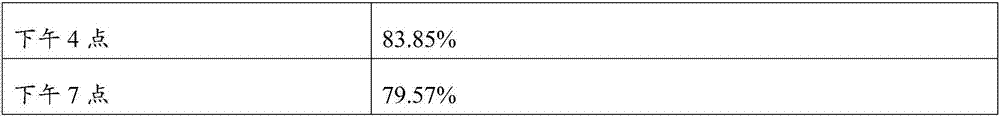

[0031] 2) Greening of fresh leaves: transfer the picked fresh leaves to a cool and ventilated airing place, spread the fresh leaves and let them wither naturally, the thickness of the spread is 2-4 cm, and detect the tea leaves during the process of natural withering The water content of the tea leaves should be recorded; when the tea leaves lose 8% to 12% of the water content, stop the spreading process;

[0032] 3) De-enzyming of tea leaves: the de-enzyming treatment of the green tea leaves after being ...

Embodiment 2

[0048] On the basis of Embodiment 1, the technical solution of this embodiment is: the altitude in the step 1) is 1200-1500 meters.

[0049] The inventors have found that when the altitude is 1200-1300 meters, the content of aromatic substances in the tea leaves is higher than that of tea leaves grown at other altitudes.

Embodiment 3

[0051] On the basis of embodiment one, the technical solution of the present embodiment is: the sunny weather in the step 1) is the sunny weather in March to May.

[0052] The tea buds grown from March to May are the freshest and tenderest, with good taste and high beneficial ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com