FRP (Fiber Reinforce Plastic) and steel board combined type offshore collision preventing device

An anti-collision device and anti-collision technology, applied in shipping equipment, climate change adaptation and other directions, can solve the problem of high construction cost, achieve strong corrosion resistance, facilitate offshore operations, and good energy absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

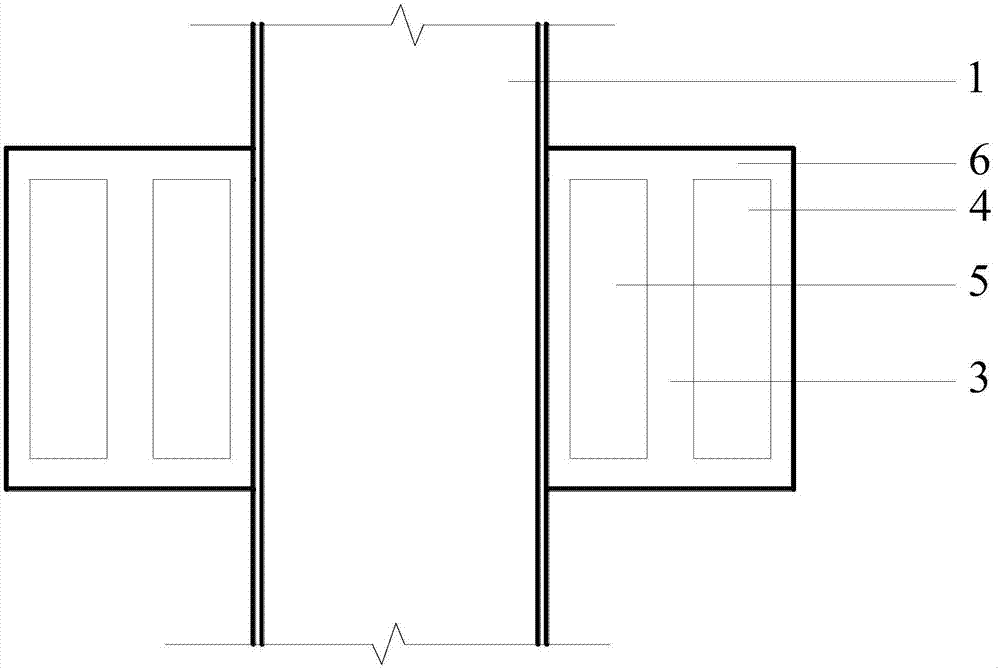

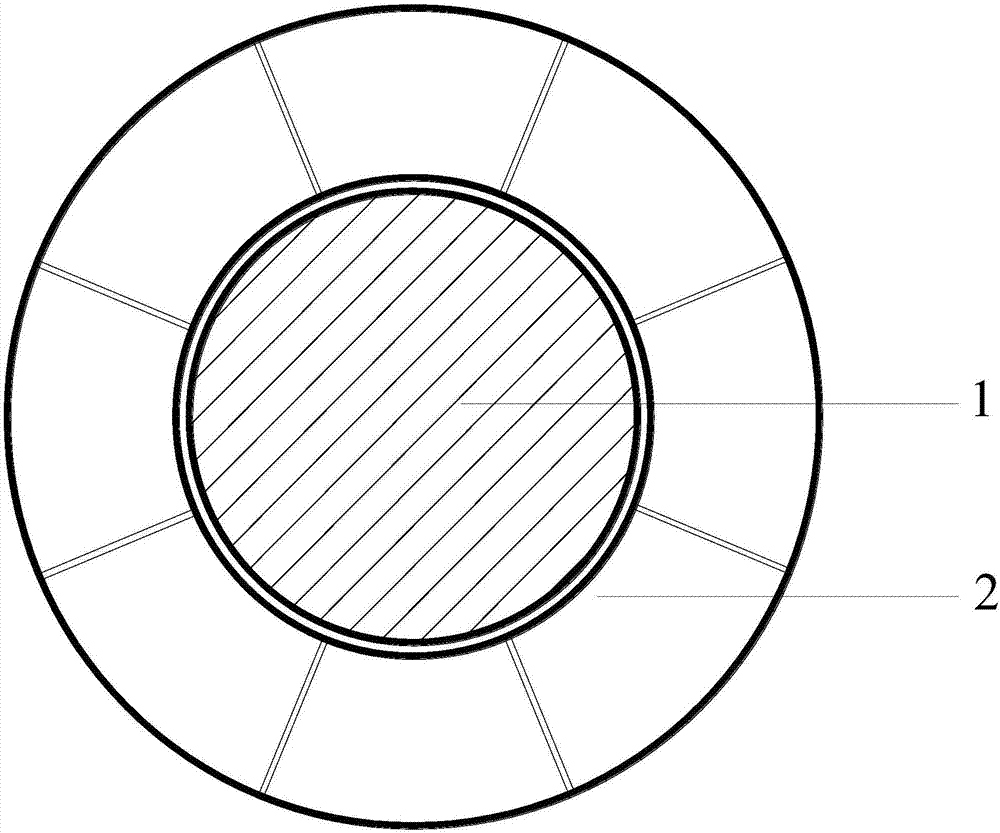

[0027] like figure 1 and figure 2 , a marine anti-collision device combined with FRP and steel plates, including a plurality of basic anti-collision units 2 and connecting pieces used for connecting between the basic anti-collision units 2, and a plurality of basic anti-collision units 2 surround a protected structure 1 Assembled. Connectors can be bolts, nylon rods or FRP pins.

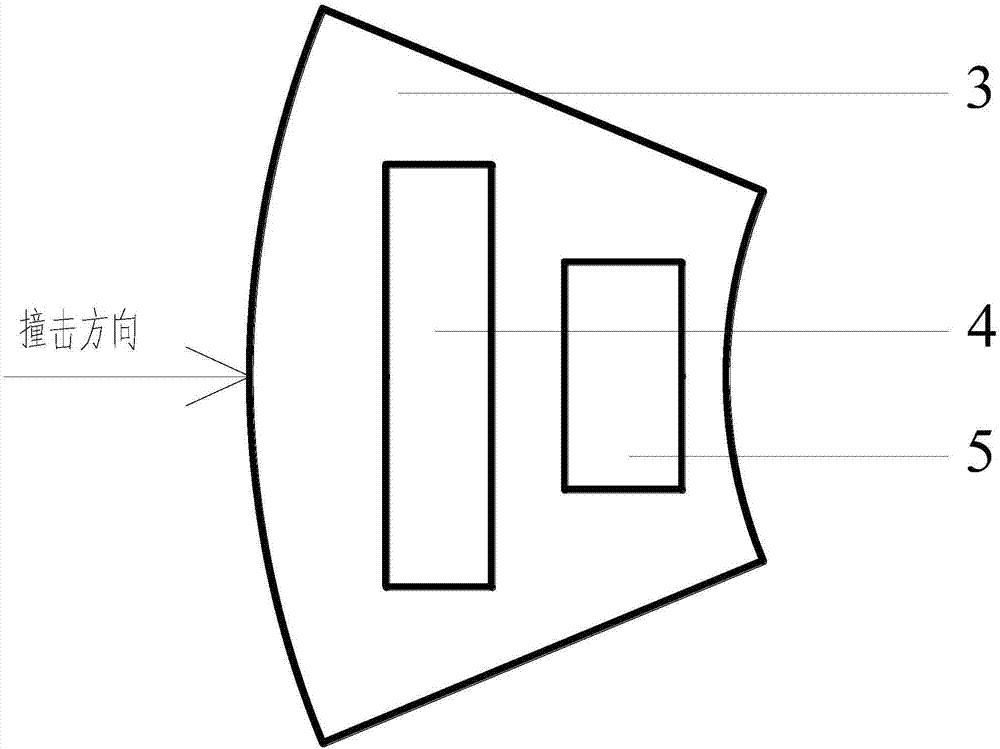

[0028] like image 3 , the basic anti-collision unit 2 is a fan-shaped cylinder, including an FRP shell 3, a corrugated steel plate anti-collision structure 4, an S-shaped steel plate anti-collision structure 5 and a top cover 6. Wherein, the corrugated steel plate anti-collision structure 4 and the S-shaped steel plate anti-collision structure 5 are embedded in the FRP shell.

[0029] The FRP shell 3 is made of FRP material. The interior of the FRP shell 3 is hollowed out into two parts, the outer side and the inner side. The outer side away from the protected structure 1 is used to embed the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com