Automatic feeding machine

A technology of automatic feeding and racking, which is applied to conveyor objects, transportation and packaging, grain processing, etc., can solve the problems of difficulty in adapting to market competition, increase in labor costs, and low production efficiency of manual operations, and reduce labor input. , the effect of realizing automation and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

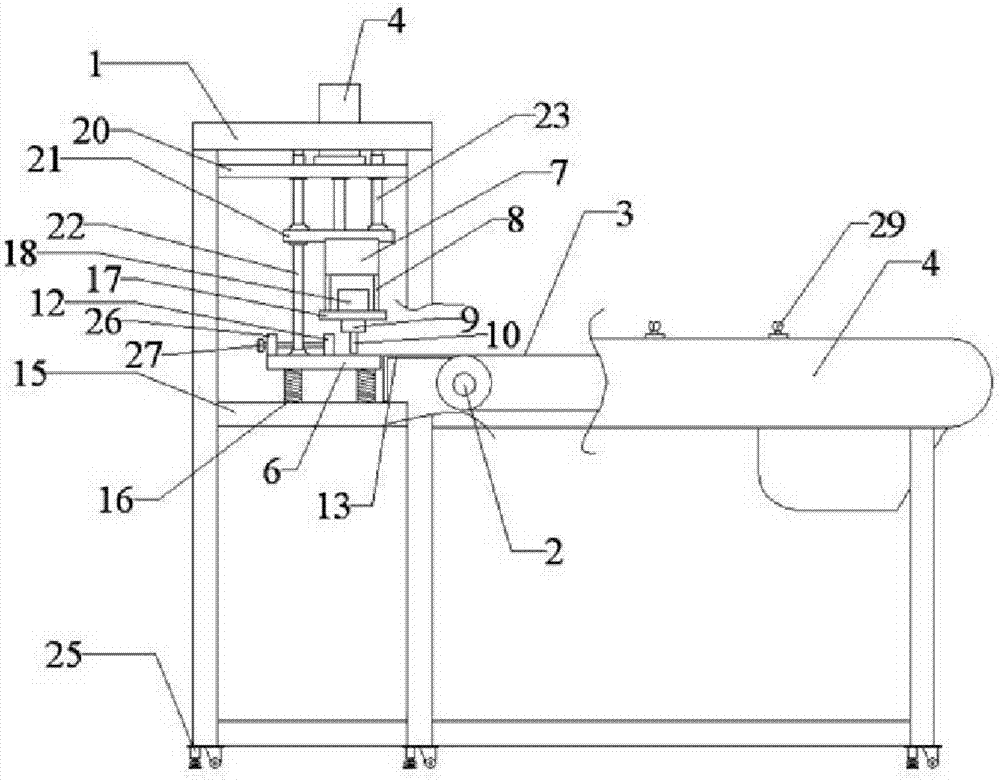

[0022] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

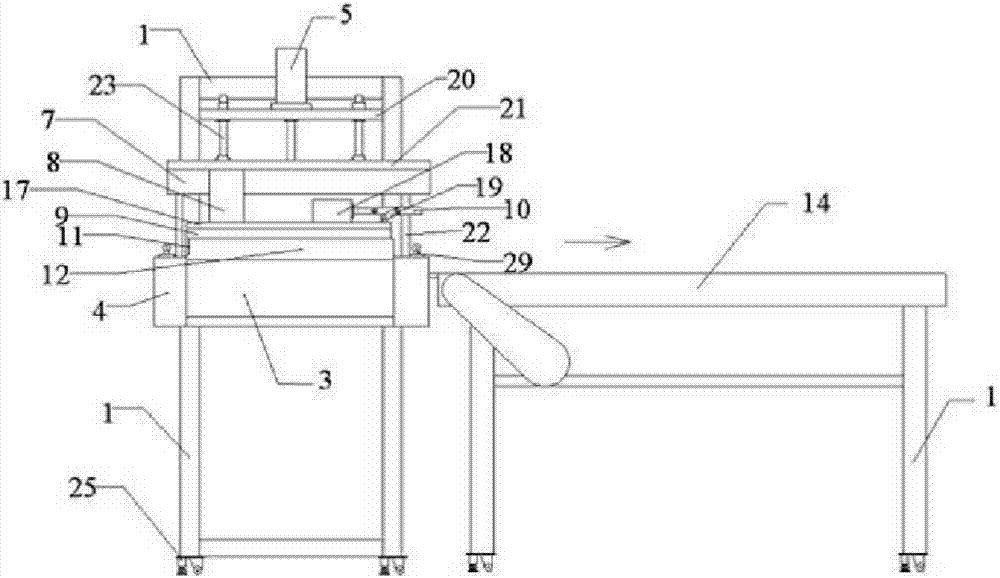

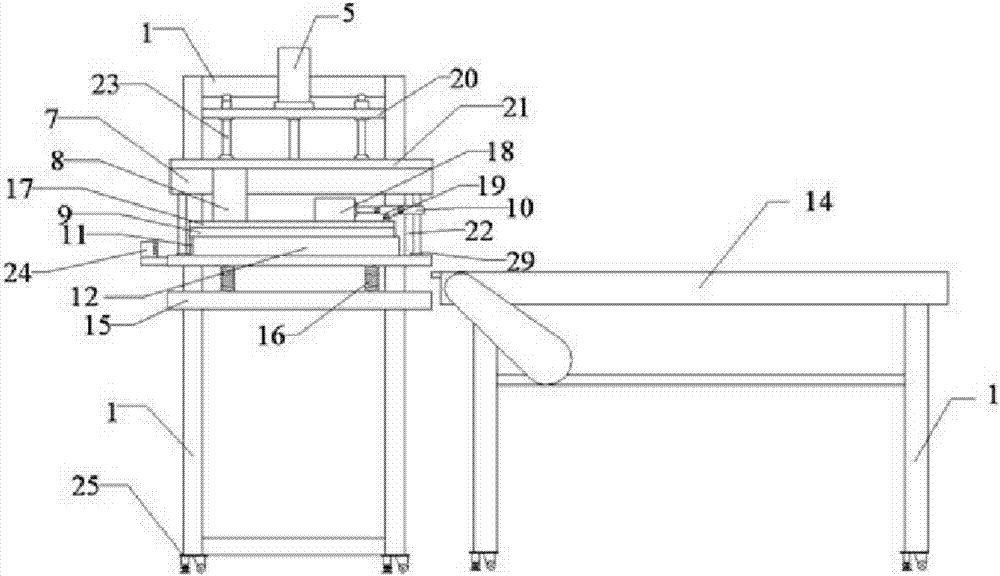

[0023] refer to figure 1 and image 3 As shown, the automatic feeding machine of the present invention mainly includes: a frame 1, a feeding device and a sorting device; as a preferred solution, it also includes a discharging device.

[0024] The rack 1 is mainly used to support and fix other components of the entire automatic feeder, and the feeding device is used to send the arrayed magnetic cores into the sorting device. The sorting device is responsible for removing one or several columns from the array. It is separated, sent to the discharge device and finally sent to the grinder to complete the feeding action.

[0025] As a preferred solution, in order to make the whole machine easy to move and fix, such as figure 1 , figure 2 , image 3 , Image 6 As shown, the frame 1 is fixedly connected with adjustable casters 25, such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com