Gravity type wharf structure combining buttress and caisson

A gravity-type wharf and caisson technology, which is applied in the direction of caissons, foundation structure engineering, quay walls, etc., can solve the problems of insufficient force bearing of buttress board members, poor overall stability, and extended construction period, so as to ensure anti-sliding stability, anti-sliding Strong anti-skid ability and speed up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

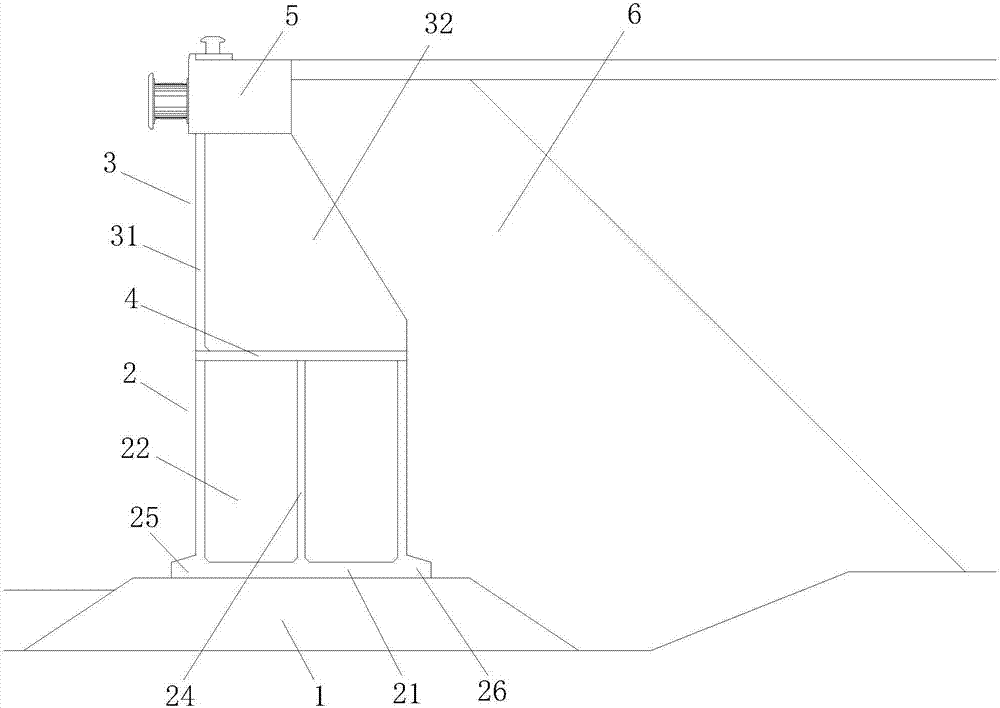

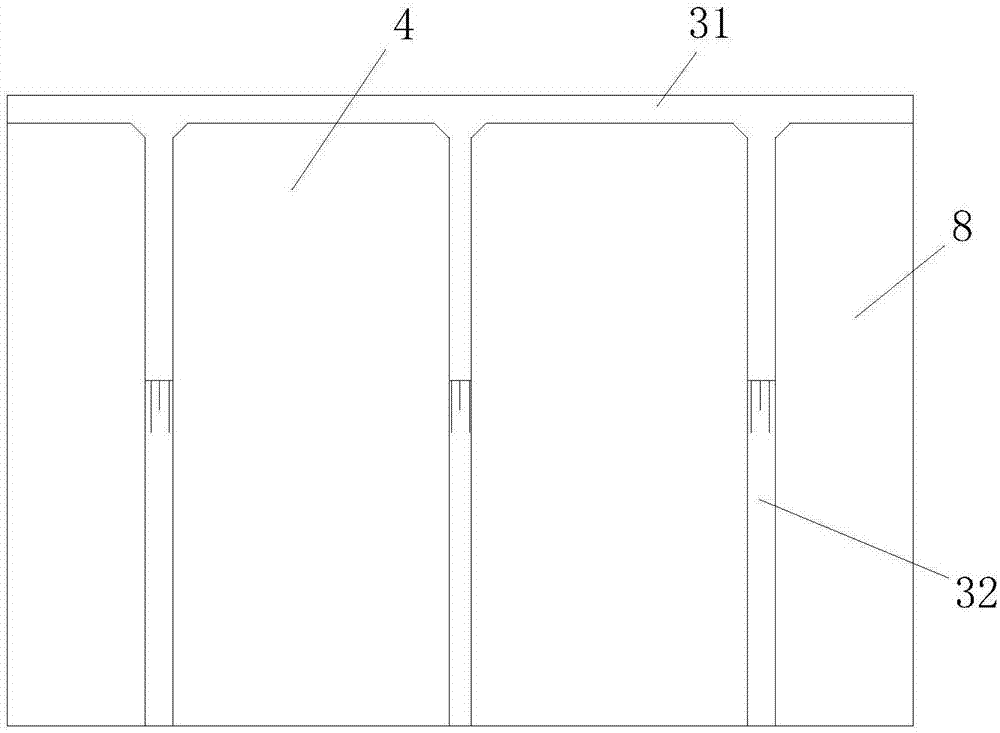

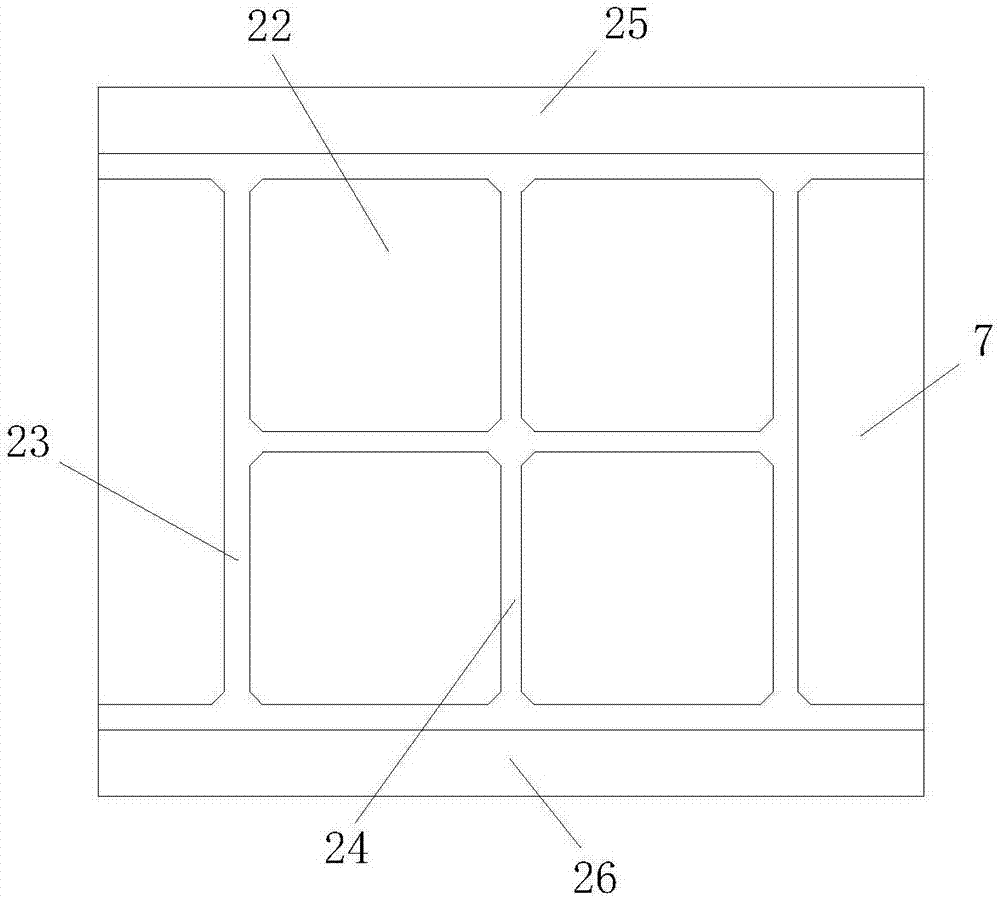

[0020] As an example, refer to figure 1 , figure 2 and image 3 , the gravity wharf structure combined with buttresses and caissons, comprising a caisson part 2 and a buttress part 3, wherein the caisson part 2 is arranged on the foundation 1, and the buttress part 3 is installed on the caisson part 2 to jointly form the main structure of the wharf, The rear of the caisson part 2 and the buttress part 3 is the rear backfill 6, and the breast wall 5 is connected above the buttress part 3; the buttress part 3 includes a front vertical plate 31 and a rib plate 32 at the rear, and the rib plate 32 is upright and fixed Behind the vertical plate 31 ;

[0021] The caisson part 2 includes several caisson compartments 22, the number of rows of the caisson compartments 22 matches the ribs 32 and does not exceed three rows, a row of caisson compartments 22 is corresponding between the two ribs 32, and each rib The plates 32 are all vertically aligned with the cell partitions 24 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com