Fire-extinguishing projectile throwing system and throwing method for single soldier equipment

A technology for fire-extinguishing bombs and equipment, applied in the field of fire-extinguishing bomb throwing systems, can solve the problems of high operation risk, short throwing distance, low fire-extinguishing efficiency, etc., and achieve the effects of improving fire-extinguishing efficiency, large range and reducing work risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

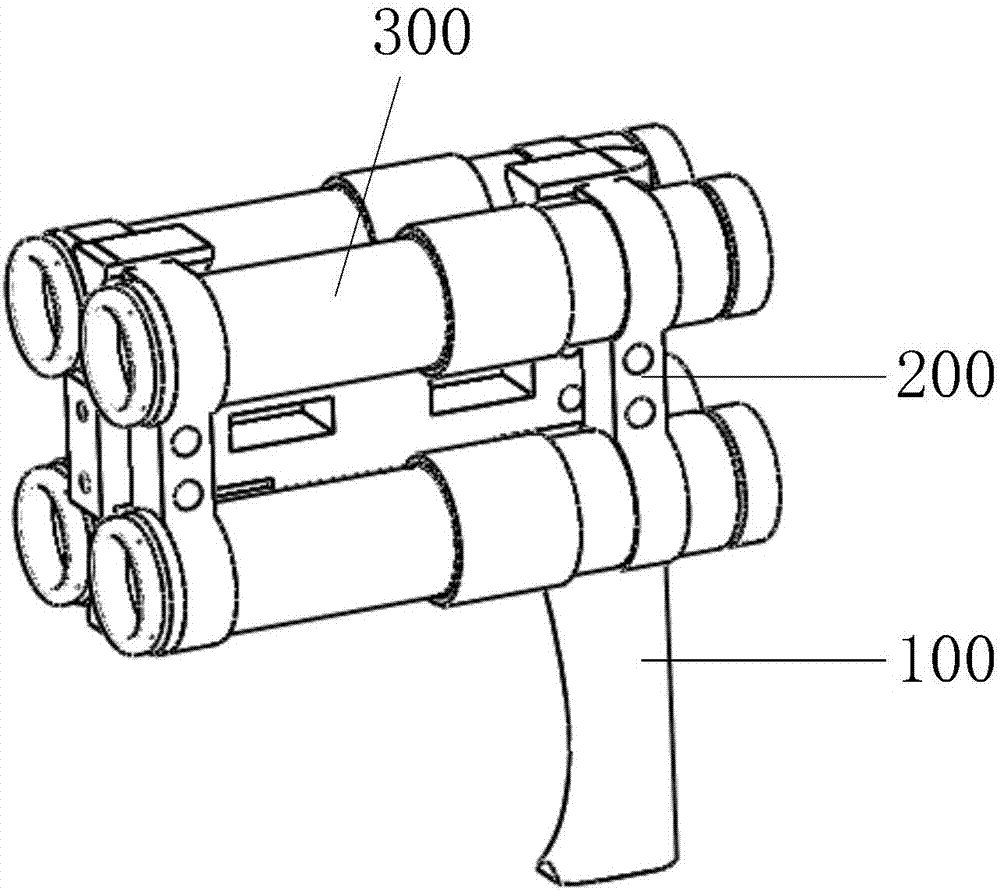

[0039] like figure 1 As shown, the fire extinguishing bomb throwing system of the individual soldier equipment of this embodiment includes: a launcher bracket, a fixed clamp, a launching tube and a fire extinguishing bomb; wherein, each launching tube is equipped with a fire extinguishing bomb; one or more launchers The barrel 300 is installed on the launcher bracket 100 ; the fixing clamp 200 fixes the launcher barrel 300 and the launcher bracket 100 .

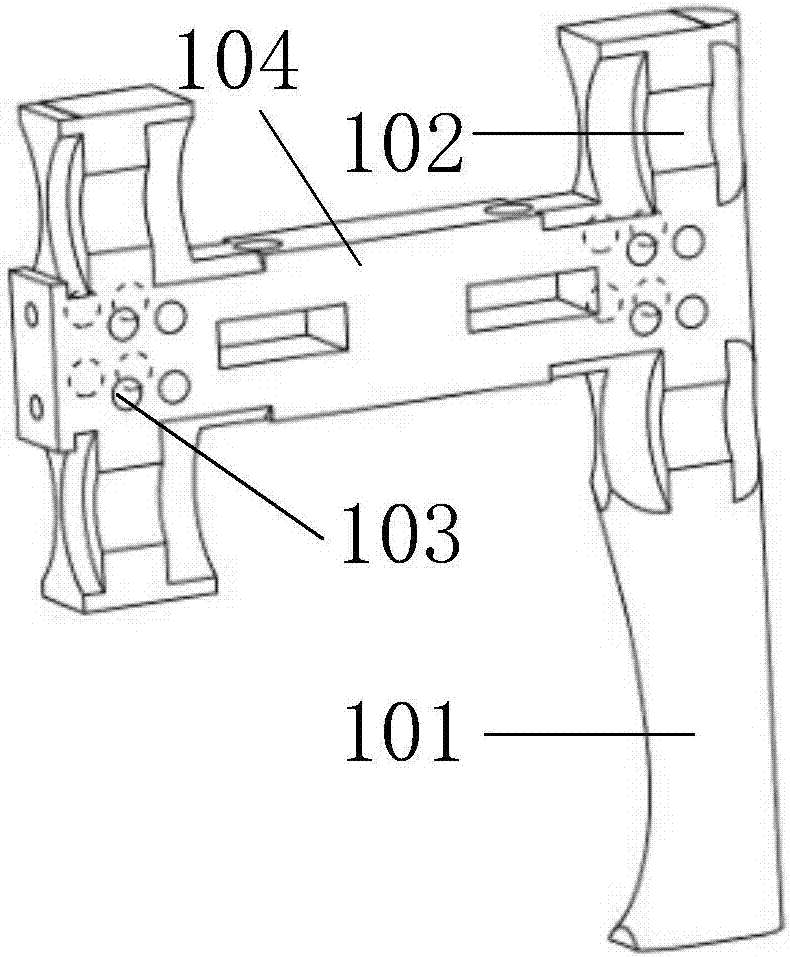

[0040] like figure 2As shown, the launcher bracket 100 includes a support link 104, a handle 101, a launch tube positioning groove 102 and a fixed clamp assembly threaded hole 103; wherein the handle 101 is provided on one end of the support link 104; One or more pairs of launcher positioning slots 102 launcher slots are matched with the launcher positioning slots, and each launcher is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com